If your finger is injured during a breakdown

The appearance of cuts on the fingers and blood after a knife breaks is of great importance for deciphering folk signs. The designation of superstitions concerns each finger individually:

- cut your little finger - you need to become more demanding of yourself and your needs. The sign indicates minor troubles, useless financial expenses;

- thumb - financial or moral assistance is required for relatives and friends. You may end up wasting too much money;

- indicative - you need to prepare for conflict situations with loved ones, problems at work;

- a cut on the nameless one is evidence of the emergence of gossip, slander and intrigue. Slander can seriously harm a person if there is a large amount of blood;

- break a knife and cut your middle finger - quarrels, disagreements with your loved one.

What does it mean to dream about a broken knife?

Any broken thing in a dream represents your shattered hopes and aspirations.

- A broken knife indicates imminent trouble; perhaps you will experience some kind of nervous shock due to the behavior of loved ones.

- If in a dream you were injured with a broken knife, then in real life you will face a long and serious illness.

- If the tip of a knife breaks off in a dream, then in reality you will experience a serious quarrel with your closest relatives.

If someone gives you a knife in a dream, then fate warns you about improper behavior with people around you. You are too pushy and aggressive, you need to learn a little tact and mercy.

Signs about a knife in everyday life - in the kitchen and on the table

Since people mostly “communicate” with knives while cooking or eating food, the most relevant folk signs remain superstitions relating to this area. Among them the most common:

- Eating from a knife means becoming angry (sharp tongue).

- Playing with a knife means conflicts in the house.

- The knife fell from the table - a man will soon come to the house. If the sound of the fall was loud and clearly distinguishable, then the guest is someone familiar.

- The knife not only fell, but also stuck its tip into the floor - leading to a serious quarrel. If this happened during the process of slicing bread, then he would be dead.

- The knife fell with its blade in the direction of the person who dropped it - to an unpleasant conversation.

- Pointing a knife at someone means provoking illness in a person.

- Cutting bread with not one, but two different knives means misunderstanding in the family.

- Leaving a knife stuck in bread on the table means financial problems and hunger.

- Not removing the knife from the table at night means inviting trouble for yourself. Basically they say that the brownie will cut himself, get offended and begin to harm his careless owners. But there is also a version that evil spirits will play with a forgotten knife, and the devil will be able to stab the owner of the house with it.

- Putting knives crossed on the table means trouble. Crossing a knife with a fork or spoon means death.

- Sharpening a knife for a pregnant woman means harming the unborn child.

- Holding a knife in your hand and cursing it means offending the product and incurring its wrath. Don't be surprised by sudden cuts - this is a kind of revenge.

The knife should be taken seriously, as it easily catches and conveys negativity. But if they are “friendly” with the product, then, on the contrary, it will help the owner and protect him from troubles.

Types of handle materials used

To choose the right material for the handle, you need to know the purpose of the knife. Of course, the shape of the shank plays an important role. When making a knife for yourself, you won’t have many questions. When producing a blade to order, the matter takes on a different character.

It happens that the customer makes a choice in favor of a material that is not entirely suitable for the purpose of the blade. It is necessary to explain what is what and find a compromise. Have the customer read a couple of articles about handle materials. Sometimes it's really difficult to make a choice.

There are a lot of materials both in properties and characteristics. Let's try to figure it out and perhaps advise you in choosing raw materials.

Birch bark

A striking example of the use of natural materials. The birch bark handle has a velvety texture. This property gives a pleasant feeling when holding the blade. This product has a lot of advantages:

- low thermal conductivity will warm your hand in winter and keep cool in summer;

- Rotting of the material is not dangerous, it is due to the presence of a natural antioxidant - tar;

- good water-repellent properties;

- such a knife will not sink in a pond, it will float like a float, thanks to the porous structure of the raw material;

- high durability of the material.

Set on the handle is carried out in parts. Birch bark is cut into pieces, brewed and then collected into a handle. You can do without soaking; the pieces are glued with glue and secured with a pommel. After the inlaid handle has dried, it is processed to the desired shape with a file or on abrasive wheels.

