Gun and crossbow: who is who?

The principle of operation is clear: the working fluid is compressed air, which pushes the harpoon out of the barrel.

Many models are equipped with a shot power regulator, which allows you to reduce it by almost half, for example, when there is a danger of damaging the harpoon on an underwater rock against which the prey is pressed. Here the harpoon is fired using the energy accumulated during the tension of elastic elements - rubber bands, analogues of crossbow arms, which are simply ineffective under water. The role of the bowstring is played by a V-shaped steel leash. It is clearly noticeable how the power is regulated on some samples: when shooting at small fish at close range, you can pull only one pair of strings, but if the situation changes, both.

And in our case, a whole series of devices where the arrow is thrown using compressed air is still not entirely correct to classify as crossbows. Let's look at an illustrative example - "Arcus Arrowstar". So:

“Arcus Arrowstar” (pictured) is produced by the Austrian arms company SEMEX GmbH, founded in 1994 and supplying, in particular, to law enforcement agencies.

The energy source is a 16-gram canister of liquefied carbon dioxide. It is possible to order an adapter for the much more familiar 12-gram one. The pressure regulator of the basic version is set to 48 bar, which allows you to fire about 20 shots with a muzzle energy of 10 joules (a 17-joule version is also available). For Germany, where there is a familiar limit of 7.5 J, the pressure is set using a special spring to 33 bar. This “F-variant” is capable of firing 40 shots at a projectile speed of about 40 meters per second.

Now about these shells themselves. The arrow weighs 9.5 grams and has a caliber of 5.9 mm. The fact is that in Austria there are no restrictions on muzzle energy for such samples, but there is a 6-mm license-free caliber threshold.

Why did we suddenly remember this not-so-new arrow launcher? Firstly, it is really quite original, nothing similar comes to mind. And secondly, our colleagues from the Kalashnikov magazine visited the IWA-2018 arms exhibition in Nuremberg and could not ignore the new product from SEMEX GmbH - the Viper large-caliber arrow launcher. The photo shows him in front of the Arcus Arrowstar.

And indeed, judging by the arrows presented here, the caliber is something like 9 mm, or even more. Alas, the manufacturer did not present any specific performance characteristics of the Viper. What is clear: if you look closely, you will notice the inscription “prototyp” on the body of the device.

PS But you haven’t seen yet another creation of the famous German inventor Jörg Sprave (more precisely, Sprave). By the way, it was from underwater guns that he created a six-barreled pneumatic crossbow - the original “Vulcan Phalanx” :)).

Update, December 2022

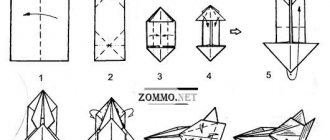

DIY spring crossbow

This description does not have the purpose of creating a weapon - using the described method, a tool for entertainment is made.

- The blank is given the shape of a bed - rectangular or round, long or short, at the request of the master. A pair of corners are attached to one end of the resulting workpiece.

- 2 holes are made in the plank (with dimensions of about 5x2 cm), after which it is secured with a pair of screws on a 10 cm piece, measured from the edge with the corners.

- In 2 new strips (with dimensions 15x3 cm), 2 holes are drilled into which metal tubes of suitable diameter are installed; they act as bushings (select optimally for the diameter of the bolts).

- At the middle of the longitudinal sides of the planks, one wire arch is fixed. They will further serve for mounting the springs.

- The strips also have holes for installing rollers - at the ends opposite from the mounted bushings. Rollers are installed in these holes. They are available in sufficient choice on the automotive markets.

- For installation, bolted connections with a diameter suitable for the roller holes are used.

- The assembled arms are mounted on the stock - through holes on the bar already installed on it.

- 2 springs (elements of door and furniture structures, from car parts are suitable) are installed on prepared wire brackets and corners at the end of the bed.

- Another pair of rollers is attached in the same way to the third bar (with dimensions 7x3 cm). It is mounted on the other side of the bed, also 10 cm from the other edge.

- Another bar is installed between the finished shoulders. Her role is that of a guide. It is also possible to place a support for the leg - from the corner.

- The trigger mechanism is performed: a bowstring is put on through the rollers, which is pulled to the limit position, where a mark is placed on the stock. According to

a ready-made trigger mechanism is installed with a mark, or a device is mounted from improvised means. The essence of its work: when you press the trigger, a reciprocating movement of the stop is performed, when lifted, the bowstring attached to it is released.The device is mounted in the area of the handle, which is part of the stock or added additionally.

