It’s not always possible to go to the store for glue, but you urgently need to glue something. Then the questions arise: what to glue it with? what to cook from? The way out is to make your own foam glue. For proper preparation, you need to study the practical guide and take into account what surfaces such an adhesive material can come into contact with.

A practical guide to making glue

The technology for preparing glue from foam plastic and gasoline comes down to the following procedures:

- We prepare the container for the glue; it needs to be washed and thoroughly dried in the sun;

- A small amount of solvent or gasoline is poured into the bottom of the jar, approximately 1/10 of the planned proportion;

- The first portion is filled with foam crushed into granules, approximately three times more than the amount of solvent poured;

- The mixture of glue, polystyrene foam and solvent is stirred vigorously to remove the released gases;

- Next, you can add polystyrene foam in pieces, embedding it in the adhesive mass. If necessary, add a mixture of gasoline and acetone in small portions.

The result should be a viscous and stretchy mass, with a consistency similar to shoe glue or very thick jelly. As soon as the glue has stopped releasing gas bubbles, you can begin gluing the surfaces.

Second recipe for foam glue

This method is practically no different from the previous one, with the only difference being that nitro varnish diluted with a small amount of acetone is used as a base.

As in the previous case, the foam is loaded into the varnish-acetone mixture in small portions and thoroughly mixed to get rid of bubbles and ensure complete dissolution of the polystyrene foam.

If the first recipe was used as a regular glue that can be used to glue wood and paper, then the second mixture is used mainly as waterproofing. It is very convenient to use glue diluted to the state of liquid sour cream to treat the floor, steps, handrails of a country porch, you can seal holes in the roofing material with glue and even glue the roofing onto the sheathing boards.

Sometimes, instead of pure varnish, nitro paint is used to dissolve the foam. The result is a fairly viscous glue that does not adhere very well to ordinary materials. Due to the lumpy nature and large amount of ballast filler, the strength of the adhesive mass is at the level of putty, and it also dries out and cracks after the material has finally set. A mixture of nitro paint and foam glue can be successfully used as a protective coating for painting metal and wood fences.

Two ways to use homemade glue

Foam-based adhesive material cannot be called superglue. Despite the ease of preparation and fairly cheap and accessible components, foam glue has several significant disadvantages:

- Limited shelf life of freshly prepared glue;

- Reduced strength of the adhesive seam. Foam glue turns out to be weaker than polyurethane or even rubber branded materials, so the amount of adhesive mass when gluing materials is increased by 2-3 times;

- The glue takes a long time to dry. Due to the thick glue seam, the place where the parts are glued takes at least a day to dry.

The most inconvenient thing to work with is that foam glue must be prepared only before direct use. It is known from practice that if you dissolve polystyrene foam in gasoline and leave the finished mass for 10-20 minutes, the quality of glue adhesion to the surface drops sharply.

The finished mixture absorbs water vapor very quickly, and even the naked eye can see how a film forms. Therefore, when gluing metal and plastic to a smooth surface, wipe the area where the glue is applied with acetone and connect the parts as quickly as possible.

Porous materials, wood, paper, brick, slate can be joined without any haste, the glue penetrates deeply into the pores, and the quality of the seam is at an acceptable level.

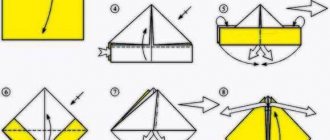

The second gluing method involves using fine foam powder. Ground polystyrene foam is poured onto the gluing area and covered with synthetic fabric. Using a brush or swab, a solvent - gasoline or acetone - is applied to the fabric and carefully rolled with a rubber roller.

Under the action of a solvent, powder foam dissolves in a few seconds, and the roller provides maximum pressure on the surfaces to be bonded. The fabric used as a backing remains in place where it is glued.

Making varnish: instructions

To prepare paint and varnish, you should take 70-100 ml of xylene, pour it into a container, occupying approximately 1/3 of its volume. To further reduce the cost of the material, you can combine xylene and acetone (gasoline) equally, or then dilute the thick ready-made varnish with inexpensive solvents. Afterwards the procedure will be as follows:

- Take polystyrene foam and break it into small pieces. The finer the crumble, the faster the dissolution process will occur. The approximate amount of foam is 0.3 cubic meters. dm.

- Press down the foam with a wooden stick so that the pieces are immersed in the liquid. The material will immediately begin to dissolve and gas bubbles will appear on the surface.

