For a long time, the grinder served you faithfully. How much metal has been cut over the years of service! Now the instrument is becoming unusable - a piece has broken off, the buttons are stuck, everything is loose. You have to buy a new one, but it’s a shame to throw away good material. We will tell you in this article what you can use the engine and gearbox of an old tool for.

Engraver

A home craftsman sometimes has problems with surface treatment that is impossible to approach with universal equipment. The part may turn out to be fragile and impossible to clamp, or bulky. It needs to be modified on site. From an old grinder you can make a tool for processing small surfaces with a flexible shaft. The result will be an analogue of a drill.

Materials required for manufacturing:

- flexible shaft, which is purchased or selected from stock;

- working tool holder;

- a pair of bearings with spherical rollers with a diameter of 22*8 mm;

- working tool for processing with a shank diameter of 1-3.5 mm.

The presence of a flexible shaft will expand the functionality of the tool. With its help you will be able to get into the most hidden corners of the part and reduce the load on your hands.

It is possible to use many of the master’s home supplies as tools:

- Drill. With its help, the tool will turn into a small drill or drill.

- Milling cutter. Using the design of cutters, you can process flat models, recesses of different shapes and depths.

- Cutting discs for processing thin materials.

- Metal and felt brushes for grinding and polishing surfaces.

- Abrasive tool with heads of various shapes.

- Tool for writing inscriptions.

Cutters can be made from broken drills, sharpened at the desired angle.

Nozzle manufacturing process

First of all, let’s take and cut off the rod where the bearing is located from the burnt anchor of the angle grinder. We don't need all this in the future. It is best to cut the anchor using the same angle grinder, but you need to secure it firmly in a vice so that it does not fly out.

Then you will need to get rid of the gear and burn out all the wire on the anchor. We also don't need wire. To burn out the wire, and not have to worry about unwinding it manually, we will use a small gas burner.

As a result of all the above manipulations, we should have a clean armature blank in front of us, without wire, bearings and gears. It will be necessary to work a little more and sand the surface of the anchor with fine-grained sandpaper.

Sander

Converting a broken grinder into a grinding or polishing machine is not difficult. You can adjust the number of revolutions using a dimmer (lighting regulator) if the power of the tool is low. Otherwise, a laboratory autotransformer is used to regulate the voltage.

A grinder with a diameter of 125 mm can be converted by removing the protection and fastening nut. A support plate with Velcro is installed in their place. Such a tool is sold in any tool store. A grinding disc of a suitable configuration is attached to it. The discs on the other side have a felt lining. Thus, the new tool will be able to sand wooden boards and bars. A felt surface, in the presence of an abrasive paste, is used to polish car headlights and bodies. It is better not to use a tool with a power of less than 1 kW in professional activities . Grinding gives a greater load than trimming, so low-power machines can literally burn out at work.

Handy homemade products from an angle grinder for workshops

zen.yandex.ru From angle grinders, craftsmen make various devices that expand the functionality of the angle grinder and simplify the work. And making them is not difficult at all.

Photo: topreviewzone.com

Stand for grinder

Useful when you need to make many different sections. The simplest option is to weld two guides from a rectangular pipe to a metal base. Make a handle from the same pipe to which to attach the grinder. On the base you can make a guide from a corner for cutting workpieces at a certain angle.

Photo: AVTO CLASS (youtube.com) Some craftsmen make similar racks from blocks and plywood. The design is simple and reliable.

Photo: Gökmen ALTUNTAŞ (youtube.com)

Grinding device

Can be used for removing rust, removing paint from walls, polishing, etc. The advantage of this homemade product is that the surface is always processed at the same angle and with the same force, without leaving any indentations.

Photo: mistrymaketool.com

A circular saw

A simple device for even cutting of wood and sheet metal. For wood, specialized saw blades with three teeth are used (do not install blades from a regular circular saw).

Photo: Home Craftsman (youtube.com)

Compass for cutting circles

It is made of a metal plate and a pin, which is attached to a hole in the center of the circle.

Photo: glavmex.ru (youtube.com)

Belt grinder

The movement of the tape is given by a wooden cylinder, inside of which a nut is glued for installation on the angle grinder shaft. The device itself consists of two square pipes of different sizes. A spring is inserted inside the larger pipe, with the help of which the tape is tensioned.