Birch bark handles.

Plastic

Compared to wood, plastic has appeared relatively recently. About 100 years ago. At the dawn of the processing of this material, the industry was not yet developed as it is today. At that time, this material was considered rare and was not used for handles.

Closer to our time it has become more accessible. And today it is often used to make knife handles. There are different types of plastic:

- ABS plastic . The simplest version of the material, it is used for kitchen products;

- nylon thermoplastics . They make products that are quite light in weight; the hand does not get tired of working with them;

- elastic thermoplastics . They do not like high temperatures and have low mechanical strength. The material is not used very widely;

- micarta . Due to its qualities, it is in high demand. It belongs to the group of electrical insulating laminated plastics. Impact-resistant and easily processed material.

Expert opinion

Konstantin

Since childhood, I have been interested in knives and everything connected with them. I bring the accumulated knowledge to the masses. I make knives myself. I take criticism positively, but I also like to argue.

Today there are plenty of plastic materials for making handles. There are raw materials that surpass many natural materials in their characteristics. And accessibility plays an important role.

Examples of plastic handles.

Rubber plastics

Convenient and inexpensive material, quite simple manufacturing method. Stacked or combined handles are made with it. If you need to make a whole handle from raw materials, then it is made by simply gluing two halves on the shank.

Good grip on the hand is the main advantage of the material.

It is also an excellent dielectric, it can be used in any weather, and does not absorb moisture or odors. For a normal handle, all the positive characteristics are present. But the material is highly flammable, and if it is heated to the point of burning, it will not be possible to extinguish it.

Handles made of rubber plastic.

Bone

Bone knife handles are durable and beautiful in appearance. They do not absorb foreign odors and are moisture resistant. The materials used are: tusks, horns, shells and skeletal bones of animals. But they have several disadvantages:

- high probability of cracking;

- scratches quickly, excessive softness;

- after contact with blood or fat, it becomes very slippery;

- The weight of the product is not small, you won’t be able to work with a knife for a long time.

The structure of a deer or elk antler resembles the bark of a tree. The material is considered quite popular. It does not require special care; light sanding of the surface is sufficient. The material itself is considered a decoration for the knife.

The installation of the handle is used with there material, both mounted and overhead. The horns of domestic animals are often used for these purposes. By choosing natural tusks and bones for work, you can make a beautiful figured product. Various images are also cut out on them.

Bone handles.

Metal

This raw material is used for the handles of kitchen knives, folding knives and multitools. The manufacturing principle is quite different. Kitchen knives use hollow metal handles; they are simply welded to the blade. And in some knives, the handle may be the tang itself.

For better holding in the hand, they are made corrugated. But you won’t be able to work with such a handle in the cold for long. Strong thermal conductivity will heat the handle. Also, such a product weighs quite a bit, which negatively affects the work process.

Metal handles.

Acrylic

Acrylic handles are easy to manufacture, have a wide range of colors, and are easy to use. Stores sell acrylic bars from which you can make a handle of any color. It is also easy to install the mounting type or overhead.

You can make an acrylic blank yourself. At the beginning, a template of the future pen is made; it should repeat its shape and size.

You will need to make two such templates. The handle is designed for surface mounting. Then epoxy resin and acrylic glue are mixed in equal proportions. Next, the mixture is poured into the blanks and left for 48 hours to dry completely. You can add dye to the mixture. Then you will get a handle with original patterns.

Acrylic product.

Tree

Wood is considered the most popular and diverse material. Non-slip and attractive appearance are the main components of the material. The handle can be made of any type: anatomical or another shape. But different tree species have a variety of colors and qualities, let's look at them:

- Ebony, ironwood and boxwood are very popular. It is better to treat handles made of these materials with moisture-protective agents. They do not resist moisture well;

- African bubinga tree, has a beautiful natural pattern and is resistant to any weather conditions;

- wenge wood is characterized by good workability and a beautiful cut;

- bokote wood is wear-resistant and porous, but it is very expensive;

- The thuja tree has excellent natural qualities; it has high resistance to moisture;

- walnut is not widely popular due to slight deformation;

- our fellow countryman maple has small pores and high moisture resistance;

- burl wood is the most reliable natural material; it is difficult to process due to the random structure of the fibers.