- You can add more polystyrene foam so that the consistency of the product resembles sour cream or liquid honey. High-quality varnish flows from the stick like a thread and does not separate into drops.

- Cover the varnish with a lid and leave for 20-60 minutes to infuse. The color should remain transparent.

- Strain the container through cheesecloth. Pour the clean composition into a new container that has a stopper and lid.

Brushes or spatulas are used for varnishing. You can simply pour the paintwork onto the surface and smear it with movements in different directions. The drying time for this product is 5 minutes after application at room temperature. The product can be used after an hour, when complete curing is achieved.

It is recommended to use the finished product for the following purposes:

- varnishing of wooden products;

- increasing the moisture resistance of concrete;

- coating of any painted objects.

You can also make other paints and varnishes using foam varnish. For example, if you introduce small wood shavings into it, you will get a reliable putty for holes, chips, and cracks. You can also make a conductive varnish. To do this, special fine-grained components are introduced into the composition, which, after polymerization, form a film with excellent electrical conductivity. They are usually used on metal, glass, plastic, and wood.

For 100 g of finished paintwork material, add 15 g of powdered silver and fine-grained graphite. Mix the product well until a dark, thick liquid is obtained. Before use, the varnish should be shaken thoroughly so that heavy particles do not settle down.

Covering the concrete floor

Dissolving polystyrene foam in xylene

Note: I was also advised to use solvent 647, but I didn’t have it on hand.

I would like to see how it will behave, because car owners are interested in cheap varnish to cover the garage against dampness. I’ll start by dissolving polystyrene foam in gasoline. I should also check it in acetone and solvent, but I think that acetone dries too quickly.

- I pour 92 gasoline into a clean, empty metal can. You will need a little more than half the can of gasoline.

- I cut a piece of polystyrene foam approximately 1500 mm long and 40 mm thick into strips and lower them one by one into a jar of gasoline.

- The width of the strip should be chosen according to the size of the can. My goal is to see how the resulting composition will behave on concrete (I don’t need a lot of varnish).

- The foam easily fits into the jar, melts and compresses into a fairly dense lump at the bottom.

- The resulting composition has the appearance of a gel and is similar to napalm (when ignited, it immediately flares up, burns for a long time, and the flame is high).

- It is not possible to regulate the viscosity of the composition by adding gasoline - it reaches a certain thickness and the process stops there.

- I leave the jar for a while so that the air bubbles come out and all the pieces of foam dissolve.

- I take out the gel-like mass from the bottom of the jar and transfer it to another container.

- I clean the area of the concrete slab with a wire brush and blow off dust with a spray gun.

- I prepared a brush and a spatula for work, which I lightly greased with oil. This way the varnish will not stick. It turned out to be more convenient to work with a spatula.

- I pour the varnish onto the concrete and use a spatula to apply it to the surface using movements in different directions.

- After finishing the job, there is practically nothing left on the spatula.

When applying the varnish you immediately smell the smell of gasoline. I leave this area for about an hour to dry.

I will conduct the second experiment with xylene (one liter costs 110 rubles). If you cover the entire garage with this composition, then its cost will be 2.5 times more expensive than polystyrene foam varnish dissolved in gasoline.

- To dissolve in xylene, I chose denser and more expensive fine-grained foam, from which the protection of the computer system unit is made.

- When xylene is added to the jar, the foam dissolves almost completely, the viscosity of the composition becomes less, and the thick lump disappears.

- A composition of this viscosity can be applied in a much thinner layer. It looks like xylene is better for making foam varnish.

- I'll try using xylene as a wood varnish. I take a walnut branch peeled from the bark and apply a thin layer of the composition with a brush. It turns out very well, but you have to wait for the varnish to dry.

- I also apply a layer of composition onto the concrete with a brush. The layer turns out to be very thin and there are no air bubbles in it.

- I leave it to dry.

My first section did not dry completely within an hour - a film with a very large number of bubbles formed on the surface. Huge bubbles formed on the sides. To the touch it looks like the well-known packaging film with bubbles. However, as an option, this composition can be used after complete drying.

The area covered with xylene varnish turned out better. The composition is well absorbed into the surface of the concrete and looks like real varnish. The only negative is the high cost of xylene compared to gasoline. To reduce the cost, you can first dissolve the foam in gasoline, and only then add xylene and achieve the desired viscosity. It will be inexpensive to prepare a composition based on bottled xylene, which is sold in cans and costs less.

