What types of caracats are there?

Before figuring out how to independently make a karakat swamp rover from improvised mechanisms, it is necessary to take a closer look at the existing varieties of this kind of product. The Karakat swamp all-terrain vehicle is nothing more than a non-standard vehicle that moves with the help of wheels on which low-pressure tires are installed.

Among its main advantages:

- excellent maneuverability;

- low cost;

- maintainability;

- high power (depending on the spare parts used).

Such mechanisms are most often constructed independently on the basis of some equipment, for example, a tractor or walk-behind tractor. Existing models differ from each other not only in characteristics, but also in design. The most widespread are all-wheel drive and three-wheel drive devices.

All-wheel drive

All-wheel drive models seem to be the most popular transport option among consumers. They are equipped with 4 wheels, thanks to which the design is stable and has high maneuverability. Such a caracat can overcome even impressive obstacles without any problems, but its assembly will require two wheels of the same diameter.

To make such a swamp vehicle, the breaking with your own hands must be done correctly, otherwise there is a high probability of assembling an inoperable structure.

Three-wheeled

An equally popular modification can be considered models of swamp vehicles with three wheels. Such vehicles are lightweight and have the same cross-country ability as their all-wheel drive counterparts. Such an option will be optimal if you need to quickly make high-quality karakat. Do-it-yourself fracture can be done if you have the necessary equipment.

Stages of creating a homemade karakat

If you want to construct a Vologda swamp vehicle, the Karakat, or its other models at home, you should first of all purchase the necessary tools in advance, as well as acquire suitable components.

The complete list of necessary components and tools may vary and directly depends on the selected vehicle model that is planned to be manufactured. When analyzing the assembly process of such a product, it is necessary to highlight several important stages:

- Selection of the frame of homemade tractors or motor vehicles, which will become the basis of the future device.

- Planning and assembly of the rear axle and vehicle suspension.

- Selection and installation of suitable wheels.

- Installation of the power unit.

Since these types of elements seem to be key in the design of a swamp vehicle, it is advisable to consider the features of their selection and installation in more detail.

The main structural element is the frame, on which other components and assemblies will be installed in the future. Its choice directly affects the appearance of the future caracat, as well as its performance characteristics. Experienced craftsmen recommend using the frames of old domestically produced motorcycles, for example, IZH or Ural, since it is much easier to make a karakat from a motorcycle than from a car.

Spare parts from them are characterized by low cost, high strength and optimal characteristics for use as the basis for a swamp vehicle. After all, such three-wheeled models boast high maneuverability and maneuverability, which makes them universal. During the manufacturing process, it is advisable to use a frame drawing due to the complexity of the assembly.

Suspension

When designing the chassis, it is strongly recommended to give preference to an independent type of suspension. This is due not only to the ease of its manufacture, but also to its excellent characteristics.

How to make a walk-behind tractor from a chainsaw

The following products and materials are used:

- Motorcycle steering wheel.

- old from the transmission of a moped.

- Stainless steel pipes with a diameter of 20-30 mm.

- pneumatic tires from wheels from a car or agricultural machinery. An alternative homemade option is metal rims with lugs. They will require the manufacture of a steel sheet and a corner.

- Bolts and chainsaws.

The engine is removed from the nut. It is recommended to take a professional tool with a 10-13 hp motor.

The work is performed in the following order:

- The stainless steel pipe is bent into a U-shape. The ends. the frame of the “legs” must be bent and strengthened.

- up the structure with jumpers made of the same material.

- The steering wheel is welded.

- The plate for installation with the battery is secured using electric welding.

- A muffler is made from a piece of pipe with a diameter of 7 cm and a length of 250 mm. The internal space is filled with sawdust so that the size of the outlet hole is no more than 1.6 cm.

- A small U-shaped frame for the engine is made from a pipe with a diameter of 4 cm. Bolt brackets are welded to the middle and at the edge. Install.

- mount the motor to the frame and screw it on.

- The reinforced axle shafts are secured with a cotter pin and the wheels are installed on them.

- During the completion process, the steering wheel, gearbox and Remains are attached.