Wooden handles.

Leather

The leather handle does not slip in the hand, but that’s where its advantages end. Unfortunately, it quickly accumulates moisture and absorbs odors. Rough and thick leather is used for production. The handle is of a typesetting type. Pieces of leather are put on the shank.

They are glued together and pulled together at the top at the end of the shank. Next, the excess is ground off on an abrasive machine, and a comfortable handle is obtained. The popularity of raw materials is not great; many liquids are harmful to the skin, especially saline solutions.

Examples of leather handles.

Synthetic fibers

In conclusion of the description of materials, synthetic fiber should be mentioned. Application is found in this way, already on top of the existing handle. The principle is to simply wrap the product. The material is highly resistant to aggressive environments.

And the winding is easy to change. The most famous such raw material is textolite.

It does not absorb moisture and is not affected by ultraviolet radiation. During the working process, the product does not slip in your hand. The only drawback is the aesthetic component of such material. But the level of practicality is maximum.

How and where to throw it away

In ancient times, a person’s life often depended on the strength of a knife. Therefore, the sacred object was treated with special care.

If a knife breaks in your hands, then you should not store it in the house, but rather, according to signs, bury it under the threshold. If you live in a comfortable apartment, then bury it in the yard in the roots of any large tree. At the same time, mentally repeat: “Even though my knife is broken, it will not bring any harm to me or my loved ones.” In this case, the debris will become a reliable protection against the negativity of others.

The working process

The dimensions of the manufactured handle depend on the dimensions of the knife shank. In this case, the thickness of the linings should not be less than 6-7 mm. Otherwise, such a handle will simply be inconvenient. So, we take our wooden beam and make two blanks for the overlays from it.

Now we take the prepared rod and, using pliers, separate the pins from it along a length slightly exceeding the total thickness of the knife handle. Their ends must be rounded for ease of installation and safety.

We take a knife, apply the shank to the workpiece and outline the front contour, as well as the place to drill the hole. After this, drilling should be done according to the marks, followed by processing of the linings on the side of the blade. If you do not do this now, then doing such work in the future will become extremely problematic. This stage ends with checking the conformity of the pin to the workpiece.

We take the prepared veneer and cut it. We do this along the contour. We place a piece of veneer between the overlays. All excess is removed using a carpet knife. Once this is done, you can apply epoxy to the outside of the trims. In this case, the pin should already be installed by this time. We glue the veneer and make sure there is no displacement. Having attached both pads, we carefully place the entire structure in a vice.

If there is no desire or opportunity to replace/repair a knife that has become unusable from a craftsman, but they need to be worked on, our advice will help. With their help, it will be possible to repair the handle and correct the blade itself.

The blade broke

Why does a knife break near the blade? It's not very often that an incident like this happens. But in some cases, having manifested itself once, it can even be repeated. How to find out why knives break in the house with such frightening consistency?

A blade cut in half is a sign of causing damage to the house and residents. Higher powers are trying to protect the owner of the item. The knife, in turn, absorbs most of the negativity, and even all the bad things that are sent to the owner. If you do not take the necessary actions, trouble may soon come.

Rusty spots on the blade are also considered to be a sign of damage caused to one of the owners of this item.

Which part is broken

When a knife breaks, the omen has a negative meaning in all cases of the incident. You can specify in which area problems will arise based on the damaged part, time of breakdown, additional nuances (cut on the hand, fingers, appearance of blood). The general interpretation of the sign when a knife breaks in your hand is a loss of vitality, energy, and health. But decoding can only be done if the quality of the product is good.

Additionally, it is worth considering the moment when the knife broke in your hands. The sign has nothing to do with it if new sharp, piercing household items appear in the house. This is how an old knife shows resentment towards its owner.

