A vacuum pump is a regular air compressor that uses the suction side.

You can make a 12 volt vacuum pump out of an air compressor if you can connect a hose to its air intake.

This guide will show you how to make a vacuum pump with your own hands. Such a device is useful for vacuumizing food products and increasing their shelf life, or for vacuum packaging things, since a bag with removed air takes up less space than a regular bag with things. You can also do vacuum molding - the production of products from thermoplastic materials in hot form using vacuum.

The vacuum created by such a device is several times higher than what a conventional vacuum cleaner can create (about 0.8 kgf/sq.cm, or 0.08 MPa).

This vacuum is sufficient to use the pump for industrial purposes that require vacuum.

A compressor for inflating car tires in a store costs about 1,300 rubles. You will also have to purchase some spare parts and glue.

You will also need:

- About one meter of PVC tube with an internal diameter of 6 mm.

- Plastic herringbone connector for 6mm ID tubing.

- Epoxy resin (cold welding).

All of these materials are readily available and can be purchased at the store.

Since a 12V pump draws about 4A of current, it will need a fairly powerful DC power supply. A 6 A car charger can be used as a power source.

NOTES.

If you use a cheap air compressor to inflate your tires, like the $700 Harbor Freight one, don't expect too much from it. (A cheap pump will only work for a few minutes, then it will overheat. A good compressor can work continuously for up to an hour). The fact is that the compressor is not designed to work as a vacuum pump. Turn it on for a period of 1/3 to 2/3 of the time specified in the compressor data sheet, then let it cool for 5 minutes.

For example, if the passport for an air compressor indicates a continuous operation time of 15 minutes, then in vacuum pump mode you can run it for 5-10 minutes. with a break of 5 minutes. for cooling. A good pump is one with an aluminum cylinder, a large area of cooling fins, a cooling fan and a powerful motor designed to last for a long time.

Here are some tips on using the pump and its limitations:

For vacuum packaging:

- Do not use the pump to vacuum large volumes of food or items, or to create a vacuum in a container with air leaks.

- Use small containers for vacuuming and fill their volume with products (things) to the maximum in order to pump out a minimum of air from them.

- Turn off the pump from time to time to cool it down.

- If after a long time the pump cannot create a vacuum, then there is a leak somewhere.

For vacuum forming:

- Do not attempt to remove air from a 100 liter tank with this pump.

- To reduce the load on the vacuum pump, use a two-stage air pumping system: first, most of the air is pumped out using a vacuum cleaner, then a vacuum tank with a vacuum pump is put into operation: link.

- Do not start the pump until the vacuum in the system drops to 0.8 kgf/cm2. Typically, a vacuum in the range of 0.6-0.7 kgf/cm2 is sufficient for molding products. Therefore, you should not once again turn on the vacuum pump to increase the vacuum by a couple of tenths of atmospheres, in order to avoid its rapid wear.

What is a vacuum?

Yogis were the first to use this exercise. The meaning of the vacuum is to alternately contract and relax the transverse abdominal muscles in combination with a special breathing technique.

4 rules of yoga for a healthy body

These muscles are among the most difficult to reach, so they are difficult to reach with classic crunches. But they are the ones responsible for the tone of the abdomen and the wasp waist.

Vacuum is one of the few exercises that can pump up the transverse abdominal muscles.

Photo: istockphoto.com

Operating principle

The main area of application of vacuum presses is the furniture industry, where such equipment is used in the production of elements of cabinet and upholstered furniture - for gluing elements of furniture structures with PVC film and veneer, which perform primarily decorative functions. The tasks of the vacuum press in this case include depositing the film or veneer and ensuring their tight fit to the surface of the furniture structural element.

Vacuum pressing technology ensures fast and high-quality finishing of MDF

The principle by which a vacuum press works for veneering and covering furniture blanks with PVC film is quite simple. The heated film, which has become more plastic under the influence of the vacuum created under its surface, tightly fits the furniture piece, accurately repeating its configuration.

The film applied using vacuum technology to the surface of a piece of furniture made from MDF or chipboard lasts a very long time and does not contain even the smallest air bubbles.

