Icer

8067 2 6

Icer October 6, 2018Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

A shoe awl is made from a wooden file handle and a needle from an industrial sewing machine. With this awl you can sew leather and other durable materials. It is especially convenient to use for repairing shoes and bags, because the awl can be used in inconvenient places where it is impossible to sew a sewing line.

Step 1

As a basis for installing the needle, I used a small wooden handle, choosing the handle of a needle file for this purpose. Initially, after removing the file itself, a large round hole remained in it, which needed to be closed.

For these purposes, I used a furniture dowel, having previously drilled a hole for it using a drill of the required diameter.

Device and characteristics

An awl is a simple hand tool that consists of only two parts: a shaft and a handle.

The working part of the device resembles a thick game.

Its end can be straight, pointed, with a hook or hole.

A wide range of models of different types is presented in hardware and construction supermarkets, as well as in online store catalogs.

Material

The material used depends on the purpose of the tool.

The working part is made of high-quality, durable steel, which is subjected to heat treatment.

Manufacturers often use chrome vanadium steel and chrome or nickel plate the needle.

The rod can be straight, cone-shaped,

triangular, faceted, spiral, etc.

The handle is made of wood or high-quality plastic with rubberized inserts for more comfortable use.

Dimensions and weight

The sewing devices are quite lightweight and easy to use.

The weight of the models ranges from 40 to 150 grams.

Needle length – 10-40 cm, diameter – 2-4 mm.

There are other modifications, but they, as a rule, have a narrow scope of application and are used only when performing certain types of work.

Step 4

I mark the center of the handle and drill a new hole slightly larger in diameter than the base of the sewing needle.

Note! Instead of securing the handle in a vise and holding the heavy drill suspended, I do the opposite. This makes it easier to drill a hole along the axis. Do not make the hole too deep; it is better when the needle rests on the bottom in the working position.

Let me sum it up

- An awl with a hook is one of those ancient tools that have not yet lost their relevance today;

- Children's clothing and shoes are quickly consumable materials that require considerable expenditure to ensure that children are properly dressed and shod. Shoes are the most susceptible to failure;

- if you make an awl for stitching shoes, you can save on buying new clothes with the help of your skillful hands;

- For sewing shoes, it is better to make an awl with a hook. With this awl it is more convenient and faster to sew, and the seam is more reliable;

- After reading this note, you will not only be able to make an awl with your own hands, but also learn how to stitch shoes, which will allow you not to spend money on buying them again.

So simply, quickly and inexpensively you can make an awl with a hook with your own hands for stitching shoes. I hope that the technique of stitching shoes itself no longer seems to you like some kind of unusual skill. Everything is simple in this life, even if it seems difficult.

Write in the comments if this note helped you. By the way, if you are interested in how to put an inner patch on leather shoes, watch the video: WATCH THE VIDEO. That's all for me. Sincerely, Vladimir

.

Repost and win a laptop!

Every month on the 1st of the month iBook.pro gives away gifts.

- Click on one of the social buttons. networks

- Get a personal coupon

- Win a LENOVO or HP laptop

—>

LENOVO or HP from 40-50 TR, 8-16GB DDR4, SSD, 15.6″ screen, Windows 10

Step 5

To install the locking screw that secures the needle in the handle:

- I clamp the handle in a vice, additionally wrapping it with soft cloth for protection.

- I drill a hole at the end of the handle straight through the copper ring.

- I cut the thread with a tap.

- I screw in the locking screw that secures the needle.

A quick sew

There may be cases when an awl, which is very necessary at the moment, is not in the set of household tools, and it is not possible to acquire it in another way (buy, ask from a neighbor). In this case, you can make it from auxiliary materials. Their choice depends on the nature of the planned work.

To make a temporary awl you can use:

- a screwdriver of the required thickness. It will take a few minutes to sharpen it;

- wire, nail, knitting needle, sharpening which also does not require much time. They can be used without a handle if the quality of the material in which the holes need to be made allows. If necessary, you can make a primitive handle. For example, place a conveniently sized block on a nail; one end of the knitting needle can be bent and wrapped with electrical tape;

- needle file After sharpening, its handle can also be wrapped with insulating tape for safety and convenience.

There is a description on the Internet of making an awl using a failed car adapter. The craftsman installed a turned and polished self-tapping screw into it, like into a handle. It is clear that a hastily sharpened nail can be installed in such a handle.

Step 6

To polish a copper ring, I clamp an electric drill with a felt wheel in a vice and apply a polishing compound to it. Then I sand, achieving the perfect shine.

To do or not

Everyone makes a decision on this issue for themselves. In any case, a good tool made by yourself not only replenishes the home workshop, but also gives satisfaction to the master.

In addition, if created with special care, it can be a good gift.

Awl or Travel Sewing Machine

Good day, Comrades! While on vacation, I went into one of the airsoft equipment stores, and there I saw an unusual awl. The price tags said “Camping sewing machine.”