Reworking a walk-behind tractor

Walk-behind tractors are rightfully considered one of the most versatile types of agricultural machinery, which is why they are often used as the basis for various home-made units. Among them, home-made 4x4 mini tractors with a breakable frame are very popular, as well as caracats made from a walk-behind tractor, which in terms of technical indicators are in no way inferior to other types.

To successfully manufacture such a device from a walk-behind tractor, you will need to follow the following instructions:

- Weld the frame using a metal profile/pipe.

- Mount rear and front drives. To simplify the process, it is recommended to take the front axle, steering system, and other elements from the vehicle’s chassis.

- Install the motor, as well as the gearbox included in the design of the walk-behind tractor.

- Construct and secure the slopes, and then roll in the resulting structure.

It is important to note that for this type of swamp vehicle it is recommended to use a wheelbase with increased belt-type traction. Structures made from walk-behind tractors, as a rule, have impressive dimensions and can reach speeds of up to 70 km/h, which makes them universal and reliable off-road solutions.

In order for the karakat to have the necessary characteristics, it is necessary to use high-power walk-behind tractors, since the vehicle must not only move successfully, but also transport the driver, as well as various loads.

main and device nodes

The all-terrain vehicle consists of the following carrier:

- frame components.

- Engine. Preferably the rear one, otherwise the car will nod off.

- Chassis parts: chassis, clutch, independent suspension, etc. soft All-terrain tires with increased steering are installed.

- control diameter.

- Cabins.

The three-wheeled version is controlled using a simple motorcycle wheel.

In a 4x4 vehicle, one of the following mechanisms is used:

- automobile rotating unit;

- breakable frame type.

The second option allows you to achieve high maneuverability with a long length. A vehicle with a frame like this is called a “perelomka”. It consists of 2 parts, connected by a rotary fist.

This unit can be borrowed from the front axle of a UAZ vehicle. The “turning point” principle is used, for example, in “accordion” trolleybuses, the T-Vmesto tractor, etc.

150 pneumatic wheeled chassis, the machine can be equipped with tracks.

Homemade caracat from a walk-behind tractor with your own hands

The topic of homemade vehicles is especially popular today. Many “traditional craftsmen” try to make carakat from standard means of transportation and special equipment. How can you make a budget karakat using a walk-behind tractor (even the simplest Neva will do). At first glance, doubts arise about the quality of the equipment, because visually it is a bulky and at the same time inconvenient machine. In fact, a caracat made from a walk-behind tractor, made with your own hands, shows simply excellent performance characteristics and can easily move in harsh climates and difficult terrain. And if we talk about moving through swamps, various river mouths, and in mud, then such an all-terrain vehicle will simply become an indispensable solution for every person.

Especially than caracats

The vehicle contains:

- Wheeled chassis.

- Lightweight cabin.

- low pressure tires (soft, oversized).

The machine has the following features:

- It surpasses tracked tractors in cross-country ability.

- Overcomes swamps and small rivers.

- Unlike all-terrain vehicles with steel tracks, they do not cause damage, keeping the vegetation cover intact.

The name of the swamp bug comes from the word “cuttlefish”.

Stages of karakat development

Conventionally, we can distinguish the following stages on how to assemble a floating caracat:

- Creating a Frame

- Making a pendant

- Creation and installation of wheels

- Engine and systems installation

Caracat frame

First of all, you need to choose a suitable frame for installing all the necessary equipment and units on it. It is desirable if it is a walk-behind tractor belonging to the medium or even heavy class of equipment.

In fact, even the most “advanced” karakat is nothing more than a homemade all-terrain vehicle, which is usually mounted on a frame with four (4x4) or even three wheels (tricycle). The choice of the number of wheels depends solely on the design features of the intended vehicle and the previously developed design.

The wheels must be “shod” with high-quality low-pressure tires; the structure is powered by an installed powerful internal combustion engine.

Suspension

The suspension of a walk-behind tractor will require special attention and precision on the part of the developer. At this stage, in addition to the suspension itself, the master will need to make a rear axle, which is done exclusively with his own hands.

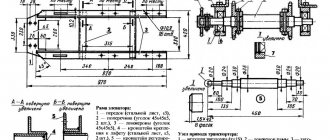

Rear axle drawing example

The suspension provides a special design made of two separate parts connected together by hinges. In this case, the spars must mate with each other, for which a steering bushing is used. Ultimately, it is possible to form independent front and rear suspensions.