Note: the composition dried on wood in 10 minutes and is indistinguishable from real varnish. In the future, for an experiment, I can take a board polished on a machine from a nearby furniture workshop and apply 3-4 layers of xylene varnish to it.

Well, now it's time to finish the article. All the material I wanted to share has been reviewed. I hope it will be useful to you, and you will use it if you need to remove dust from a concrete floor with liquid glass with your own hands. Improve your own practical skills and gain new knowledge, as they say: “It’s never too late to learn!” That's all, thank you for your attention, successful and easy repair!

Modern adhesive compositions, of which there are many in construction stores, with all the variety of names and brands, are not much different from each other. All of them are united by a high price and average gluing quality. Most often, universal construction adhesive is a polyurethane or polystyrene viscous mass in an organic solvent. Foamed polystyrene, also known as foam and solvent, can be found in almost every home. Following the same logic, you can quite simply make foam glue with your own hands based on a simple recipe.

How to insulate a floor with your own hands

This work is carried out in two ways:

The wooden floor serves as additional thermal insulation. In addition, it is preferable if communications are laid underneath it. In the event of their repair or forced replacement, dismantling the floor covering and performing the work will be much easier, faster, and cheaper.

Wood flooring in a garage is one of the most common options.

It is important! When choosing the second method of insulation, it should be taken into account that in this case the floor rises to the height of the log with the thickness of the boards. If the room is low, this thermal insulation option will cause inconvenience in the future use of the garage.

Expanded clay for concrete floor

The work is performed in the following sequence:

When insulating a concrete floor with expanded clay, it is important to follow the technology

Attention! The hardening time of the concrete floor is 28 days.

Expanded clay under a wooden floor

Expanded clay is one of the most affordable and easy-to-use materials

Expanded polystyrene under the screed

Both polystyrene foam and polystyrene foam of the PSB-S-35, PSB-S-50 brands, which have sufficient compressive strength, are suitable for this method of thermal insulation.

You can also dig a pit or lay insulation on an existing screed, if the height of the garage allows (the floor will rise by about 20 cm).

In the first option, the sequence of work is as follows:

Expanded polystyrene is one of the most popular insulation materials; it is suitable for any covering.

To check whether the screed is dry or not, you need to place any container turned upside down on it overnight. If moisture has accumulated under it in the morning, the floor is not yet dry.

Video: Insulating foam under screed

Polystyrene foam for wooden floors

In this option, the insulation is placed on the old screed. This method is popular among car owners because you can use even the cheapest PSB-S-15 foam plastic with a thickness of 50 mm, since there is no load on it, and the wooden flooring acts as additional insulation. In addition, the floor rises by a maximum of 10 cm.

Even cheap polystyrene foam is suitable for insulating the floor in a garage.

It is better not to use tongue and groove boards. Under these operating conditions, they quickly deform.

How to make linoleum glue

The step-by-step instructions are as follows:

Remove dust and other dirt from the coating. If you do not maintain cleanliness, then foreign impurities may form in the future glue. They will only interfere with the work process. If liquid detergents were used for cleaning, the flooring should be wiped with a dry cloth and allowed to dry thoroughly. Cut it into small pieces. To do this, you can use sharp scissors or a knife. The smaller they are, the faster they will dissolve, and accordingly, the less time it will take to get the finished product. It is advisable to cut the linoleum into fragments of 0.5 centimeters or less. Place the chopped pieces in any lined jar

Please note that this container must be tightly closed, clean and dry. Do not use plastic under any circumstances - acetone will dissolve not only the flooring, but also the container. Fill everything with solvent

There are no exact proportions here. You just need to make sure that the liquid completely covers the linoleum. Close the container. If it seems that it does not close tightly enough, then you can put a PET bag or a piece of film under the lid. Dissolution will begin almost immediately. But the final result will be achieved within 10-24 hours. The amount of time depends on how finely the coating pieces were cut. But it is better, nevertheless, to withstand the maximum amount of time. After the jar with the “mixture” is closed, set it aside and shake the contents periodically. “Shaking” can speed up the process and make the mixture more homogeneous.

Do I need to insulate the floor in the garage?

There is an opinion among experts that the optimal temperature in a private garage in winter should not exceed +5⁰ C. If a car is driven from the cold into a room with a higher temperature, condensation forms on the body, and air humidity rises sharply. This negatively affects the anti-corrosion properties of the car and shortens its service life.