Knife tip

The moment when the tip of the knife breaks is dangerous. Especially if this happened during the cutting process. It is difficult to find the point in a mass of chopped vegetables and fruits. Popular superstitions interpret this nuisance as the presence of bad energy in a person, in the house. It is quite possible that a black influence was directed at the one who performed the actions with the knife. The knife, in turn, as a talisman tried to neutralize the damage, the curse. Breakage indicates that the negative impact is great, which is why the knife could not withstand the pressure.

Lever

The most harmless interpretation of a folk sign is if only an element of the knife breaks in your hands - the handle. It is easy to fix, but it must be done immediately, without delay. Otherwise, this will become a harbinger of quarrels with close relatives and loved ones. The reason for the disagreement will be:

- misunderstanding;

- harmless jokes;

- the desire of a loved one to be alone.

There is no serious threat to life if the knife handle breaks. There is no need to throw away the knife. But it’s worth becoming more attentive to your family and friends.

Handle attachment methods

It is not for nothing that the handle is considered no less important than the blade. You can go out of your way to make the best blade in the world. But without giving him a decent hand, we can assume that all the work is in vain. The further fate of the product depends on the method of installation and the material of the handle.

The ease of use of the product depends on the part of the knife that the hand holds. And this is a very important and responsible moment. Knife cutting and hand fatigue directly depend on the shape of the handle. There are two types of handle mounting.

Surface mounting

Overhead mounting of the handle.

A more complex method and a labor-intensive handle made of linings. At the beginning of creating a knife, it is necessary to decide on the installation of the handle. In this case, the shank will be a continuation of the blade.

Using any material: plastic, wood, synthetic polymers and other materials, you can make overlays.

To do this, two identical plates are cut from the necessary raw materials, which will be attached to the shank using rivets. The exception is folding knives. There the linings are glued or attached to dismountable bolts.

According to experts, this type of handle installation is more reliable. But it should be borne in mind that the weight of the entire product will increase. At the stage of creating the blade, the master should already have an idea of what the handle will be like. The tang should be a full continuation of the blade, even possibly with anatomical notches.

Briefly, the installation process is as follows:

- Make a sketch of the handle, this will only help in the future.

- We adjust the linings to the shank and straighten them if necessary.

- We cut out two identical plates from the required material.

- We mark the shank and pads for the holes. We drill them.

- All this is held together with rivets.

- Finally, we finish the handle with sandpaper and sand it with a felt wheel.

Installation diagram of the overhead handle.

Mounting

Mounted handle mounting.

The process takes less time and is simpler in nature of manipulation. The principle of mounting is to insert the shank of the blade into the hole in the handle. Similar to how a file is mounted into a handle. If it was structurally intended that the shank be of short length, then the method is just right.

Planting will be done using glue or epoxy resin. Also, the shank can be quite long.

In this case, a thread is cut at the end, and the handle is secured with it. You can also use a typesetting version of the handle.

This installation method has its advantages: light weight, giving the handle any shape, and repairs can be made. When choosing a mounted installation, you will need a certain tool. This list is not long, and the main thing is that a good business executive can find a lot of it.

Brief instructions for mounting the handle using the mounted method:

- The tool set is small: file, needle file, drill bits, drill, pencil, ruler, sandpaper, epoxy glue. This toolkit will be sufficient.

- We make a sketch of the future handle. Place the blade on the paper and outline approximately what you should get. You can indicate the dimensions of the workpiece.

- We select a piece of material from which the handle will consist. It should be brought to symmetry. And only then do the markings. We fix the future handle in a vice and begin drilling holes with a thin drill.

- In the process we try on the shank. When you achieve a good, stable position, you can say that half the work is done. Then we process the handle taking into account the holder and bolster. And you can start gluing. Epoxy resin is ideal for this. It dries quickly and that's the main thing. We set it to compress under pressure. You can make your own so-called vice from wooden plates, pins and wings.

