A flat cutter-ripper for a walk-behind tractor is a type of attachment whose function is to remove weeds. During operation, this device quickly cuts off the stems of harmful plants, leaving them to rot in the area. Subsequently, the weeds are converted into high-quality organic fertilizer, which can significantly accelerate the growth and development of cultivated crops.

What functions does a flat cutter for a walk-behind tractor have?

With it you can:

- weed beds and garden plots;

- thin out and hill up the planting;

- create your own beds;

- fill the holes;

- level the soil;

- loosen the ground quite deeply, etc.

Previously, people used manual flat-cutters, but with the advent of walk-behind tractors and specialized attachments, the ability to perform the above-mentioned tasks with less physical effort and greater productivity became relevant.

How much oil to pour into the walk-behind tractor gearbox

When operating the walk-behind tractor, it is necessary to maintain a constant oil level in the gearbox. If this simple rule is not followed, lubricant residues may boil and jam the parts. Only high-quality oil is poured. Even with constant maintenance of the level, breakdowns occur. During chain transmission, the chain breaks or is pulled out. If traces of oil appear on the outside, this is a sign of leaking seals. Worn parts require replacement with similar ones. It is better to purchase them from a reputable manufacturer.

The gearbox ensures uninterrupted operation of the walk-behind tractor, extends its service life and increases the efficiency of use of the unit. A good helper in this matter is to lubricate its parts. Transmission oil is poured in for lubrication. Its possible brand is ZIC 10W40, Super T-3. The oil level is determined in this way:

- you need to take a wire approximately 70 cm long instead of a probe and bend it into an arc;

- insert into the filling hole until it stops;

- pull the homemade dipstick back;

- the wire should be oiled to a length of about 30 cm.

This level is considered to be the norm. If there is little oil, you need to add it to the norm. In a purchased gearbox, the level must be indicated in the instructions. A Chinese walk-behind tractor can be sold without oil.

How to work correctly with a flat cutter for a walk-behind tractor?

- To loosen and weed the rows, point the blades to the left, flat on the soil;

- To get rid of tall weeds as efficiently as possible, you also need to point the blade to the left and lift it a little;

- To create the beds themselves, you need to turn the blades down, then the result will be excellent;

- To plant seeds and form ridges, the blades should be turned to the right, flat on the soil.

In principle, each owner is free to adapt the existing unit to individual requirements, as well as test its capabilities, so in this case experiments are encouraged.

Lancet cultivator

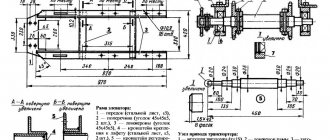

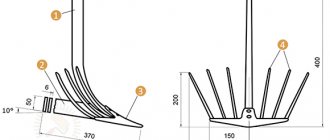

The unit has a simple design and does not require combination with other equipment, but at the same time produces good results in cultivating the land. The output is a lancet equipment with five working arms. The basis of the structure will be formed by a rocker-shaped frame, also made of steel corners. Lancet-type flat-cutting paws are installed on it. You can get such elements from the factory walk-behind tractor KPN-4A. It is necessary to fix the cutting components so that one middle and two outer legs are installed in a checkerboard pattern. Their connection should be provided by an articulated frame on springs. The estimated working width with these paws is 33 cm.

How to create a flat cutter for a walk-behind tractor with your own hands?

If a person does not want to spend extra money on factory-made attachments, he can create a homemade addition using available parts and tools. Moreover, even a classic Fokina flat cutter is suitable for adapting to the features of walk-behind tractors. First, we should familiarize ourselves with the diagrams and drawings presented on our website.

Algorithm for creating a classic version for a walk-behind tractor:

- First, you need to heat a piece of metal on a blowtorch, which will later become the blade;

- Using an encryption machine, it is necessary to sharpen it into a knife;

- It is worth making certain holes for placement as attachments;

- Having attached the products to the drawings, you need to determine the places that will be bent;

- Having heated these very fragments with a blowtorch, we give the blade the desired shape (for this task you can use an adjustable wrench);

- Afterwards, the finished flat cutter must be cooled (preferably in water);

- Having attached the device, you can start working.