Many drivers consider the thermal insulation of the garage floor unnecessary, limiting themselves to insulating the doors, walls and ceiling. In such a situation, the owner of the building will experience constant heat loss through the floor covering. Maintaining the optimal temperature in the room will require a lot of energy. In addition, during severe frosts, condensation may form at the point of contact of the cold floor with warm air.

It is important! SNiP 21-02-99 “Car Parking” states that the minimum recommended temperature of a car storage room should be +15⁰ C. In this case, it is taken into account that there is forced ventilation in the garage and maintenance and repair work is being carried out on the vehicle.

By insulating the floor, the owner creates favorable conditions not only for storage, but also for servicing his car.

Floor insulation is an important stage in arranging a garage.

Dissolve polystyrene foam in solvent - All about insulation and energy efficiency

In the house, sometimes an adhesive composition is required for repair work. Buying the necessary product in building materials stores is not always pleasing with the price-quality ratio.

It is easier and better to make a homemade adhesive composition from polystyrene foam.

A simple recipe will reveal useful secrets: how and with what to dissolve the foamed polymer to create a viscous adhesive mass.

Using homemade glue

at the beginning of preparing a homemade product, you need to learn which objects can be glued together, and for which material it is not suitable.

Connecting only rigid objects will be successful, since the adhesive mass hardens, increasing the strength of the product. You won't be able to seal a crack in a flexible rubber boot with a homemade product.

The specificity of the use of glue is the limited time of its use - 10-15 minutes after preparation, later the quality of the adhesive mass decreases.

Due to this, the product is required for small and urgent work:

- sealing fiberboard joints;

- repair of floors, roofs made of tiles or asbestos-cement corrugated roofing sheets;

- gluing furniture, baseboards, interior items;

- hydroprotection of the base;

- fastening cornices;

- insulation of loggias, balconies, ceilings and floors, foundations, walls with extruded polystyrene foam.

Owners of garages, garden houses, and private homes will often be helped out in everyday life by a simple and quick-to-prepare handmade adhesive composition instead of expensive casein and carpentry adhesive.

Related materials

Making a homemade adhesive requires only two main ingredients: a foamed polymer and an organic solvent.

Two main ingredients: foam polymer and solvent

Thrifty owners know where they can always find different pieces of expanded polystyrene:

- in packaging boxes for current devices - used as an anti-shock agent during transportation;

- remains of sheet-type material (clippings or crumbs) used as a heat insulator in the process of cladding the premises;

- old foam trays, plates, glasses - were used everywhere in the past.

Packaging and containers made of polystyrene foam

— how to cut foam polymer. Detailed note.

Foamed polymer comes in different qualities, as this term refers to a whole group of materials obtained by various methods of foaming the initial substance. There are 4 types of polystyrene foam:

- pressless - products made from most bonded balls. When pressed, the material crumbles;

- pressed - a dense product with very high strength;

- extruded - material with a solid structure;

- granular - a bulk material that consists of a majority of very small grains.

Before preparation, samples of different types of polystyrene foam can be loaded into gasoline for comparison. The distinct result will reflect a very effective dissolution of granular and pressless material.

It is important to take into account that the foamed polymer for homemade glue must be clean, without fire-retardant additives, and without an unusual odor.

Solvent

There is always some kind of solvent in everyday use. In preparing glue you can safely use:

- acetone;

- thinner for nitro paints;

- purified gasoline "Galosha";

- automobile gasoline:

- Vietnamese gasoline (with the addition of acetone).

Gasoline grades with an increased content of fuel alcohol and additives are not suitable. It is not recommended to dissolve with dichloroethane, benzene, toluene - these substances with high toxicity of aromatic hydrocarbons. Although they are considered optimal solvents, inhalation of vapors during stirring leads to poisoning.

Equipment

In addition to the components to prepare the glue, you will need:

- Capacity. The first portion can be diluted even in an ordinary bowl or jar. It is convenient to dilute a significant volume of adhesive mass in an iron canister.

- Gloves.

- Fan. When mixing elements, gases are released (freon, styrene, etc.), which are not recommended to be inhaled.

Cooking recipes

There are two key recipes that skilled home craftsmen use.

