Options for making a portable refrigerator

In fact, any refrigerator, no matter whether it is a home refrigerator or a more powerful industrial one, consists of a heat-insulating chamber in which a cold source is located. Therefore, to ensure reliable storage of products, two problems will need to be solved:

- Make a heat-insulated box or bag;

- Find a suitable source of cold.

The easiest way is to make a refrigerator with your own hands from polystyrene foam. Facing polystyrene foam has the best thermal insulation properties of all materials available at home. Any fabric, polyethylene, wood, paper, bulk heat insulators are at least two or even three times inferior to a refrigerator made of polystyrene foam.

Important! Almost any high-quality polystyrene foam is suitable for production, but the best option is a couple of sheets of a well-known brand of foamed polymer, which is approved for contact with food.

You can take ordinary foam plastic of the 20th or 25th grade, 30-40 mm thick, but after assembling the refrigerator, the inner surface will need to be covered with plastic film. This option is also suitable for adults; for children, especially if there is a predisposition to allergies, you will need to look for food-grade foam.

Manufacturing materials

Wood is considered the best material for making wine cabinets (except for conifers with a characteristic resinous odor). A wooden cabinet is a traditional storage unit that has long earned its impeccable reputation among collectors .

Wood allows wine to breathe and maintains the desired temperature and humidity. Wood species that are distinguished by their durability and excellent aesthetic characteristics are especially valued. Wood lends itself perfectly to self-repair and restoration.

The following breeds combine all these requirements:

- Red tree;

- cherry;

- oak;

- Karelian birch;

- acacia;

- nut;

- ash;

- maple.

Metal and plastic are used to produce high-tech wine refrigerators. Such equipment regulates and maintains the required parameters regardless of the temperature and humidity of the environment. Small models fit perfectly into home kitchens, and large refrigerators are installed in restaurants and cafes.

Clay is used to make drainage pipes, in which wine bottles remarkably preserve the properties of the drink. Tinted glass is often used for wine cabinet doors. Such glass prevents ultraviolet radiation from entering the cabinet, preventing oxidation of wine and sedimentation. In addition, tinted doors look impressive and decorate the wine cabinet.

Building a foam refrigerator

You can make the simplest version of a refrigerator from foam plastic with your own hands in the form of a plywood box, inside of which thermal insulation is made of polystyrene foam. In some cases, for example, for portable shoulder bags - refrigerators, heavy plywood lining is replaced with lightweight PVC plastic. How to make the outer cladding is not so important, the main thing is to assemble a high-quality and durable polystyrene foam box.

The procedure for making a portable thermobox from polystyrene foam comes down to the following operations:

- We cut out the foam sheet material to the size of the future refrigerator;

- We glue the polystyrene box together and line it with heat-reflecting material;

- We assemble a wooden box from plywood and place a heat-insulating foam casing inside the box.

If the refrigerated box is intended to be transported in the trunk of a car, it is necessary to reinforce the corner joints externally using an aluminum corner. As practice shows, during transportation, the wooden box of the refrigerator is often damaged at the outer corners and the seams come apart.

What could be more familiar than a refrigerator?

Back in the 30s of the last century, people prepared ice to keep food fresh.

The first refrigerators were large, expensive, and consumed a lot of electricity. For remote regions, even farms, it was unaffordable to have a refrigerator. Larry Hall, an American jack of all trades, came to the rescue. Its ammonia absorption refrigerator design only requires a heat source (oddly enough), which can be a fire, a gas or gasoline burner, or solar panels.

Such a refrigerator can be assembled in almost any workshop. The only moving part of this device is ammonia steam. A solution of ammonia and water is heated in a hot ball, the evaporating ammonia is collected in the cold part. As soon as the heating stops, ammonia condenses, taking away heat from the cold ball, and is forced back out.

Refrigerator body assembly

Cutting sheets for making thermal insulation from foam plastic usually does not present any particular difficulties. Even if you lack experience and skills, marking and laying down the four side walls, the bottom and the foam cover will not be difficult.

Advice! If you plan to build a refrigerator bag with your own hands from polystyrene foam, it is best to make the bottom from extruded polystyrene foam, for example, technoplex or a similar material.

An EPS bottom will be much stronger and more reliable than polystyrene foam, especially if the outer body of the refrigerator is planned to be made of plastic, or will be absent altogether.

To glue the heat-insulating foam body, you can use PVA and loose gauze fabric. Acrylic resins glue foam plastic worse; it is strictly not recommended to use the most durable polyurethane, bitumen or epoxy compounds; this is not the best option for products.

After gluing the polystyrene foam box, the surface inside and outside the refrigerator will need to be lined with isolon or other thin-sheet foil-coated polyethylene foam. As practice shows, various cladding options made from reflective films, paper or food foil are much more expensive and provide extremely low strength of the reflective surface.