If the land owner believes that options like factory cutters may be more practical, he is free to follow further operations to create a more modernized type of the mentioned device:

- You should find a small diameter and short pipe;

- Then make several holes in it at equal distances;

- Afterwards, it is important to find 2 small rectangular sheets of steel, give them the required shape, sharpen and weld them together in the shape of a boomerang;

- The final step is to connect (also using a welding device) the “iron boomerang” to the pipe (base).

In principle, creating such simple “helpers” is not a difficult task, the main thing is to have the necessary tools, parts and desire.

Rotary disc cultivator

This is a more serious unit, with the help of which you can perform loosening, leveling the soil, and hilling. In its design, a homemade hiller cultivator assumes the presence of the following elements: a disk, an axle, a rod and bushings, large and small brackets, a handle and a pipe. The functions of the working components are performed by discs welded to the bushings. The latter, in turn, are placed on the axis of the cultivator. The axial ends are secured in the brackets using a cotter pin. A pipe with a crossbar and a handle is installed in a large bracket in special grooves. A rod 25 cm long and 2.4 cm in diameter is installed on the smaller bracket (by welding).

A 1.6 cm thick rod is also screwed into the rod, which should protrude slightly above the level of the crossbar. The most difficult thing in making this model is giving the disks a spherical shape. In general, this is a common question among gardeners and summer residents who are interested in how to make a homemade cultivator with reliable working elements. Without special equipment, there can only be one way - to change the shape of the disks with a hammer, forming a bowl in the central part. Next, it is important to calculate the angle of fixation of the spherical disks in relation to the processing direction. This parameter must be adjusted using thumbscrews installed on the crossbar.

Increasing the power of the walk-behind tractor will allow you to use the unit as efficiently as possible

A walk-behind tractor is an indispensable thing for farmers. Increasing the power of the walk-behind tractor allows you to increase the productivity of equipment and speed up agricultural work. You can improve your equipment either with your own hands or by purchasing the necessary equipment.

You can increase the speed of the walk-behind tractor in the following ways:

- replacing a gear pair;

- installation of wheels with a large diameter.

Increasing speed in the first way is a rather complicated process. Therefore, without knowledge and skills in this area, it is better not to do this yourself and contact a special service center. If you have the necessary skills, you can make the replacement yourself.

Just like any other equipment, the walk-behind tractor has several speed modes controlled using gears. The walk-behind tractor moves at a speed of 2 to 15 km/h. The larger gear usually has 61 teeth, and the small one – 12. To increase the power of the walk-behind tractor, the gear pairs of the gearbox are replaced.

Maximum speed can be achieved by increasing the number of teeth on the gear.

When replacing a gear, be sure to select the correct pulley. If the pulley is selected incorrectly, the walk-behind tractor may stop working.

To increase the speed, you can install tires with a diameter of 70.4 cm; such a replacement will help speed up the walk-behind tractor several times. If the arches in which the tires are placed allow the installation of wheels with a larger diameter, you can try to increase them by a few centimeters.

So, how to improve a motor cultivator with the help of weights. You can buy them or make and install them yourself. Weights are installed on the frame and wheels. Wheel weights are made of solid profiles and steel wheels. The body is weighted using special removable frames and a corner. Loads with different weights and configurations are attached to the frame.

So, sometimes you need to make a motor cultivator quite heavy, you can use reinforced concrete products.

Such loads can load the walk-behind tractor quite well. With the help of such simple devices, the range of application of technology is significantly expanded.

A homemade snowmobile can be equipped with a sled to transport property or feed for animals, or go fishing or hunting.

We suggest you familiarize yourself with How to plant walnut chestnuts at home

Setting the reverse speed on a walk-behind tractor is another way to improve the walk-behind tractor. The presence of reverse depends on the sizes and models. It can work on any type of equipment, it all depends on the tasks assigned to the equipment, be it a light or heavy walk-behind tractor, or a motor-cultivator.