The first method consists of the following step-by-step steps:

prepare a container for mixing the components - it must be clean, dry, the volume depends on the required mass of glue;

What is needed for cooking

The main components are foam and solvent. This method is cheaper than store-bought formulations and turns out to be more reliable in terms of results.

In addition to the listed components, you need to prepare:

- a clean metal container (preferably a canister);

- gloves to protect hands;

- home fan;

- a spatula or stick to thoroughly mix the composition.

For the first time, it is better to make the solution in a small amount, for example, in an ordinary half-liter glass jar. A switched on home fan will prevent burning if a lot of mixture is being prepared. Protective gloves will protect the skin of your hands. The best type of solvent to choose is toluene or benzene. They cannot be used at the same time. Increased toxicity of substances can make the adhesive composition itself toxic.

Which foam to choose

It is better to take polystyrene foam from packaging materials for household appliances, the remains of a heat-insulating layer in an old refrigerator, or part of sheet insulation. Crumb will also work. There must be a lot of the substance itself, since 95% of its composition is gas. Among the main requirements it is necessary to highlight:

- cleanliness of the material (no dirt, dust, or other residues);

- refusal of materials for thermal insulation of underground communications, which contain fire-fighting additives and a specific odor.

Before use, everything must be ground to a powdery mass. This also applies to polystyrene. First you need to mix the crushed polystyrene with a small amount of acetone, and only then you can add polystyrene foam and gasoline.

During cooking, gases (styrene, freon) are released, which do not affect the effectiveness of the composition, but can cause poisoning if they are inhaled.

It is better to choose non-pressed polystyrene foam itself (in the form of connected balls that easily fall apart and crumble). It dissolves most easily in acetone and gasoline, forming an adhesive composition.

How to dissolve polystyrene foam to make glue

Almost any type of solvent is suitable for the job, but it is better to choose pure gasoline (A-95) or acetone. Suitable thinner for nitro paints or P646.

It is better to refuse to dissolve with leaded varieties and gasoline with bioadditives, where the concentrate of fuel alcohols, for example, kerosene, is too high.

- Can be dissolved with Vietnamese gasoline. It is effective and safe. Contains acetone.

- You can use acetone or dichloroethane itself. The second option is dangerous due to its toxicity, but it firmly glues any plastic surface.

If you prepare the composition from acetone and polystyrene foam, then the consistency itself will be softer and more fluid. This helps in more even application.

Instructions for preparing linoleum glue

Linoleum is not only a beautiful, practical floor covering. There is a recipe for universal glue; it is prepared from the remains of old flooring. Making this home remedy is quick and easy; no special ingredients are required. Do-it-yourself linoleum glue is a reliable, strong composition that is suitable for joining the following materials:

- ceramics;

- metal;

- wood;

- plastic;

- glass;

- rubber;

- cardboard;

- paper;

- porcelain.

The components for making glue are linoleum scraps and acetone. You will also need a 1 liter or larger glass jar with a tight-fitting lid.

There is an important condition: if the flooring is without a backing, it is used in its original form. If there is an insulating layer, it must be torn off

Step-by-step manufacturing technique:

- Wash a piece of flooring with soap. The material must be completely clean.

- Dry the linoleum by wiping with a cloth. Cut into small pieces (a few millimeters) with a sharp knife or scissors.

- Take a dry, clean jar. Fold in the cut pieces.

- Fill the material with acetone so that it completely covers the trimmings.

- Place the closed jar in a dark, not cold place.

Linoleum begins to gradually dissolve in the solvent, the whole process lasts about 24 hours. The more often you shake the contents of the jar, the faster the composition will be ready. Within a day you can glue any surfaces or parts with it. To do this, apply a little product to the base, spread it in a thin layer, press the product and fix it.

This glue is easy to use - it dries as the acetone evaporates in a few seconds. Add an equal amount of wood chips to create a quality wood putty or window putty. The introduction of chalk (1:1) will allow you to prepare an excellent mastic for laying tiles. The cost of such glue is very low, and the quality is not inferior to store-bought, so it can be used everywhere.

Why is it important to treat the concrete surface with soil?

Many people mistakenly believe that protecting a concrete foundation is not necessary.

However, despite the fact that concrete itself is a very durable material with a long service life, it is also susceptible to various aggressive environments and loads.

What does priming a concrete surface provide:

Considering the above, we can conclude that treating the floor, walls, ceiling, and other concrete bases with a primer is necessary. Requirements for materials for protecting concrete are set out in GOST 31384-2008 “Protection of concrete and reinforced concrete structures from corrosion.”