In fact, there is nothing complicated here. Do everything according to your sketch. When the handle is glued to the shank, you can bring it to the required condition using files and sandpaper. An even simpler option is with a long shank with a thread at the end, where a nut is screwed on and pushed into the handle. This type of mounting is most preferable.

Mounting diagram of the handle.

Why break a knife in a dream: a sign about the destruction of plans

Breaking a knife in a dream is a sign of failed plans. Something will not go as planned, and you will have to give up your dream. Cutting yourself with a knife in a dream means a nervous breakdown in reality. It’s good if you managed to repair a knife in your dream - this means that you will be able to emerge victorious from any life challenges with honor.

If you dreamed that a broken knife was lying on the table, get ready for unexpected expenses.

Seeing that a knife breaks in the hands of another person means the collapse of your plans and hopes. It is necessary to develop some other plan on how to achieve the goal.

If you saw a rusty knife in a dream, you will quarrel with your “other half.”

If you see only one handle without a blade, there is a danger of being robbed.

In many cases, a dream with a broken knife warns of impending troubles and even life-threatening dangers. It is necessary to exercise caution and prudence.

Repairing or changing the handle

Handles are divided into two main types - overhead and mounted. Before working with the handle, wrap the blade tightly with something to avoid injury; To do this, you can use tape, electrical tape or a strip of fabric, the ends of which are secured with thread or glue.

Inserting pins

Most often, handle play occurs when the pins and rivets that secure it to the shank become loose or fall out completely. In this case, the repair is done as follows:

- both plates that make up the handle are removed;

- their internal surfaces, as well as the surface of the shank, are cleaned of glue and adjusted together with a file or emery to eliminate both backlash and gaps when mating with each other;

- the parts are lubricated with new two-component glue and tightly applied to each other;

- pins are inserted;

- the resulting assembly is securely fixed with clamps or in a vice and left until completely dry, after which the protruding ends of the pins are cut off and ground.

This is important: while the glue is drying, you should not apply too much force to the assembly (for example, placing the handle under a press). The assembly may “float” under excessive load and lock in the wrong position in relation to the pins that have not yet been cut. The finished product will be unusable after repair.

Changing the handle on a knife with a mounted mount is done in the same way, but instead of the old handle, a new one is taken. In the Japanese tradition, the shank is generally made in such a way that even at home, an old handle from a magnolia chef’s knife can be knocked off and a new one can be put on, which is sold as a consumable. In the budget segment, for the manufacture of handles, for the most part, not the most suitable types of wood are used, including those with defects; To hide the defectiveness of the material, a thick layer of paint and varnish is placed on the handle, which makes it slippery and uncomfortable. Replacing such a handle is forced and can radically improve not only the appearance of the knife, but also the safety of working with it.

Helpful advice: instead of varnishing, a wooden handle can be protected from rotting and damage by regularly oiling it with natural compounds, such as clove or boiled linseed oil.

If the knife has a slippery handle and there is no stop (guard or developed bolster), you can drill a hole at the end of the handle, thread a lanyard cord into it and put the resulting loop on your wrist - it will prevent your hand from slipping onto the blade and getting injured.

If you make a guard yourself, check with the current legislation so as not to accidentally modify an ordinary knife to the point that it would qualify as a bladed weapon.

The knife does not have to be repaired if it is purchased from a reliable seller, and it is used only for its intended purpose. You can learn about how to use knives correctly, how to store and care for them in other articles on our blog.

Sometimes the handle linings of knives break off, especially if they are made of plastic. It’s a pity to throw away a knife plate, especially when the blade can still serve for a long time. First, we will discuss two ideas for restoring a knife handle, and then we will try to make one of them a reality. Any person holding cutting tools, a hammer, pliers and a brush can handle this type of work.

If the shank is thick enough, then you can take a piece of hard wood, make a cut in it or drill a hole and insert the shank into it with tension. This type of fastening of the handle to the shank is called mounted. With a thin shank, this method of securing the handle will not be very reliable. For such a case, it is better to make the handle from two identical halves and secure them to the shank with rivets, pins or furniture ties. This method, called riveted or overhead, seems to be the best here. We prepare the knife for restoration by completely removing all remnants of the previous handle from the shank, and putting it in order.