Gearboxes are:

- gear;

- reverse gear;

- angular;

- downward

A gear reducer is a transmitter that operates between the wheels and the motor. The reverse gearbox consists of a clutch located between the gears and located on the main shaft. The corner is responsible for the operation of the transmission with the engine, which affects power.

The reduction gearbox is responsible for reducing the speed, which helps increase power. The main task of this system is to provide reverse gear. To make this mechanism at home, you first need to make a body. Then select the necessary parts.

But it’s better to buy a ready-made gearbox.

Walk-behind tractors are sold with a minimum number of components. However, a milling cutter and a standard plow are not enough to perform all agricultural work. How to improve a motor cultivator using scrap materials? With the help of tools that are in every home, you can expand the capabilities of the walk-behind tractor. Equipment that you can make yourself:

- Installation of a rake on a walk-behind tractor for collecting debris, leaves, and hay. Such a simple device will speed up autumn field work and allow you to clear large areas of debris in a matter of minutes. To make a rake you will need: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. The reinforcement is cut into pieces 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase maneuverability, the rake can be equipped with roller wheels.

- A trailer and cart will help transport large loads. The cart can be made from scrap materials - channel and old car wheels, metal profiles and boards. The clutch is made standard for both tractors and cars.

- If desired, you can make a potato digger, hiller and harrows, which will not be inferior in quality to purchased ones.

Another device for cultivating soil using a walk-behind tractor is a plow.

The following types of plows are distinguished:

- The easiest to use is the single-hull one, also known as the Zykov plow.

- Reversible plow for walk-behind tractor: rotary or reversible. The upper part has a curved feather, which turns the soil over during plowing. A universal device that easily copes with plowing heavy soils. Quickly copes with the treatment of areas with clay and marshy soil.

- The rotary plow for a walk-behind tractor has a complex design. Depending on the number of ploughshares, there are two-body and three-body models. Active plowshares dump soil in one direction only, while passive plowshares level the beds and lift them. Tilling the soil with such a plow has a number of advantages: the soil is maximally saturated with oxygen; tire wear and fuel consumption are reduced; after processing there are no large clods of earth left.

- A rotary plow for a walk-behind tractor provides unlimited possibilities. During operation, the axis rotates, and with it the soil layers. It easily plows even very hard soil at a depth of about 30 centimeters. There are paddle, drum, shovel and auger plows. Devices of the first type are equipped with a rigid pusher and can consist of a spring plate or be combined. Units of the second type are equipped with a disk with blades that rotate during operation. A plow with a disc blade for a walk-behind tractor is suitable for work in early spring; it copes well with wet soil.

Any of the above plows can be made independently, taking into account the design features and following the instructions and diagrams. You can also improve an already purchased plow.

A rotary reversible plow for a walk-behind tractor copes with the processing of plots most efficiently, thanks to the optimization of the plowing process. And it is most in demand among agricultural workers.

Thanks to the expansion of capabilities, the walk-behind tractor becomes universal. It can be used to solve a variety of tasks from field work to snow removal in winter.

About the device of the walk-behind tractor

Next, you will find out which walk-behind tractor is better to choose. To make it clearer what the principle of homemade walk-behind tractor manufacturing and its additional components is, you need to consider in detail the structure of the walk-behind tractor as a means of small-scale mechanization. So, this unit includes several main working units:

- The main driving force, i.e. engine.

- Transmission.

- Chassis.

- Basic controls.

Engine

The main driving force in the design of walk-behind tractors is a standard internal combustion engine. Depending on the type and brand of walk-behind tractor, for example Cayman Vario, Patriot Ural, Texas, Foreman, Crosser, Viking, Forza, the engine used may be different:

- Gasoline 4-stroke engine. This engine is used for units belonging to the light and medium class of devices.