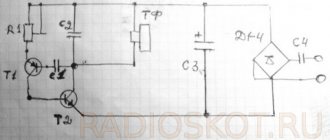

The price of this unit is 1600 rubles, hands went to the wallet, and the toad to the throat. The toad was losing and the brain came to its aid (yes, yes, sometimes it turns on for me). Well, he turned on and reminded me that my hands do not grow from my ass. And so, throughout my vacation I hatched a plan to manufacture such a unit. The main problem was the cartridge for fixing the needle. After rummaging through boxes of junk, I found a flexible shaft from an engraver (Fig. 1). Due to its Chinese origin and price of 200 rubles, it lasted about a month. Then it started to wobble and vibbbbrrr terribly.

I disassembled the shaft (Fig. 3). I sawed off the excess part of the shaft.

For aesthetic purposes, it was decided to use a shaft housing. sawed off the required, rounded part (Fig. 4).

In order not to ruin the thread of the cartridge and to temporarily fix it in the body, I insidiously and shamelessly expropriated a piece of plasticine from my son. I stuck it around the thread (Fig. 5), and then inserted it into the body (Fig. 6 and 7).

I took out a package of epoxy glue (Fig. 8) and spread it. I used a piece of plastic pipe as a handle. The cartridge entered with a gap of 1-2mm, which in principle is not critical. Having fixed the cartridge in the pipe with plasticine and placed the butt to the top (Fig. 9), I filled it with epoxy. I left the resulting structure overnight.

Early in the morning, after noon, work continued. Having removed all the plasticine, I drilled four holes in the almost finished awl, screwed in four self-tapping screws, thereby additionally fastening the cartridge body and the pipe (Fig. 10).

Again, to give it an aesthetic appearance, I stretched a heat-shrinkable tube over the structure. It turned out nice (Fig. 11). At this point I was struck by ha-ha. Shiloh became vaguely similar to the satisfactory one I saw with one good friend. Only the one was larger and more pimply.

Since the tube is hollow and very capacious, it was decided to use it as a kicker (Fig. 12).

Since there were no large needles, I had to buy regular sewing needles. I took a set of sewing needles for leather and thick fabrics. I selected the collet according to size (Fig. 13).

I refused the coil, it’s very inconvenient. The thread constantly unwinds and tightening the ties is inconvenient. I checked it, and in order not to confuse it, I decided not to post the process of installing the coil. In my case, the thread is clamped by a lid at the base of the handle. The test drive was a great success! The thread did not get tangled or twisted, the ties were almost even (Fig. 14 and 15).

That's all I have. Thank you for your attention! Ready to receive your slippers!

No instrument other than the awl has yet managed to win such popular love, expressed in numerous sayings, jokes and aphorisms. But finding the instrument itself on the shelves will be problematic. However, anyone can make an awl hook or any other shape!

Step 7

To make the thread feed channel, I drill a hole that starts in the center of the back of the awl and comes out the side.

Advice! Take the time to line it up exactly. Do not align the channel in one line with a screw at the other end.

Materials for production

Before understanding the question of how to make an awl, you need to decide another: what to create it from. The quality and type of the “homemade” product will depend on the materials used.

What is the rod made of?

The main element is the point, so it is important to choose what to make it from. There are several options

The list includes 4 possible candidates.

- Long self-tapping screw. This fastener can be considered the most popular contender when an awl is needed “here and now.”

- The same nail. If the choice falls on this product, then the craftsman needs to know that such an awl will have to be sharpened more often, because its material is softer.

- Electrode. This conductor, acting as an awl, requires additional steps: first it will have to be removed from the coating, and then sanded with sandpaper.

- Steel wire, long rod, knitting needle, bicycle needle, knitting needle from an old umbrella. These options do not require a large amount of work, since the preparation of the rod is limited to cutting and sharpening it.

The choice of material depends on the desire of the craftsman to make a high-quality tool, on what specific operations it is created for in the first place.

What can turn into a handle?

Equally important for an awl is a comfortable handle. But in this case there is a favorite material. This is wood. Typically, hardwoods are chosen for such products - birch, beech, oak, larch or bird cherry. If you have the opportunity and desire, you can use other materials: for example, high-quality plastic, textolite, thick plexiglass. However, in this case, the operation will become more complicated because additional equipment will be required to process them. If we consider the most unusual solutions, then the first places in this rating will be tools whose handles are made from an old toothbrush.

Step 9

After sanding, I apply drying oil to a napkin and polish the awl handle.

Awl as it is - from stationery to shoemaking!

Stationery hole punches, in a sense, can be called a form of evolution of the stationery awl, because once upon a time not a single paper production could do without it. It was the stationery awl that was the first to feel the effects of progress, giving way to a more advanced hole maker. An awl of this type is distinguished, first of all, by its rather “flimsy” design - a thin rod, a plastic handle. However, in order to pierce several sheets of paper you don’t need more.

- A shoe awl, which is often used in shoe workshops, has a stronger rod that can pierce the leather and a reliable handle.

- An awl-hook is also often called a shoe awl, but this is not true, since the previous option should be called the same. If you really want, then a shoe awl-hook. Its main difference from a regular awl is the tip of the tool in the form of a miniature harpoon.