Photo: Mistry MakeTool (youtube.com)

Grinder

The angle grinder is attached to the wooden base with a bolt, the rear part is installed in a mount made of a block, and can additionally be secured with a clamp. Used for sharpening tools and grinding various surfaces.

boat motor

If you are an avid fisherman with a PVC boat and have only used oars until now, you should think about making an inexpensive propulsion unit. Gasoline engines are expensive, consume a lot of resources, and make a lot of noise. They are good for fast and long hikes. If you need to go out into the middle of the lake or check supplies, you can get by with consumables from an angle grinder. For a non-working tool, you will need an angular gearbox.

To mount the engine, we make a transom from plywood, a hinge, and 20*20 mm pipes. You will also need a pipe to attach the leg, screw and attachments. The screw, with low engine power, is cut out of 4 mm steel and bent. For the propeller you will need a battery and a 12 V motor. The battery capacity is calculated depending on the engine power and operating time. It is better to take a spare battery.

Self-refinement to a cutting machine

The simplest homemade machine is a machine made from a small angle grinder. The work will be accompanied by a minimum of costs, and manipulations will take a few hours. The exit structure will be a long metal pipe that serves as a handle and frame.

A metal transverse strip with two holes for fastening the tool is welded to one of the ends. On the same side, the pipe is fixed to a piece of angle on a movable shaft. The first one can be fixed to the desktop or to the floor in the workroom. If you are faced with the question of what can be made from an angle grinder, you can use a cutting machine using the described algorithm. According to it, on the opposite side of the fastening it is necessary to fix a spring, which will ensure the return of the structure to its original position. After completing this stage, you can use your homemade product. You just need to install the device correctly.

This version of the machine is the simplest solution for metal processing, while complex work will require precision, so the design for solving such problems must be made more stable, which means the work will have to be approached more thoroughly.

Motorized bicycle

Making a self-propelled bicycle is easier than it seems. You don't even have to disassemble the grinder. You will need an inverter from 12V to 220V, lithium batteries, and a button with a power regulator. The essence of the mover:

- The shaft will transmit torque directly to the tire. For this purpose, a bushing is made with roughness for better engagement.

- We attach the machine to the frame.

- To press the bushing, we use a cable similar to a brake handle. This will make it possible to turn on the engine not constantly, but to use it as an auxiliary one.

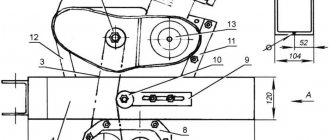

Manufacturing a machine with a frame

You can also make a cutting machine from a grinder To do this, you should prepare the following tools and materials:

- profile pipe;

- steel corner;

- Metal sheet;

- welding machine;

- drill;

- channel;

- bearings;

- shaft;

- pipe;

- spring;

- relay pedal.

READ Make your own plow for a walk-behind tractor

If desired, the sheet of metal that goes on the platform can be replaced with chipboard. The stove will be an easier option. There must be several bearings, they must be the same. If you think about it, welding can be replaced with strong bolts, which is what you need a drill for. This option will allow you to disassemble the machine if necessary.

For a screwdriver

The screwdriver used by the author of the following video already has to work under extreme loads when cutting threads on M8. The use of a reduction gear from an angle grinder increases the amount of torque and allows you to cut threads in more comfortable conditions. Here we use a burnt grinder , where the rotor is cut to a length that at the same time allows us to securely fasten the end of the cut shaft in the screwdriver chuck and fit the plastic body of the grinder tightly onto it. For a more thorough connection, the screwdriver is attached to the body of the angle grinder with fasteners, while the gearbox bearing of the angle grinder fits into its seat. Drilling and cutting threads with tooling prepared for such work does not require any additional effort.

Here's what you can make from a windshield wiper motor and an angle grinder gearbox!

Sliding gate drive

The following video shows one of the options for driving sliding gates based on a gearbox from a burnt angle grinder and an old screwdriver. The drive is equipped with an automatic device for controlling the opening/closing of the gate. The chain drive with a drive sprocket on the gearbox spindle operates at high speeds to perform the gate control function, therefore creating increased noise during operation.

Drilling machine from an engine from a washing machine and a gearbox from an angle grinder

Materials and tools used by the creator:

List of materials: - motor from a washing machine 650W / 1350 rpm; - gearbox from a 180 angle grinder; - corner; - round pipes; - sheet steel; - bolts and nuts; - springs; - switch; - cable with good insulation.