The process of gluing a furniture element with PVC film using a vacuum press includes such technological operations as:

- laying furniture pieces on the equipment table;

- covering the workpieces with film and installing a pressure frame;

- sealing the vacuum chamber;

- heating the chamber and pumping air out of it;

- cooling of workpieces already covered with film;

- cutting the film along the contour of the blanks.

Liquid ring pump

Belongs to the category of low-vacuum pumping equipment. The design consists of a housing with plates installed inside. The plates are attached to the rotor. When the plates are immersed in a liquid (most often water), its volume changes.

During the operation of the equipment, conditions are created that are sufficient to ensure a 90-95 percent vacuum. To increase the indicator, you need to replace the water with another liquid that has a higher boiling point, and ensure cooling of the pumped air.

Among the advantages of such a vacuum pump, it is necessary to highlight its high service life, ensured by the absence of rubbing seals and the extreme simplicity of the design.

But the water ring unit also has a number of disadvantages, namely:

- the need to organize the collection and recycling or recycling of lost working fluid with the inclusion of waste gases;

- the need to regularly replenish the volume of working fluid in the equipment;

- the need to ensure cooling of the liquid used to reduce the pressure of the resulting vapors.

Assembling a liquid ring vacuum pump takes just a few simple steps.

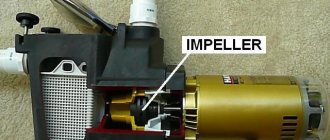

Vacuum pump part

First step. Prepare an appropriately sized enclosure. The pump body must be cylindrical.

Second step. Place the shaft with the impeller attached inside the housing. The wheel should be equipped with relatively small blades.

Third step. Ensure the supply of working fluid to the pump housing. The liquid must be supplied so that the blades rotate under its influence. The generated centrifugal force will force the liquid to flow towards the walls of the housing, and a vacuum will be created in the center of the device.

Such pumps are usually used in agriculture and manufacturing; in a city apartment they are unlikely to be of any use, but the owner of a private house may find such a unit useful.

Vodokoltsevaya

Find out how to choose the right pumping station, and also familiarize yourself with the nuances of the equipment from our new article.

Two-stage vacuum pumps ROAIRVAC 1.5 /3.0/6.0/9.0 R17300416 ROTHENBERGER (Roairvac)

Two-stage vane vacuum pumps for evacuation according to DIN 8975 with vacuum gauge and magnetic check valve.

- Non-return magnetic valve to protect the circulation system from oil contamination in case of power outages;

- A vacuum gauge with a built-in indicator needle allows you to easily and quickly monitor the draining process;

- Lightweight, durable housing protects internal parts;

- Gas ballast valve to reduce water vapor in the oil tank;

- A special filter reduces oil mist on the exhaust pipe;

- The oil level is controlled through the inspection window;

- Quick filling of oil without spilling, no special neck required;

- The drain plug is easily accessible for easy draining;

- Thermal switch protects the engine from overheating;

- Standard 1/4″ SAE connection, 5/16″ SAE and 3/8″ SAE adapters included;

- Detachable cable (to prevent damage).

- MODELS

- Advantages

- Documentation

- Gas ballast valve - reduction of water vapor in the oil tank, trouble-free pumping of compressed gases;

- Ergonomic handle - light, compact, easy to transport;

- Special filter - reduction of oil mist on the exhaust pipe;

- Detachable cable - prevents damage;

- Built-in pressure gauge - simple and quick control over the system draining process;

- Lightweight, durable housing - protects internal parts;

- Built-in magnetic valve - prevents oil from flowing back into the circulation system;

- 4-polar motor increased torque and long service life (Only for ROAIRVAC 1.5 and 3.0);

- Standard 1/4″ SAE connection with adapters for 5/16″ SAE and 3/8″ SAE;

- The best positioned sight glass and oil drain pipe make draining the oil convenient;

- Practical: operating instructions are always in front of your eyes.