- An awl with an eye, also known as a sewing awl, differs in that at the end of the point there is an eye similar to a needle, of different sizes. In many ways, the tool is capable of performing the same functions as the version with a hook, but it is still inferior in strength, so this type is much more often used in tailoring to work with suede, fabrics or soft leather

. - A triangular awl allows you to work with particularly hard materials, since the presence of three edges gives the rod a special strength. However, the holes are larger than when using a regular awl.

- An awl knife is a special type of tool that has gained popularity among Pu-erh tea connoisseurs. The fact is that pu-erh comes in compressed bricks or tablets, which should be divided into layers before use, preferably without damaging the compressed leaves. It is for these purposes that an awl knife is used, which, unlike a conventional tool, has a flattened and sharpened tip, which is convenient for separating tea.

Stitching with a shoe awl. Principle

Good time, friends!

And now we will learn to sew. The principle is general, you can learn it once, and then apply it as your imagination dictates. For example, you can sew a cut awning on a truck, a tent, a belt, a patch for a cover for something, and so on. Specifically, we will need this skill to sew the sole to the top (or the top to the sole - whichever is more convenient). Shoemakers themselves call a shoe awl a “ hook”

". Do you know why? Because it's a hook. An awl is a tool for marking and piercing holes. Although it is logical that kakbe is sewn with an awl, but then the prick should be called something else. For example, a piercing tool. But this is for linguists, yeah. So:

With a wooden handle - my worker. Learn - and you will be able to make handles (not removable) from any piece of wood, carve bulges and convexities into your hand and generally stop paying attention to it. In the meantime, it’s better to buy a pen. At first the hooks will break. And this handle has a convenient clip. And in general it is pleasant to the touch because of this fine notch. Closer to us lies the working tool itself - a consumable, in fact. Consider:

From left to right: Ketaets, new shopkeeper, worker. We see that Ketaets is somewhat wider (thicker). How to learn - that's it. The worker was once a shop worker about the same size. It needs to be sharpened periodically - and it wears off. There will come a time when it wears off completely and breaks. Like everything in our mortal world, in fact. Let's make a new awl out of it.

Article on the topic: How to properly dry your feet or shoes

We sew with threads. This is polyester, 1 mm, flat weave, impregnated. On the right is a fishing cord, this is how they sewed it before.

How to make a stitch? We pierce the materials to be sewn,

We make a loop of the inner thread with our fingers and throw it on the hook, catching it. You will need to learn how to do this by touch - the hook is not visible in the toe part.

The thread should catch all the way, completely. If we catch the edge, it will spread out when we pull it out. The wicker one can and will allow a few such liberties, but the twisted one will come with pesdets. Let's say it's in shoes. We find a hook and put it in a loop.

Pull it out and take the hook out of the loop.

And we insert the thread that comes from the outside into the loop. By hand, crochet, or something else - whatever is more convenient.

And we tighten it. We pull one thread with one hand, and the other with the other. We pull strongly, this determines how tightly we tighten the parts to be connected. At the same time, on thin materials the main thing is not to overdo it, otherwise the material will be deformed. When you come across these, you will understand. The overlap of the threads (knot) must be located in the thickness of the material. Here is an under-drawn stitch shown. You need to tighten the inner thread more. And so, without haste (but also without hesitation), stitch by stitch we sew the place we need. When we finish, we make a double knot or a backward stitch, and cut the threads.

And get your act together! This requires a lot of stress!

Thank you! Hello Cats

! Texts without the word “dick”: https://zen.yandex.ru/shuzprosvet. Group for asking questions and learning about shoe and shoe related topics: https://t.me/shuzprosvet

Possible duplicates found

How long do duct-taped shoes last?

You need to know the master!

It's a pity, I thought nano-insulating tape was invented.

I remembered a story from my childhood:

Mom: son, don’t wear these [new, beautiful, leather, just bought] shoes for a walk, better put on your old sneakers

me: yes, everything will be fine with them, I’m careful!

after a 200-meter downhill on rocky scree, I was carrying in my hands an assembly kit: 2 soles + 2 blanks (now we know that the top is called a blank), people walking by wondered why I was walking barefoot, but I walked and thought that fucked up is inevitable

None of the people were at home, but there was a white nylon thread and an awl hook. the technology was unknown to me, so I came up with it on the fly, cut the thread longer so that it was enough for 2 passes and went to sew the sole to the workpiece. an hour later the first half-pair (fuck, I’m just throwing out terms!) was ready, after 40 minutes the second was ready, although there was still half an hour left before the mother arrived

but bad luck - someone screwed up the holes on the right shoe and they almost matched! There was no time to rip it apart and re-stitch it. the threads were quickly painted over with shoe polish, the boots were thoroughly cleaned, although the appearance of new ones was lost forever

I had to walk in a terribly uncomfortable right shoe for a couple of days, but then the operation was repeated more successfully, and the shoes served for another couple of years

Article on the topic: How to remove a store magnet from shoes