Only after this can you take measurements to make a plywood box. If you already have at your disposal a plywood box with a lid of the required size, then you can do it much simpler - remove the internal dimensions of the future refrigerator, reduce it by 6 mm for the isolon sticker and cut out the heat-insulating box from polystyrene plastic according to the already known dimensions.

We glue a layer of foam plastic on the lid of the refrigerator so that the sheet of foam thermal insulation is completely immersed inside the box, and does not just cover the top plane. We attach the plywood cover to the piano furniture hinge using self-tapping screws.

Be sure to install a lock or latch that tightly presses the top cover and foam to the body.

Propane refrigerator device

The absorption principle of operation is the basis of refrigeration equipment that could run on propane.

Considering a gas refrigerator and the principle of its operation, it should be emphasized: in an absorption refrigerator, propane is assigned a modest function as a gas heater. The main components of the absorption process in the designs of household refrigerators are usually ammonia and water.

This is what the back wall of an absorption refrigerator looks like. This is one of those old models of devices that are suitable for modernization - conversion to gas fuel instead of electric energy

Ammonia acts as a refrigerant, and water acts as an absorbent substance.

The simplified gas model contains the following technological modules:

- Gas heating module.

- Generator (more precisely, a boiler).

- Capacitor.

- Absorber (absorber).

- Evaporator.

A gas heater heats the contents of the generator. The generator module is designed to produce ammonia vapor and supply a weak ammonia solution to the absorber area.

The condenser module is used to cool the ammonia vapor to the condensation temperature. A module called “absorber” functions as an ammonia absorber. The evaporator of a gas refrigerator serves as a cold generator.

Cooling element and bag

Often, a portable refrigerator not only has to be carried in a car, but also carried on the shoulder or in the hands; if you need to travel with such a load in public transport crowded with passengers, then a soft cooler bag would be a more preferable option. To do this, select a spacious bag made of polyester or durable canvas fabric.

For soft refrigerators, it is easier to replace foam walls with EPS sheets, and line the inner surface with isolon. In this case, the box of the refrigerator is glued together using durable construction tape to eliminate cold leaks through the foam joints; for a soft refrigerator, an outer cover with a foam cover with Velcro fastening is sewn from isolon. Even if you drop such a refrigerator, it will still remain intact and will serve for many years.

You will need several cold packs to get the job done. It is best to use ready-made industrial elements with a gel filler, but you can make your own. The bag is glued with polyurethane glue from several layers of polyethylene film and filled with a gel made from boiled salt water and a thickener. The bag is filled 60%, the air is removed, after which the filler hole is sealed with a hot iron. For a 10-liter thermal box you will need four half-liter bags, frozen in the freezer to minus 18-20 ° C.

Making your own - is it worth it?

A kitchen for dolls with furniture, dishes, food and many other items will cause a storm of delight in the little housewife. You can buy a doll set in a store, but it is much more useful and interesting to make it with your own hands , and always with your child. Here are some reasons in favor of this:

joint creativity brings children and parents closer, brings joy, helps to get to know each other better;- working on creating toys develops fine motor skills, imagination, and creative thinking;

- the number of items in a self-made doll kitchen can be much greater than in a store-bought one: it all depends on your desire and ingenuity;

- the child will learn to create things with his own hands and enjoy it;

- the craft will cost you much less than one bought in a store, and will bring no less joy to your daughter.

It has been noticed that children play with toys made by their parents or with their own hands with great pleasure.

Purchased car refrigerators

The modern market offers refrigerators in a wide range. A large number of manufacturers offer high-quality and functional products that meet all modern requirements for food storage.

Among the brands offered by thermal boxes are the following:

- Ezetil;

- Campingas;

- Mobicool;

- Mystery;

- Supra;

- Unicol;

- Osion.

The most sold and in demand refrigerators are Mystery, Ezetil and Mobicool.

They offer inexpensive, functional and reliable products that help maintain the freshness of food and prevent the catch from spoiling before the fisherman arrives home. Most of the listed refrigerators are produced in China. But this does not mean that the quality of the products is low. This country has long learned to make inexpensive equipment of decent quality. Some models are absolutely not inferior to famous European and American brands.

Conditions for long-term operation of a fishing refrigerator

In order for a fishing refrigerator to serve for a long time and with high quality, you will need to, if possible, fulfill several simple conditions. Connection to the device must be made in compliance with polarity (+ and -). So the car refrigerator will serve the fisherman for an unlimited number of years. In order to preserve the cold in the thermal chamber even more, I recommend putting 2-3 sealed isothermal cold accumulators inside (flat flasks measuring 10x20 cm, with filler from any manufacturer), you can purchase them in the same stores for a symbolic price of 150-200 rubles.