What does polystyrene foam dissolve in, how and with what do you dissolve polystyrene foam?

Households often require glue for repair work. Buying the necessary product in construction stores is not always pleasing with the price-quality ratio. It’s easier and more reliable to make homemade foam glue. A simple recipe will reveal little secrets: how and with what to dissolve the foam to create a viscous adhesive mass.

We do it ourselves: quickly and inexpensively

Using homemade glue

Before you start preparing a homemade product, you need to understand what objects can be glued together and what materials it is not suitable for.

Connecting only rigid objects will be successful, since the adhesive mass hardens, increasing the strength of the product. You won't be able to seal a crack in a rubber boot that is flexible at the break with a homemade product.

The peculiarity of using glue is the limited time of its use - 10-15 minutes after preparation, later the quality of the adhesive mass decreases.

Therefore, the product is required in cases of small and urgent work:

- sealing fiberboard joints;

- repair of floors, tile or slate roofs;

- gluing furniture, baseboards, interior items;

- basement waterproofing;

- fastening cornices;

- insulation of loggias, balconies, ceilings and floors, foundations, walls with extruded polystyrene foam.

Owners of garages, garden houses, and private houses will more than once be helped out by simple and quick-to-prepare homemade glue instead of expensive casein or carpentry glue.

Styrofoam

Thrifty owners know where they can always find various pieces of foam:

- in packaging boxes for modern devices - used as an anti-shock agent during transportation;

- remnants of sheet material (clippings or crumbs) used as insulation during the finishing process;

- old foam trays, plates, cups - were widely used in the past.

Packaging and containers made of polystyrene foam

- how to cut polystyrene foam. Detailed article.

Polystyrene foam comes in different qualities, as this term refers to a whole group of materials obtained by different methods of foaming the original substance. There are 4 types of foam:

- pressless - products made from many connected balls. When pressed, the material crumbles;

- pressed – a dense product with increased strength;

- extrusion – material with a solid structure;

- granular - bulk material consisting of many small grains.

Before preparation, samples of different types of foam can be immersed in gasoline for comparison. The visual result will reflect the most effective dissolution of granular and pressless material.

It is important to take into account that the foam for homemade glue needs to be clean, without fire-fighting additives, and without a specific odor

Safety regulations

The use of foam glue requires compliance with fire safety rules, because the mixture ignites quickly and burns for a long time. Even a lit match can cause a fire. When heated, the mass releases a significant amount of heat and produces thick black smoke.

It is recommended to carry out work on the production of glue in the open air, so as not to harm health by inhaling the released vapors and gases when mixing polystyrene foam with gasoline or other solvent.

Roof repair with foam glue

The method of preparing glue from materials that can be found in any home is practical and simple. Following simple rules will help you carry out routine repairs safely, quickly and inexpensively.

Dissolving foam

Polystyrene foam (polyethylene) is an organic thermoplastic solid with a low melting point; Polystyrene foam is widely used in the packaging, food, automotive and printing industries. Polyethylene comes in two forms—high-density polyethylene and low-density polyethylene. Both forms of polyethylene are highly resistant to acids, alkaline mixtures and inorganic solvents.

Benzoyl, if necessary, can replace acetone to dissolve the foam.

Disadvantages of foam glue

- Homemade foam and solvent glue has a very limited shelf life.

- It is characterized by reduced strength of the finished seam.

- To obtain sufficient reliability of the connection, you need 2-3 times more glue.

- The glue itself takes longer to dry (at least a day), so it must be used immediately after preparation. After 10-20 minutes, the quality of bonding of parts will be lower. This is especially true for preparing glue using gasoline. Metal and plastic smooth surfaces must be connected immediately.

- If porous materials are processed, for example, wood or brick, then the first layer of the composition must be allowed to absorb.

If the mixture is prepared with the addition of gasoline, then it is better to use it for outdoor work, for example, waterproofing the basement line of walls. It is better to carry out all work away from sources of fire and sparks. It is necessary to avoid preparing the mixture near heating devices that are turned on.

There are situations when you need to glue something together, but you don’t have the necessary product at home. It is not necessary to buy an adhesive composition. You can always make it yourself if you have the simplest materials. “Folk craftsmen” make glue from polystyrene foam and solvent. The result is a product no worse than store-bought, suitable for a variety of purposes.