Folk signs if a knife breaks

More precisely, the breakdown of a knife can be interpreted as follows:

- If the device breaks in your hands, it means that the health and well-being of loved ones is at risk. This could be a car accident, attempted robbery, or fire.

- Very often the blade breaks due to damage. Being the spiritual protector of its owner, the knife in such cases takes the brunt of the blow and thereby averts trouble from the person.

- Sometimes the breakdown of an old blade after purchasing a new one is interpreted as an offense against the owner.

- A device that breaks after falling on the floor often promises a break in a romantic relationship or an unexpected separation. Serious quarrels with close friends or family members are also possible.

You cannot ignore the signs of fate even if the knife breaks in a dream. Depending on the situation and details of what happened, the following interpretations of the signs can be distinguished:

- Getting stabbed in a dream with a blade broken in the middle most often means a serious illness that can overtake a person in the near future. In addition, such a dream can warn of an already existing, hidden disease.

- Seeing a broken knife lying on the table means losses.

- If in a dream someone breaks a device in front of the beholder, it means that events occurring in life may end badly, even despite the imminence of success. In this case, it is better to take a break and postpone far-reaching plans for a while.

- If you manage to fix a broken knife in a dream, this may mean a quick reconciliation with a loved one.

Sign if the tip of the knife is broken

If the tip of the blade breaks, then this most likely means strong envy on the part of people close to the family circle. It is even likely that they tried to damage the house.

In the event of such a breakdown, there is no need to throw away the device - you can take it to a workshop, where it will be given a new shape.

Sign if the knife breaks in half

A device broken in the middle promises serious health problems for family members and close friends. There is also a high probability that relationships with colleagues may suddenly deteriorate at work. Sometimes this happens due to an unfair slander from a person who was previously considered a friend.

Sign if the handle is broken

Although a broken handle means trouble, of all the signs associated with a knife, this is one of the most harmless. If the handle of the device breaks in your hands, minor family quarrels or a short-lived spat in a romantic relationship are possible. It could also mean that the person will have a minor disagreement with one of their close friends.

Advice! Unlike a broken blade, the handle is easy to repair, but it is important to do it as quickly as possible.

So the consequences of the sign may not affect the life of the owner of the device at all.

A sign if you are injured by a broken sheath

A broken knife can easily cut you. Depending on which finger was damaged by such a blade, a number of signs are distinguished:

- A cut on the right thumb promises trouble for loved ones, but the one who cut himself will solve the problem. A cut on your left finger could mean future financial problems.

- Cutting the left index finger means a quarrel with your best friend, the right one means disagreements at work.

- If you cut the middle finger of your left hand, then there is a high probability of a major quarrel with your closest relatives. An injury on the right hand is a warning of imminent betrayal or betrayal.

- A cut on the ring finger means the person will soon be slandered.

- Damaging your little finger means minor problems in everyday life.

You can learn more about the signs associated with a broken knife from the video:

Types of blade defects and methods for eliminating them

Chips and deformations on the cutting edge

The most common type of damage is chipping or deformation of the cutting edge. They should not be confused with blunting: in this case, the line formed at the place where the leads meet simply ceases to be imaginary and forms an additional plane that glares in the light; chips are uneven damage to this very line of convergence. If you turn the knife towards you with the side where the cutting edge is located, or look carefully at the blade from the side, the chipping will be visible. These are the chips. In case of deformation, on the contrary, the cutting edge retains its integrity, but “goes in a wave” - it bends in different directions, preventing a comfortable cut.