Drilling machine production process:

Step 1. Refinement of the gearbox A gearbox

from an angle grinder by 180, it lowers the engine speed more than

the gearbox

from a 125 angle grinder, as a result, we get higher torque, and the axle in such a gearbox is thicker. The creator, using a grinder, cuts off a piece of the anchor and knocks the remains of the anchor off the axis. It will also be useful to cut off a piece from the body of the angle grinder in order to screw this part with a seat for the bearing to the gearbox. If there is no such part, you can weld it yourself from sheet steel, using a piece of pipe as a clip.

Step 3. BaseWe make a base for the drilling machine; it must be very strong so that the entire structure does not fall down. You can use a piece of a suitable channel as a base. If there is no channel, it can be welded from thick sheet steel. We weld the ears to the base to secure the machine to the base with bolts.

READ How to properly sharpen metal drills with a grinder

We also weld 4 racks to the base; these can be pipes or iron rods. First, we insert the rods into the carriage, and later we attach them to the base. This is the only way to install the racks correctly.

Step seven. Finishing touches and tests We install a drill chuck on the gearbox shaft to screw the chuck, you can weld a nut for an angle grinder to it or cut the thread directly in the chuck.

We're painting the frame so it doesn't rust, now the machine looks great. We install a good switch to quickly turn off the machine if something happens. The machine is ready, the creator put a huge drill in the chuck and uses his monster to drill everything in order, from wooden beams to thick sheet steel.

The car showed itself perfectly, a machine for a real man. This completes the project, I hope you liked the homemade product and found useful thoughts for yourself. Good fortune and creative inspiration if you decide to repeat something similar. Don’t forget to share your thoughts and homemade creations with us!

Receive a selection of new homemade products by email. No trash, only useful ideas!

By filling out the form you agree to the processing of individual data

Tripod for angle grinder

Industrial tripods for mounting angle grinders. Allows you to make a cutting machine out of an ordinary grinder.

This mini machine solves the main problem when working with an angle grinder: if you hold the tool with both hands, it is extremely difficult to fix the workpiece. In this case, an angle grinder with a cutting disc is controlled with one hand, and with the other you can hold and move the piece of metal being cut.

Moreover, the tripod allows you to set the correct cutting angle, and the disk moves strictly vertically. The work is done efficiently and safely.

Craftsmen have long learned to make accessories for grinders for cutting metal and other solid compact workpieces on their own.

The frames are assembled from metal profiles, automobile shock absorbers, or even plywood. A well-made machine is no less reliable and safe than a factory one.

IMPORTANT! When working with any machine - factory or homemade, you must remember the correct position of the protective casing.

If your structure is strong enough and provides operator protection, you can use a tripod for sawing wood. The main thing to remember is safety.

In this case, the main cause of injuries – an uncontrolled grinder that breaks out of the hands when the disc gets jammed in the wood – has been eliminated.

But the disc itself can still cause injury.

Homemade tripod for mounting an angle grinder.

Therefore, when manufacturing such a device, it is better to make the switch non-fixed. For example, in the form of a foot pedal. Then you can instantly turn off the power if the device gets out of control.

When there is no need to work with wood, but only need to cut a large number of metal blanks, there are simpler options.

Such a mount can be made in an hour, and the ease of use will increase by an order of magnitude. If you know how your hands “fall off” after cutting fifty pegs from a metal corner, this design is for you.

Is it possible to cut plastic with a grinder?

At least the plastic ones

The panels cut very well.

You won't be able to cut straight

with a grinder If you need to accurately maintain the dimensions, then

a high-speed circular saw with pobedit tips is ideal for Typically, such saws are equipped with devices for setting dimensions.

Interesting materials:

How to connect to PS4 remotely? How to connect to a work network? How to connect to Share Play? How to connect to SQL? How to connect to telegram on a computer? How to connect to Wi-Fi by pressing a button on the router? How to connect to 5GHz Wi-Fi? How to connect to wi-fi without a password from iPhone? How to connect to Wi-Fi on Mtsk? How to connect to Wireless Display?

Homemade products, what you can do with your own hands, where to adapt the gearbox

A significant number of mechanisms operate at shaft speeds after the grinder gearbox. Therefore, there are more options for using an angle grinder gearbox for the operation of other devices. Together with non-standard ways of using an entire grinder for homemade products, masters of technical creativity create interesting compositions. Some are presented by the authors in specially filmed videos.

Sources:

https://moy-instrument.ru/podelki/chto-sdelat-iz-reduktora-bolgarki-svoimi-rukami.html