Recommended equipment:

Mark the required items by checking the appropriate box

Delivery to all cities of Russia

Moscow St. Petersburg Novosibirsk Ekaterinburg Nizhny Novgorod Samara Omsk Kazan Chelyabinsk Rostov-on-Don Ufa Perm Volgograd Krasnoyarsk Voronezh Saratov Krasnodar Tolyatti Barnaul Izhevsk Ulyanovsk Yaroslavl Vladivostok Khabarovsk Irkutsk Novokuznetsk Tyumen Orenburg Kemerovo Ryazan Penza Embankment ny Chelny Tula Lipetsk Astrakhan Tomsk Makhachkala Kirov Cheboksary Kaliningrad Bryansk Magnitogorsk Ivanovo Kursk Nizhny Tagil Stavropol Arkhangelsk Belgorod Ulan-Ude Vladimir Sochi Kaluga Kurgan Orel Murmansk Smolensk Vladikavkaz Cherepovets Volzhsky Chita Saransk Surgut Vologda Tambov Kostroma Kostroma Komsomolsk-on-Amur Nalchik Petrozavodsk Sterlitamak Taganrog Bratsk Dzerzhinsk Yoshkar-Ola Orsk Mines Yakutsk Hangar SK Nizhnevartovsk Novorossiysk Syktyvkar Nizhnekamsk Biysk Grozny Stary Oskol Prokopyevsk Rybinsk Norilsk Blagoveshchensk Engels Balakovo Petropavlovsk-Kamchatsky Pskov Severodvinsk Armavir Zlatoust Balashikha Kamensk-Uralsky Khimki Syzran Podolsk Novocherkassk Korolev Yuzhno-Sakhalinsk Volgodonsk Nakhodka Berezniki Abakan Mytishchi Lyubertsy Rubtsovsk Maykop Salavat Ussuriysk Mia ss Kovrov Kolomna Elektrostal Almetyevsk Pyatigorsk Kopeysk Pervouralsk Nazran Odintsovo Nevinnomyssk Kislovodsk Dimitrovgrad Novomoskovsk Novocheboksarsk Khasavyurt Serpukhov Orekhovo-Zuevo Murom Kamyshin Zheleznodorozhny Neftekamsk Novy Urengoy Cherkessk Noginsk Novoshakhtinsk Nefteyugansk Shchelkovo Yelets Achinsk Novokuibyshevsk Sergiev Posad Noyabrsk Kyzyl Oktyabrsky Derbent Seversk Leninsk-Kuznetsky Arzamas Obninsk Between Rechensk Ukhta Kiselevsk Novotroitsk Bataysk Elista Artem Zhukovsky Velikiye Luki Kansk Magadan Tobolsk Abramtsevo Alabino Aprelevka Arkhangelskoye Ashitkovo Baikonur Baksheevo Barybino Beloomut White Pillars Borodino Bronnitsy Bykovo Valuevo Verbilki Vereya Vidnoye Vnukovo Leader of the Proletariat Volokolamsk Voronovo Voskresensk East Vostryakovo Vysokovsk Golitsino Dedenevo Dedovsk Dmitrov Dolgoprudny Domodedovo Dorokhovo Drezna Dubki Dubna Egoryevsk Zhilevo Zagorsk Zagorya Zaprudnaya Zaraysk Zvenigorod Zelenograd Ivanteevka Iksha Ilyinsky Istra Kashira Kerva Klimovsk Klin Klyazma Kozhino Kokoshkino Kolyubakino Kosino Kotelniki Kraskovo Krasnoarmeysk Krasnogorsk Krasnozavodsk Krasnoznamensk Krasny Tkach Kryukovo Kubinka Kupavna Kurovskoye Forest Town Likino-Dulevo Lobnya Lopatinsky Losino-Petrovsky Lotoshino Lukino Lukhovitsy Lytkarino Lvovsky Malakhovka Mikhailovskoye Mikhnevo Mozhaisk Monino Mukhanovo Narofomin sk Nakhabino Nekrasovka Nemchinovka Novobrattsevsky Novopodrezkovo Obukhovo Necklace Lakes Opalikha Pavlovsky Posad Pervomaisky Sands Pirogovsky Polushkino Pravdinsky Privokzalny Proletarsky Protvino Pushkino Pushchino Radovitsky Ramenskoye Reutov Reshetnikovo Springs Roshal Rublevo Ruza Saltykovka Northern Silver Ponds Solnechnogorsk Solntsevo Sofrino Staraya Kupavna Starbeevo Stupino Skhodnya Taldom Tekstilshchik Tempy Tishkovo Tomilino Troitsk Tugolessky Bor Tuchkovo Uvarovka U efficient Uspenskoe Firsanovka Phosphorite Fryazino Fryanovo Khorlovo Khotkovo Cherkizovo Chernogolovka Cherusti Chekhov Sharapovo Shatura Shaturtorf Shakhovskaya Sheremetyevsky Shcherbinka Elektrogorsk Elektrougli Yakhroma Alexandrovskaya Boksitogorsk Bolshaya Izhora Budogoshch Ascension Volosovo Volkhov Vsevolozhsk Vyborg Vyritsa Vysotsk Gatchina Druzhnaya Gorka Dubrovka Efimovsky Zelenogorsk Ivangorod Kamennogorsk Kikerino Kingisepp Kirishi Kirovsk Kobrinskoe Kolpino Communard Kronstadt Lisiy Nos Lodeynoye Pole Lomonosov Meadows Pavlovsk Pargolovo