The main condition is to achieve exceptionally high suspension independence, because It is this indicator that allows the all-terrain vehicle to be operated in the most unpredictable places, guaranteeing the safety of the structure.

Maneuverability and cross-country ability should be the primary factors that you should pay attention to when making a homemade caracat design from a walk-behind tractor.

Do-it-yourself karakat wheels

Caracat wheels are, in fact, the most expensive product, which requires a lot of time to be spent on. You can either purchase ready-made disks or try to make them yourself. It is worth noting that almost all vehicles (karakats), made as homemade products, are equipped not with wheels directly, but with tires and low-pressure chambers. Especially for these purposes, it is best to choose products installed on trucks such as the Ural, KamAZ and others.

As an option, you can use wheels from the trailers of these vehicles - if possible, you can purchase tires and a tube from the K-700 model. The most important thing to pay attention to is that the wheels must be large enough, which will allow you to easily move off-road in the future, easily covering significant distances without the risk of overturning.

Engine and systems

Installation of the engine and other systems is carried out at the last stages of work. These operations are carried out when a suspension with prepared wheels is installed on the vehicle frame.

In addition to the engine, clutch systems, brake elements, as well as systems responsible for removing burnt fuel products from the mechanisms are mounted.

When the engine is installed, it will be necessary to conduct a full test of the karakat, then it can be operated.

It is worth noting that depending on the walk-behind tractor used as the initial unit, the power of the vehicle can be calculated.

For assembly you will need to use a standard set of tools and technological equipment and available materials. It is important to ensure the maximum possible safety of the vehicle driver and eliminate the possibility of accidents. A self-constructed karakat from a walk-behind tractor will allow you to move without problems in harsh weather conditions and will last for a long period of time without the need for regular repairs and expensive maintenance.

Karakat fracture with a VAZ engine

Message by Stanislav Ozerny » January 16, 2012, 05:43 pm

The equipment is as follows - engine - VAZ 2101, transfer case - Niva, axles - VAZ 2103. Wheels - tattered combine harvesters. the frame is a square sawn lengthwise. "perelomysh" - fist from "UAZ". gearbox - VAZ 2108. cladding - thin tin with rivets.

The weight turned out to be quite heavy, 1000 kg. Ground clearance is 50 cm, but there is enough power.

and here are some videos from the second tests. During the first tests, because the welder was in a hurry to get to his wife, the bridges fell off. poorly welded. but then, repenting, he corrected everything in good conscience.

Post by SashaKU » Jan 16, 2012, 6:22 pm

Post by lunatik-1 » Jan 17, 2012, 01:09

I've always been skeptical about low-lying gas pipelines

and the title for the topic needs to be changed

Post by School » 17 Jan 2012, 15:35

Post by Stanislav Ozerny » 17 Jan 2012, 16:15

Post by Yves Bel » 17 Jan 2012, 16:40

Post by Аleksandrrr » Jan 17, 2012, 4:45 pm

Post by Stanislav Ozerny » 17 Jan 2012, 16:45

Post by Stanislav Ozerny » 17 Jan 2012, 18:34

Post by drogs » 17 Jan 2012, 21:02

Post by lunatik-1 » Jan 18, 2012, 01:40

Yes maybe

But not everyone

Post by Stanislav Ozerny » 21 Jan 2012, 19:12

forest and field trials of the caracat took place today. In all honesty, nothing more than a snowmobile fails. and on bushes, branches, etc. a snowmobile and a UAZ are nervously smoking on the sidelines.

Of course, there are a lot of impressions. Excellent cross-country ability in snow. but there are several questions along the way: blocking. Do you need to travel on it constantly? How much does it affect the distribution of forces between bridges? Or is it better to turn it on only before a difficult section?

and in the end it cut off the axle shaft. the replacement lasted 1.5 hours.

Source

DIY karakat

The main feature of this swamp vehicle is its reliable design. During production, I proceeded from the availability of serial units that our industry produces. As an all-terrain vehicle engine, I used the existing one from IZH-Planet. I installed forced air cooling on it from the SZD motorized stroller, popularly known as “Invalidka”.