Kitchen set for doll

To make furniture and kitchen appliances, you will need cardboard boxes, so stock up on them in advance. Do not throw away cardboard boxes for shoes, juices, bulk products and other packaging. For upholstered furniture you will need scraps of fabric, synthetic padding, foam rubber or cotton wool. Prepare scissors, white and colored paper, cardboard, foil, glue, tape, paints, brushes.

Fridge

It's hard to imagine a kitchen without a refrigerator. The same, but miniature, will be in our kitchen for dolls, and will definitely be filled with tiny products.

Familiarization with the equipment design

Before you start creating a freezing installation, you should familiarize yourself with the operating principle and design. This will allow you to approach the solution of the issue consciously, and in the future you will be able to independently upgrade the created unit. So, refrigeration units consist of the following components:

- compressor;

- refrigeration chamber;

- capacitor;

- evaporator;

- thermostat;

- tubes.

As for the compressor, it is necessary to move the refrigerant through the pipes. But the evaporator is the place where the coolant turns into steam and evaporates. The set temperature level can be achieved thanks to the thermostat; it periodically turns the compressor on and off.

The condenser is a heat exchanger where steam is converted into a liquid state. Before you make a refrigerator with your own hands, you should know that modern models are also equipped with automatic regulation and control functions, dehumidifiers and filters.

DIY design alternative

The meaning of assembling a gas structure is also lost because there are practically no old factory structures of this kind in domestic use. Gas refrigeration equipment with an absorber (Russian production) is basically an industrial installation, large-sized, heavy, equipped with complex gas equipment.

An example of an industrial absorption gas plant. With relatively low gas consumption (in industrial terms), this absorption refrigerator shows high operating efficiency

Therefore, an alternative for homemade gas refrigeration equipment is considered more attractive. These are modern mobile compact cooling systems from a series of thermal containers and similar developments. Any of these systems covers the need for cold that burdens lovers of outdoor trips.

It is for the purpose of cooling and storing food in outdoor recreation conditions that people try to assemble gas refrigerators with their own hands. The range of modern mobile refrigeration equipment is huge

The price of the devices is quite reasonable. Most likely, buying, say, a Comfort will cost several times less than the cost of upgrading an old absorption system.

At the same time, in terms of technical characteristics, modern compact refrigeration equipment is actually comparable to the same parameters of Sadko . And the temperature range looks more attractive (up to -18ºС).

A more than successful alternative to homemade gas refrigerator designs. Convenient, mobile, compact Waeco-Dometic Combicool device, operating from three different heat sources

Finally, there is an opportunity to buy an imported industrial refrigerator that actually runs on propane. A good example is a universal device from a German manufacturer, produced under the brand name Waeco-Dometic Combicool .

The design of the mobile refrigerator ensures that cold is obtained when operating from one of three energy sources, including a gas cylinder.

Creating a freezing installation using a similar scheme: reviews from home craftsmen

According to home craftsmen, you can create an installation using the same principle, but using boxes of different sizes. The work will look like this: at the first stage it is necessary to install a frame, if there is none, then follows a layer of thermal insulation, which, according to the craftsmen, is mandatory. The chest must be lined from the inside; sealant should be used to seal holes and seams.

If there are quite a lot of products, the space can be supplemented with shelves, and then a cooling unit, doors and sensors can be installed. Consumers are advised to adjust the temperature until you can achieve the required system operating mode.

Depending on the size of the box, experts advise using cooling equipment, which can be borrowed from an old refrigerator. In order to ensure ease of movement, wheels can be screwed onto the bottom. If we are talking about a basement or cellar, then when creating a refrigerator for flowers with your own hands, you can only seal the cracks, install a split system and seal the doors. However, with this approach, you will only need to bring the external block to the surface.

Kitchen set for doll

For the manufacture of furniture and kitchen appliances

You will need cardboard boxes, so stock up on them in advance. Do not throw away cardboard boxes for shoes, juices, bulk products and other packaging. For upholstered furniture you will need scraps of fabric, synthetic padding, foam rubber or cotton wool. Prepare scissors, white and colored paper, cardboard, foil, glue, tape, paints, brushes.

Fridge

It's hard to imagine a kitchen without a refrigerator. The same, but miniature, will be in our kitchen for dolls, and will definitely be filled with tiny products.

Article on the topic: What is a thermoelectric refrigerator

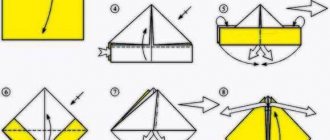

Step-by-step instructions on how to make a refrigerator out of paper:

If you figure out how to make a refrigerator for dolls with your own hands, then making kitchen cabinets and tables will not be difficult for you.

Microwave

To prepare food, Barbie needs a microwave or stove. It is easy to build a stove in the same way as a refrigerator, by gluing circles of colored cardboard and beads instead of handles to the box instead of burners.