Using a refrigeration compressor

An old compressor from a refrigerator can be used to work as a vacuum pump; the main requirement is its functionality. A self-made vacuum pump can continue to function both as a supercharger and as a vacuum device. Before assembly, you will need several elements that can be found in the disassembly:

- the frame on which all the parts will be attached is made from angles by welding or bolting;

- a small freon or propane cylinder can be used as a receiver;

- pressure gauge;

- connection hoses;

- moisture separating filter;

- machine and wires;

- crosspiece acting as a collector.

DIY vacuum pump from a compressor from a refrigerator

In the case of building a universal design, it is worth providing a pressure switch that turns off the supercharger when it reaches a certain level. Before assembly, used oil is removed and new oil is added to extend the life of the device. The assembly order is as follows:

- A compressor with a receiver is screwed to the frame, the supercharger is installed in a vertical position, and anti-vibration material or cushions are used.

- All parts and the filter are connected with hoses.

- Installation of the power supply is carried out with the obligatory inclusion of the circuit breaker in order to avoid damage due to a short circuit.

When a compressor is needed, the hoses are simply swapped. The universal design allows the device to be used in many directions.

Application of receivers

The operation of primitive instruments does not require the system to maintain constant pressure. A manual vacuum pump for pumping out air is only effective during the piston stroke, which causes surges.

Receiver from a gas cylinder

When performing precise actions, no breaks are allowed; a receiver is used for this.

The principle of operation of the receiver is to maintain a buffer state during pressure surges; an old gas cylinder can be used as a device.

The device is connected in series, equipped with a pressure gauge, the calculation is made in accordance with the material and capacity. The use of a vacuum receiver can be done with a regular glass bottle.

Features of operation

Vacuum pumps are designed to create a vacuum space in separate volumes. It is used for household purposes, automotive industry, and production. Operating a DIY device can significantly reduce the time it takes to pump out gas.

A vacuum blower is not the first household device; most people use a regular vacuum cleaner. However, there are tasks that cannot be completed without a special device. Having a device will help you complete most tasks yourself, without resorting to the help of specialists.

Indications for mini-abortion

There are no special indications for a mini-abortion; the leading and sufficient indication is the woman’s desire to terminate the pregnancy. But there are also medical indications for early termination of pregnancy. Vacuum aspiration is indicated:

- during frozen pregnancy;

- with anembryonia;

- if bearing a fetus poses a threat to a woman’s health and life (diabetes mellitus, severe liver and kidney pathologies, malignant tumors, etc.);

- with rubella, influenza and other infections during pregnancy;

- social indications (for rape, being in prison, etc.);

- if necessary, endometrial biopsy;

- if remnants of the fertilized egg are found in the uterus after a pharmacological or surgical abortion;

- when parts of the placenta are retained after childbirth or cesarean section;

- for menstrual irregularities (bleeding);

- with accumulation of blood (hematometra) or serous fluid (serozometra) in the uterine cavity;

- with incomplete spontaneous abortion.