The crankshaft was kept from the original planetary one, because The seat for the generator at the SZD is not suitable, a smaller one is needed. I installed the ignition coil on the swamp vehicle from IZH at 6 W (photo 1)

.

Frame, brakes and transmission

The supporting structure is the IZH-Planet frame. I digested and strengthened it using profile pipes 20x20x2.5 mm, 40x20x2.5 mm (photo 3)

.

The front fork measuring 40x40x2.5 mm was made from the same material (photo 4)

.

The peculiarity of the chain drive from the engine to the gearbox is the modification of the unit for installing the driven star on the gearbox input shaft. To relieve the load on the input shaft bearing and eliminate the possibility of bending, I installed a separate bearing with a torque transmission unit.

The node consists of:

✔ from a clutch disc from Oka, ✔ IZH-Planet gearbox cover with drive gear and bulk bearing, ✔ sheet of steel (3 mm thick, d 120 mm) for transmitting torque and mating the clutch disc with the drive gear, ✔ plates made of sheet steel (of the same thickness) to install the entire assembly at the Oki checkpoint

(photo 5)

.

The power transmission gear ratio was calculated using the formula:

N = n1хп2хпЗх. ni, where n is the gear ratio of each gear in the transmission.

I calculated it so that the torque that the engine develops (taking into account downshifts) does not exceed the permissible torque maintained by the Oki gearbox.

Braking system - VAZ-01 with brake drive from the handbrake cable. The cable was adapted to the standard motorcycle lever.

The chain tensioner was used from a VAZ-08 tension roller. The wheel drive was made from an Oka CV joint and a VAZ-01 axle shaft, connecting them by welding. I secured the axle shaft in its normal place (in the flange part cut off from the VAZ axle).

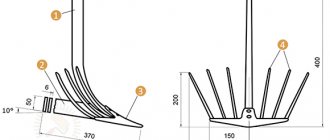

All-terrain vehicle wheels. I took wheel rims from BA3-13 as a basis and welded the spokes and rims on a homemade machine (consists of a construction pallet and plywood, 4 studs and a brake drum for fixing them) (photo 6)

.

Tires size 500×70-R20 were taken from a heavy all-terrain vehicle. I assembled them according to the “camera within a chamber” principle and tied them together with belts from a conveyor belt (photo7)

.

The karakat turned out to be light and with good cross-country ability!

Video selection

Karakat-all-terrain vehicle based on the Neva walk-behind tractor:

A lightweight all-terrain vehicle with the working title “Bruise”, as the body is sheathed in polycarbonate. In general, this is the first model where this light, warm and more or less durable material was used. So far there are no complaints about polycarbonate, this plastic should withstand frosts of up to 40 degrees and does not deteriorate in the sun, most importantly, it is much lighter than any iron and aluminum and cheaper.

The all-terrain vehicle turned out to be quite light for its size, capacity and large wheels. Approximate weight is about 600kg. Dimensions: length-3400 mm, width-1960 mm, cabin height 2100 mm, kung height 2350 mm.

Technical characteristics of the all-terrain vehicle

Rotation method

— “fracture” of the frame on the UAZ fist Wheel

formula

— 4x4, permanent all-wheel drive

Dimensions

— L*W*H /3400*1960*2350

Curb weight

— 650 kg

Load capacity

— land/water 300/150 kg

Maximum speed

— land/ water 25/1 km/h

Engine

- IZH-Planeta3, converted to liquid cooling

Chain gear

- chain pitch 19.05 mm, gearbox inverter = 2.13

Drive axles

- M-412, main pair inverter = 3.9

Tires

- Bel -79 1020*420-18, chamber

Discs

- homemade

Frame

- spatial, welded, made of profile pipes

Cabin

- semi-closed, single-seat

Body

- semi-closed, lined with polycarbonate

The all-terrain vehicle was built as a simple and budget option. The engine was planned from the SZD motorized stroller, but the Soviet heritage remains less and less and now it is difficult to find old engines and other elements as people sell everything for scrap. But we still managed to find other necessary parts for the “planetary” engine. The engine turned out to be prefabricated, based on Planet 3, but with the right half replaced for a 12-volt generator.