In cosmetics

Dimethyl ketone is the main ingredient in traditional nail polish remover. If you think it might cause damage, you can replace the acetone with non-acetone nail polish removers that contain ethyl acetate. The first does a better job of preparing the surface of the nail plate for coating with varnish and the varnish holds better, while the second does not dry out the nail.

Interestingly, ethyl acetate is used as a replacement for acetone for flushing a car engine - decarbonization does not require special knowledge, even a novice car enthusiast can cope with this process.

Adhesive for polystyrene foam

When installing thermal insulation, polystyrene foam is easy to process, fit, and install. It is recommended to use a combined method of fastening - additionally secure the slabs installed on glue with dowels. Since various types of solvents (gasoline, acetone, ethers) dissolve polystyrene foam itself, adhesives based on them cannot be used.

There are bitumen-based mastics and cement-polymer mixtures specially designed for polystyrene foam. These compounds provide a reliable connection to almost any base - concrete, brick, various types of blocks, plasterboard and perform the function of additional waterproofing.

If there are no special requirements for installation technology, and depending on the scope of work, you can use many of the available adhesive materials - silicone sealant, liquid nails, tile adhesive. When installing ceiling skirting boards or moldings, a spot or thread application of glue is sufficient, so a tube of sealant or liquid nails is more than enough to install them in a standard apartment. The technology for applying tile adhesive is the same as when installing tiles - apply over the entire surface and remove the excess with a comb spatula.

What type of foam can be used to create glue?

Polystyrene foam is a room insulation material that has a foam structure. There are three types of material:

- Unpressed. The structure of such a sheet is represented by interlocking balls, which are easily detached under mechanical influence. This type is used to prepare adhesive. It is easy to melt in gasoline and acetone until a sticky mass appears.

- Compressed. This type has a strong structure and does not crumble when exposed to impact, since sheet pressing is used in production.

- Extrusion. In this form, the homogeneity of the raw material can be traced, since the production method uses the method of elevated temperatures.

What tools and equipment will be required?

To prepare polystyrene foam varnish, you will need the following raw materials and equipment:

- polystyrene foam (there should be a lot of it);

- dissolving liquid (one of the types or a combination of them);

- dishes for dissolving (any large glass, tin or polyethylene container with a wide neck will do);

- wooden stick for stirring;

- filter for straining (you can use a plastic strainer, gauze, a piece of tulle or old nylon tights);

- storage container with a hermetically sealed lid.

In addition to equipment, you need to stock up on a respirator, safety glasses, rubber gloves and long sleeves. Contact of solvents on the skin, and their vapors on mucous membranes and lungs, is undesirable, since they contain toxic substances. When foam bubbles collapse, they also release gases, the inhalation of which can cause poisoning. Work should be carried out in a well-ventilated non-residential area (garage, workshop) or outdoors. If this is not possible, then the solution is prepared on an open balcony.

Applying primer to concrete base

The video in this article will help you get more information.

The process of treating a concrete surface with soil with your own hands is quite simple, and anyone can handle the work, even those who have never taken part in finishing work.

Elimination of concrete surface defects. Applying a primer to the concrete surface

As can be seen from the article, a primer for concrete surfaces is an indispensable condition for the installation of a high-quality and durable coating and protection of the concrete base. There are many types of compounds on the market, so when choosing, you should carefully study their characteristics to ensure they meet your requirements.

Foam Varnish for Concrete Floor Note: This will cause the gasoline to bubble and splash out of the can.

How foam is glued to different surfaces

Depending on the type of work, foam plastic is glued to various surfaces. For example, when fixing to concrete walls, specialists use special foam. Since concrete walls are quite cold, they require insulation, and this material is ideal for this role. Foam glue is suitable when working with brick walls. This composition is a dry mixture, which the master subsequently dilutes with water. Dry mixtures are inexpensive and have low consumption. The specialist applies the finished composition to the wall or to a sheet of material, and the slabs themselves are glued from bottom to top.

Dry construction mixtures are used for gluing. Source obystroy.ru

You can use polystyrene foam glue or PVA construction adhesive. It perfectly fixes the material on metal surfaces. First, burlap is impregnated with this composition, applied to a metal surface and waited for drying. As soon as the layer has dried, fix the foam material. In order for the slab to better adhere to the base, after applying it, it is pressed against the wall. At this time, the glue increases its thickness, and the specialist glues the next slab.