- After installing the trigger device, the string tension is checked. A small corner is attached to it to capture the thrown projectile.

- A quiver is also added to the assembled crossbow for ease of carrying: a bar with drilled holes for arrows or darts is attached to the lower part of the stock (the opposite side with respect to the side on which the bowstring will go) or the butt. It should be installed taking into account that protruding projectiles do not interfere with cocking the crossbow and its use.

- An optical sight is added to the almost finished crossbow. The specificity of a shot from a crossbow allows its use: shaking of such a simple weapon will be performed after the projectile has fired, resulting in fairly accurate aiming.

Pneumatic line throwers

In addition to the semi-toy samples described above, there are very serious products that perform no less serious tasks. These are, first of all, various kinds of line throwers, used, for example, when mooring ships or by rescuers (pictured is the rescue pneumatic line thrower “Filin”).

His throwing range is limited by the length of the line - 100 m, no matter vertically, horizontally or at any angle.

There are longer-range analogs, for which we are talking about hundreds of meters, for example, like the ISTA-240.

The firing technique is very similar to that of anti-tank grenade launchers.

Homemade crossbow for spearfishing

Homemade underwater crossbow (in the process of manufacturing)

Depending on the size and power of the weapon, the harpoon has different lengths and thickness. The hooks on it are of the cut or sharpfin type. The dihedral shape of the harpoon blunts less, while the trihedral shape has a higher penetrating ability. The design of the handle on a homemade crossbow is an individual matter; it may not exist. If you plan to hunt large fish, you must have a reel. It is most convenient to install the coil in the front end of the barrel.

Hunting pneumatic arrow throwers

Of course, gunsmiths could not ignore the pneumatic principle.

A few years ago, a slight stir was caused by information about the appearance on the market (albeit foreign) of a certain superweapon - Airrow Stealth Model 8S1P (pictured)

Either a CO2 cylinder or compressed air was used as an energy source. This example, costing under $2,000, sent a 16-inch 2512 boom (Easton XX75) at speeds of up to 600 ft/sec, or more than 180 m/sec. Such indicators are unattainable even for modern compound crossbows; 410 fps is still a kind of “ceiling” for production models.

One point was not at all clear - what to do with the plumage? For devices operating over short distances, it is not necessary, and under water it completely interferes. But for the stated speeds of Airrow Stealth, the distances must be hundreds of meters. It was suggested that some cunning modifications of arrows were used here, which, like cruise missiles, opened the tail after leaving the barrel. As it turned out, the trunk was precisely the solution - it was no coincidence that manufacturers asked such sums for their products, since the design turned out to be very complex.

The same can be said about the new product on the market - the Pioneer Airbow arrow thrower from the famous manufacturer of air rifles and pistols, also produced under the Benjamin brand.

This is a very real hunting machine, delivering a solid 450 fps, or almost 140 m/s, with a hunting arrow weighing 375 grains. These indicators are quite enough for this:

Moreover, the domestic armory (formerly Luftmaster), known for its Lesnik PCP rifles and the ultra-compact Anchutka, a new product on the market, began accepting orders for the Kashchei pneumatic arrow gun .

It is based on the same technical solutions as the Pioneer, only the price is completely different for obvious reasons. By the way, “Kashchey”, in order not to conflict with weapons legislation, is certified as a “device for installation, rescue and reconnaissance work in hard-to-reach places.” Well, that's not a bad idea. I know the developer a little, I saw test shootings - it’s impressive.

By the way, since August 2016, even ordinary serial PCP rifles can also be used to throw heavy hunting crossbow bolts (see “Air Arrows”).

General description of the design

This type of weapon is designed to fire short arrows or bolts. Its advantages are compactness, noiselessness, and relative ease of manufacture. The latter is the main driving factor for making crossbows with your own hands. You don’t need a set of professional tools for this – it’s enough to have basic tools for woodworking and metal.

But before you make a crossbow with your own hands, you need to study its design:

- Bed. All mechanisms and components are installed on it. It is made of hardwood, you can use a multi-layer base. The shape is as close as possible to a rifle, ensuring ease of holding and loading.

- The shoulders are needed to draw the bowstring. You can make a crossbow from a spring, but due to the strong tension force it will be inconvenient. In addition, its power will be higher than permitted. The shoulders are made of spring steel or ordered ready-made for a specific power rating. An alternative is to make a spring crossbow.

- Cross for attaching the shoulder. It is made of wood or steel, there is a mechanism for quickly dismantling the tension plates.