Pencil sharpener

with a compartment for collecting chips - an almost finished microwave. It just needs to be given a finished look:

Now you can call Barbie and heat up dinner in the microwave.

How to make a gas refrigerator

A relatively simple way to manufacture a gas refrigerator, as already noted, is to use an exhausted absorption apparatus as the basis. To bring the same “Sadko” or “Morozko” model to “mind”, it is enough to exclude the electric heaters installed in the system from the design.

Instead of dismantled heating elements, it will be necessary to introduce gas heating by installing a heat exchanger and a propane burner in the structure.

The idea of gasifying an absorption apparatus previously operated by heating with an electric heater is theoretically feasible. This is what a direct connection to a gas burner looks like (+)

The model of the absorption refrigerator “Morozko” of the fourth edition of the ASh-30 series is well suited for creating a mobile device. The dimensions of the case of this design are 450*400*405 mm, weight no more than 15 kg.

The temperature of the freezer when the structure is operating at full capacity may well reach 10-12°C with a minus sign. It is not for nothing that the idea was born among skilled designers to remake the electric heating, replacing it with a propane heating pad.

However, the idea of a gas refrigerator is dubious, and there are a number of reasons to support this. Thus, the absorption process requires almost twice as much time to generate cold as a conventional compression refrigerator.

From an economic point of view, the design does not seem entirely rational, considering how much gas will be required to obtain 1°C sub-zero temperature for a home-made version. Nevertheless, design interest regarding the possibility of implementing the idea is quite high.

Step-by-step process for remaking “Sadko”

The electric heating elements of the Sadko refrigerator are located on the siphon tube. This structural element (siphon) is located at the bottom of the rear wall of the device. The siphon area is covered with a metal casing, under which there is a layer of heat insulator (mineral wool).

This shows the process of opening the protective metal panel on the back of an absorption refrigerator. As you can see, under the panel and the heat insulation layer there is an electric heater that needs to be removed

Initially, the amateur designer will need to perform the following steps:

- Place the refrigerator in a convenient place for work.

- Remove the protective cover on the rear wall.

- Remove thermal insulation material.

- Remove the heating elements from the siphon tube.

It should be borne in mind that do-it-yourself modifications here involve some risk. The absorption refrigerator system is filled with ammonia and hydrogen under pressure up to 2 atm. Careless dismantling of system parts and electric heaters can lead to depressurization of the system, which is hazardous to health. Caution must be exercised.

The next step for the amateur designer is to install a heating system that runs on propane. That is, it is necessary to mount a module in the area of the siphon tube that would carry out heating as a result of gas combustion. It is unacceptable to heat the tube with an open flame.

This means that a heat exchanger will need to be made. This could be, for example, a massive block of copper with a gas burner built inside.

Option for manufacturing heat exchange modules for internal placement of a gas burner. Such a module is attached tightly to the siphon tube of the refrigerator instead of a dismantled electric heater

The manufacture of a gas heating system necessarily involves the organization of a complex of protection against overheating. The operating temperature range for heating the siphon of the Sadko refrigerator is 50 - 175°C. Based on these values, you should consider a scheme for turning on and off the gas supply during heating.

For a circuit with electric heaters in absorption models, a refrigerator thermostat of the T-120 series is used. But this device regulates the operation of the heaters taking into account the temperature of the evaporator.

Gas burner flame regulator, which can be integrated into the design of a gas heating module. This is just one of several automation devices that will need to be equipped with a gas refrigerator (+)

A gas burner together with an automatic control device is a slightly different system. If a propane refrigerator is made with long-term use in mind, full-fledged automation will have to be made.

That is, for example, to control not only the heating temperature of the heat exchanger, but also to control the flame and monitor the gas pressure. We must not forget about the fuse system.

Homemade assembly examples

It was not possible to find examples of home-made designs of gas-powered absorption refrigerators that would be noted for long-term operation. There are only experimental options, often started but not completed.

There are also examples of assembly where a gas refrigerator was assembled with your own hands using a simplified method.

One of the successfully implemented homemade propane refrigerator designs. Similar “homemade” products can be found in sufficient quantities on the Internet.

In a simplified assembly version, a propane cylinder was used, the outlet of which was connected with a hose directly to a direct-action burner. The burner was fixed to the chassis of the absorption refrigerator, and the working nozzle was directed directly to the siphon tube.

The burner was ignited manually. Also, without any automation, using a purely “touch test” method, the heating temperature of the siphon was controlled.

The results are disappointing. During operation of the manual heating gas installation for 12 hours inside the freezer, the maximum temperature of the lower threshold was obtained - not lower than +3°C.

Thus, tests of a propane absorption refrigerator, made by hand using a simplified scheme, showed the extremely low efficiency of the gas apparatus. Moreover, judging by the gas consumption, this option for obtaining cold (Sadko-G) is unreasonably expensive.