Technology for gluing foam tiles

Polystyrene foam or polystyrene foam, their differences and which one is better

The most important moment at the time of pasting is the marking of the ceiling and therefore it should be treated with special responsibility.

All necessary measurements are taken using a ruler. How the tiles will be laid needs to be determined in advance.

There are several types of tile placement. You can glue it like this:

- in even rows;

- diagonally;

- with shift;

- parallel to the wall.

Sticking ceiling tiles can cause problems with the seams between the cards. To avoid such a misunderstanding, you should start from the center of the chosen room. In the middle of the room, axes are strictly marked, thanks to which the gluing of tiles begins from the center. Most craftsmen glue foam cards diagonally. This choice requires a completely different axis marking; they are marked from one corner to the other, maintaining an angle of 90˚.

An unclear corner can at one time fail in the middle of the laid out tiles. After applying the tile axle, we begin gluing. It is best to apply glue to the card so as not to cover the markings. If there is not enough glue on the tiles, then you need to treat the ceiling with glue

The glue is applied to the ceiling and tiles in opposite directions. The tiles with glue are applied to the ceiling and leveled using a level. It is best to stick a square in the center of the room and move from it in all directions. It is better to have cut tiles near the walls than in the middle of the ceiling. Having finished tiling the ceiling, make sure that all the cracks that remain between the joints are sealed. You can use acrylic sealant for this purpose. The glued foam tiles with neatly sealed seams must be painted with water-based paint.

Features of the composition

For preparing glue, a non-pressed type of foam or ready-made crumbs from it are best suited. This option melts faster than others, crumbles easily and, dissolved in gasoline, turns into a homogeneous viscous mass.

Before mixing, the foam is cleaned of dirt and dust. You also need to make sure that it does not contain impurities, including varnish and paint.

Useful: under no circumstances should foam plastic, suitable for insulating underground communications, be used, since it is impregnated with a fire-fighting compound that releases toxic fumes when dissolved.

The most commonly used is AI-95 gasoline. It is easier to obtain than solvent, and even if the family does not have a car, a small amount is often stored at home for household needs. To liquefy the foam, you need fuel without additives. In gasoline, the foam turns into a rather dense lump, more similar in consistency to taffy, and the excess liquid is drained off. It is difficult to apply such a substance in a thin layer, but with strong compression with a press or clamps, excess glue is driven out and removed. To prepare glue based on it, foam plastic does not need to be crushed; even large pieces dissolve quite quickly.

Solvent 646 allows you to create a more uniform and less thick mass. Although if the glue turns out to be too liquid, it will not be able to perform its main function - to hold it together. When choosing a 646 glue solvent, you need to pay attention to its composition. Made according to GOST - with a high acetone content - it will work perfectly, but on the market there are 646 from some manufacturers that do not dissolve foam at all.

Solvent 647 is very similar to 646 in its effect on foam, but it dissolves faster and the mass is more homogeneous.

If you need to prepare a completely liquid mixture (for a waterproofing coating), it is recommended to take xylene. With this solvent, the adhesive mixture can reach the consistency of liquid sour cream, ideal for application with a brush or roller over a large coverage area. With this composition, the base crumbles as finely as possible, but undissolved pieces of foam may still remain in the xylene. They simply need to be thrown aside when applying the substance to the surface to be coated.

Acetone is the leader among components in the speed of dissolution of foamed plastic into homogeneous glue. But it also has one drawback: acetone molecules evaporate too quickly, which is why gluing must be done quickly, before the mixture dries.

Useful: nefras (“Galosh”) does not dissolve foam, so it is impossible to prepare glue with it.

The transparency of the mixture after hardening will depend on the components, primarily on the foam. It is impossible to know in advance whether the glue will be transparent or cloudy, or whether it will be white or gray. If it matters, you can make a small amount of glue from exactly what will be used for the main mass and check what it becomes after drying.

How long can glue be stored without losing its properties?

Homemade foam glue is a perishable material that is best prepared immediately before gluing. This is explained by the high volatility of gasoline, xylene or acetone used for its production.

If you leave the foam in an open container, the solvent will soon evaporate and the composition will turn into a glassy mass. In a tightly closed bottle, this process takes a little longer, but still the quality of the standing glue will be significantly inferior to freshly prepared glue.

I hope the material presented is enough to properly prepare the glue on your own. The following video will help you understand the above.