How do we fix it? To do this, we completely remove the metal to the place where the descents end and the approaches begin. If the blade has a profile without leads, we grind it down to the place where the deepest chip ends or where the deformation of the cutting edge began. We should get a flat additional surface, from which we will have to “extract” the updated cutting edge. This is done in three stages: first, the blade is rough sharpened to determine where and how much metal needs to be removed from the slopes, then the slopes are ground on both sides (that is, the supply is leveled - it is made equal in thickness along the entire length of the blade), and then the final fine-tuning

Broken off point

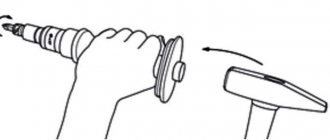

If the very tip of the blade is broken off, it’s okay; the repair is done almost identically to the previous case. First, the blade is ground down, giving it the required shape, then it is sharpened, forming new slopes, and only then the cutting edge is brought out at the desired angle. An option for the lazy is to grind off some metal from the butt and create a new point just below the location of the old one.

Scratches and chips on the holomen (side surfaces of the blade)

This and the next type of damage are the most difficult to eliminate. Usually the blade has sufficient hardness to withstand household mechanical damage, that is, the risk of scratching it on something is unlikely. Most often, blades are scratched during careless sharpening, when it is not the leads or the lower part of the bevels that are applied to the sharpening stone, if there are no leads, but the entire blade flat.

Shallow damage can be removed using a grinding wheel or sandpaper placed on a flat surface, for example on glass (ordinary GOI paste on a polishing wheel is unlikely to cope with them). If the steel is hardened, this will be very difficult to do. After all, in addition to removing a deep scratch, you will also have to smooth out the hole left on the surface of the blade from it.

Blade curvature

This is often another complex type of damage - an “unhealthy” bend occurs when something heavy is pryed with a knife. Even if we perform the exact reverse action, we will either get an additional bend or even break the blade (for example, if the steel is hardened to high hardness units, that is, one that does not bend, but simply breaks under lateral load).

If the blade is flexible, it should be clamped in a vice through wooden spacers and carefully straightened with your hands, observing safety precautions, and always wearing gloves (preferably chain mail or specially designed to protect against cuts). When the blade acquires a shape close to its original one, it can be placed on a flat surface and tapped with the narrow side of a hammer, removing any remaining deformations and finally leveling it.

What do the circumstances mean?

Intensification of negative interpretations occurs under certain circumstances. It is especially important to protect family members when a second or third broken knife appears. According to popular observations, knives often break or disappear in families that are influenced by black magic.

Strengthening of values occurs if:

- The blade is covered with rust and small cracks

. Indicates serious health problems, loss of vitality and spiritual strength; - The handle broke in my hands while cutting

. Evidence of confrontation between family members; - for no reason the knife breaks in half when cutting meat dishes, meat and sausages.

Warning about imminent problems with a large loss of money: accident, surgical intervention, robbery; - break the tip and not notice it.

As a result, the broken piece remained in the dish - an indication of the need to keep your mouth shut. Caution will save you from troubles, slander and problems at work.

The tip of the knife broke off, can you give me some advice on how to fix it?

Hello everyone! A little background: I have long wanted to buy knives for the kitchen, because... I love to cook and the ultimate dream of mine was a wusthof or zwilling set, about 200 dollars, but I came across this forum quite by accident and ended up spending a little more than $200 first on knives, then it turned out that they don’t cut on simple boards, and even with They don’t want to use the rest of the knives, so give them a magnetic holder. And at the moment we have Misono 440 Gyuto 210mm (this was the first and apparently not the most successful purchase), Deba 180mm Ichimonji Kichikuni and GINGA Swedish Stainless Petty Knife 150mm. So far I'm happy. And so to the crux of the matter, I cut up the fish and went to wash the knife, but it slipped out of my hands and, hitting the shell, broke off the tip, it broke off quite a bit, but it was unpleasant. As I understand it, you need to grind off the butt a little without touching the cutting edge, but I don’t know what to grind it with, not with a file. Please enlighten me on this point, I don’t understand how to attach a photo yet, but I’ll post it right away when I figure it out. PS sorry for so many bugs.

Gorga60

Please enlighten me on this point, I don’t understand how to attach a photo yet, as soon as I understand I’ll post it right away

Take an ordinary Soviet diamond stone, smaller in size, and slowly, without pressing, remove the excess from the butt