- The crossbow trigger locks the bowstring and releases it after the trigger is pressed. It is recommended to consider a safety mechanism.

- Tensioner. Necessary to bring the device into working condition. The mini crossbow is not equipped with a similar mechanism due to the weak drawing power.

It is important that the tension force does not exceed 43 kg. Crossbows above this value are prohibited in Russia. Which 12 gauge cartridges can be considered the best choice - manufacturers and characteristics

Unusual crossbows and bows

This role can also be played by rubber, like in underwater crossbows, or a spring. But the latter can be either ordinary twisted or gas, that is, pneumatic.

Spring block "Cobra"

And such devices really exist. I already mentioned one of them in the article about the vertical crossbow. This is an ultra-compact spring-block bow “Cobra” based on high-pressure gas springs.

The author is the famous designer of mechanical bows Bogdan. It took him many years to get to “Cobra”, there were also “Phantom”, “Rustle”, and only God knows the number of intermediate options. The speed characteristics of the product reach 85 m/s with a maximum tension force, which can be adjusted from 22 to 27 kgf. For such a tiny thing, this is very, very good.

Bogdan also had a spring-lever bow “Piranha” (not a blocker), and a mechanical bow “Shadow”, where rubber bands were used as elastic elements (pictured).

Tools and materials

To manufacture parts and assemble a crossbow, the following tools are used:

- hacksaws for wood and metal;

- knife, plane;

- sandpaper;

- drill-driver with replaceable attachments - drills and bits;

- pliers.

The basic materials and supplies you will need are:

- wood block for processing in the stock and butt;

- several wooden planks for structural elements;

- corners for furniture (variably - made by hand);

- metal tube, 1 cm in diameter;

- a pair of block-type rollers, about 5-7 cm in diameter;

- a pair of springs about 10 cm long and quite powerful;

- steel wire;

- durable rubber of square or rectangular cross-section - for the bowstring.

As the work progresses, self-tapping screws, bolts, and a small amount of tin will be used (one cut from clean lids for preservation will do).

Shoulders (arches)

The arms of a crossbow are the elastic elements of a bow that store the human mechanical energy produced during the draw for the subsequent shot. The shoulders are attached directly to the stock; on powerful crossbows - to the stock through a metal block (5). Crossbow bow designs are divided into traditional and compound bows.

Unknown racing motorcycles of the 2010s

In turn, the shoulders can be straight or curved (recursive), have a monolithic or separate structure.

The traditional design is a regular bow as we understand it, the ends of which are tied with a string. In the block design, blocks (round or eccentric) are fixed at the ends of the arms, through which the bowstring is passed. Due to these blocks, the process of cocking a crossbow is significantly simplified, while the power of the shot remains the same.

The most common materials for the production of shoulders are reinforced fiberglass, carbon fiber reinforced plastic, and duralumin. Previously, when materials were tight, old springs from Moskvich were used as a blank for the bow. Not only was such a crossbow incredibly heavy and massive, it was dangerous, since the steel tended to burst at the most inopportune moment, scattering sharp fragments in different directions. Therefore, subsequently they began to put a protective bandage on such bows, and then they completely abandoned this material.

The role of the machine in zeroing

Beginners in shooting always want to make this task easier for themselves; they use “available materials”: plywood, unnecessary pillows, shelves, chairs. All this is used to make gun stands. However, this structure constantly wobbles, only making it difficult to make an accurate shot. The basis for high-quality and correct zeroing is a special device for the shooting position. This designates a place for the person directly shooting and a place for the weapon.

A durable and fixed stop under the fore-end and stock allows you to ensure a constant position of the gun when firing, regardless of the shooter’s experience and number of shots. Only consistency in weapon behavior and uniform placement can guarantee accurate and effective shooting. All such required conditions allow you to create a machine.

He secures the weapon rigidly, by the stock. Specially installed stops allow the gun to roll back when firing. Supports are very popular among experienced athletes.

Crossbow pin mechanism

The pin mechanism is easy to manufacture. It's easy to do it yourself. How to make a pin mechanism? For the pin mechanism, you need to make a groove on the stock. The bowstring will be wound through this groove. A hole is drilled directly under the bowstring, into which either a wood or metal pin is inserted. A bar is attached to the bottom of the stock so that when you press on it, it presses on the pin. The pin, having thus received the command, pushes the bowstring out of the groove. The device is simple, easy to manufacture, but has many disadvantages: there is no safety lock in the mechanism, the trigger is heavy, and it also wears out quickly.