- Diesel 4-stroke engine. Motors of this kind are used on heavy and powerful walk-behind tractors designed to work on the most difficult surface areas.

Video: The best diesel walk-behind tractor

For more information about the operation of a diesel walk-behind tractor, watch the video:

Of course, 2-stroke engines are also available, but they are used in fairly old models of walk-behind tractors, being significantly inferior to 4-stroke engines in terms of power thrust. However, most consumers get 4-stroke gasoline engines. Their device includes the following systems:

- The system responsible for supplying fuel. Consists of a fuel tank, carburetor, air filter and fuel hose.

- A lubrication system that carries out the process of lubricating those parts that rub against each other.

- A starter that spins the crankshaft.

- A cooling system that removes heat from the engine cylinder block using air flow.

- An ignition system that produces a spark at the spark plug.

- A gas distribution system that ensures the flow of the air-fuel mixture into the engine cylinder and is also responsible for the exit of exhaust gases.

The important thing is that the engine is sold with all the main operating systems, which greatly facilitates the process of making a homemade walk-behind tractor.

Transmission

The main function of the transmission is to transmit torque from the engine to the wheelbase, as well as regulate speeds and change the movement of the unit. Its design includes several working units: gearbox, clutch, gearbox and differential (not available in all models).

Transmission can be of several types:

Basically, the classic type of gear transmission is used on heavy walk-behind tractors, and it consists of bevel and cylindrical gears.

Other types of transmission are used in light and medium types of walk-behind tractors. At the same time, regardless of the type of transmission, the design contains a PTO - a power take-off shaft, which transmits torque to the working units of the unit.

As for the clutch, it can be different:

- In the form of a V-belt transmission. The essence of the process is the clutch lever, which tightens or loosens the belt, thereby transmitting or stopping the transmission of torque from the motor to the gearbox.

- Single or multi-disc dry or wet clutch.

- Conical coupling.

Most high-quality walk-behind tractors Sadko, Don, Huter, Profi, Plowman, Champion, Carver use the second type of clutch, which is the most reliable.

All about creepers for walk-behind tractors

Motorized equipment, in particular, walk-behind tractors, have been faithful assistants for owners of agricultural plots for many years, capable of carrying out a wide range of work with the least amount of effort and time. However, sometimes the operational parameters of these units are no longer sufficient to carry out certain tasks, or the equipment functions poorly. In this case, a device such as a stroke reducer (reduction gear) for a walk-behind tractor will help to cope with individual problems.

What is a creeper and what is it intended for?

Gardening equipment can be made even more efficient and functional if you use additional equipment with it.

Such devices include a speed reducer for a motor cultivator. This kind of product is quite simple to make yourself, as a result of which you will receive an effective tool that helps reduce the speed of movement of the cultivator. Most often, a creeper is used in conjunction with pneumatic wheels. A little less often, the equipment is used in conjunction with wheels equipped with lugs. This helps to significantly improve the adhesion of the cultivator to the ground, which is often required in conditions of very loose and soft soil.

It is often necessary to slightly reduce the speed of the cultivator when the operator needs to direct the power of the cultivator not to its speed indicators, but to increasing torque or increasing traction.

Purpose of a reduction gearbox

A speed reducer is a conventional reduction gearbox that increases torque by reducing engine speed. The operation of the creeper is rational: when cultivating fertile or uncultivated land, deep plowing, transporting heavy loads, or using heavy attachments. During daily work in such conditions, it is necessary to carefully control the work procedure.

The correct solution would be to slow down the engine speed and work at the lowest speed. However, in such a situation, power is also lost, which is unacceptable. This is where walk-behind gear reducers come to the rescue. They make it possible, without reducing engine speed, and, therefore, without losing power, to gain optimal control over the processing procedure, and even increase power.

If you have some experience and skills, you can make a gearbox with your own hands, using readily available materials and equipment, or purchase an already working product, the range of which is large on the agricultural machinery market and is available to consumers with different capabilities.