A little about lithium-ion batteries

These include the following aspects:

- high density of output current and accumulated energy, long-term charge retention;

- no effect of capacity reduction due to regular incomplete charging;

- self-discharge no more than 4-8% per month when stored without recharging, aging no more than 15-20% per year;

- no need for a full discharge to train the energy capacity of the drive;

- light weight, variability of shape and dimensions of the device;

- operating temperature range – from -20°С to +50°С (low temperatures prevent recharging);

- long service life (up to 10 years of operation and more than 1000 discharge cycles).

The disadvantages of lithium batteries are:

- dependence of the service life on the duration of use and storage, and not on the number of discharge cycles;

- risk of failure during overcharging (current flow upon completion of charging);

- low resistance to deep discharge;

- high price;

- explosion hazard due to mechanical damage and excess current, if they lead to heating of the electrolyte and breaking the seal of the housing.

The name of the 18650 battery is due to its shape and dimensions. The battery width is 18 mm and the length is 65 mm. The last number in the marking indicates the cylindrical shape of the battery. The drive circuit is equipped with a controller that prevents overheating during charging.

The battery case can be marked in more detail: for example, INR18650-20R. The first letter distinguishes all lithium-type batteries, the second specifies the type of cathode material (C – cobalt, N – manganese, F – ferrophosphate).

The letter "R" stands for rechargeable. The next 5 digits reflect the dimensions and shape factor of the battery, and the last one is the battery capacity in Ah.

18650 batteries with a protection board can be labeled as 18700 or 18670. The protection board controller helps prevent the battery voltage from exceeding the rated voltage (4.2 V) and falling below 2.5 V.

Preparation

To create a charger for a 18650 battery with your own hands, you will need:

- a module based on the TP4056 chip, namely a version with a protection circuit - for monitoring voltage using the DW01A and FS8205A components;

- power supply with a voltage of 12 V and a current of 2 A;

- SPST switch with 2 terminals;

- 5 V power supply or instead a 7805 stabilizer and 4 100 nF capacitors;

- compartment for a cylindrical Li-ion element with standard parameters 18x65 mm;

- printed circuit board;

- power connector;

- soldering iron for assembling elements according to the diagram;

- plastic box with approximate dimensions 8 cm x 7 cm x 3 cm;

- glue for fixing components;

- hot knife for cutting plastic;

- screws, screwdriver for screwing the lid.

How to charge lithium-ion batteries yourself

The simplest option is to use a mobile phone charger. The devices produce a voltage suitable for restoring the power of 18650 batteries. The method is used only in emergency cases. Its frequent use leads to a decrease in battery capacity.

Homemade charger for a lithium-ion 18650 battery, made from an old phone charger.

To charge the battery, do the following:

- The charger plug is cut off. The wires are stripped of insulation and divided into positive and negative poles. The positive cable most often has a red braid, and the negative cable has a black braid.

- The cleaned wires are attached to the battery poles with plasticine. The USB cable is connected to a computer connector or a special adapter.

- The power source is charged, periodically monitoring the process. It is recommended to charge the battery for no more than an hour. This time is enough to completely restore capacity.

Complex circuits are used to assemble advanced charging. Before starting work, prepare a soldering iron, solder, flux and glue. Separately, purchase the board necessary for the normal functioning of the homemade charger.

https://youtube.com/watch?v=2wMnrZpl3Vo

The assembly is carried out like this:

- The board is installed in a plastic box prepared in advance. The structure is supplied with positive and negative wires. The box is used to hold the battery while charging. You can make a container from an old charger, an unusable household appliance or a toy. The dimensions must match the battery parameters.

- The board is soldered, taking into account the markings. The markings make it easy to place the wires. The board is equipped with multi-colored indicators that reflect the charging progress. The microcircuit is glued to the box in a convenient place. After this, observing the polarity, connect the wires. Before fixing, they are cleared of insulation and treated with rosin. A small amount of liquid solder is applied to the board.

During the manufacture of the device, short circuits must not be allowed. The above diagram allows you to assemble a simple but reliable charger in a few hours. Using a USB cable, it is connected to an electrical outlet or computer. The battery is installed in the resulting socket. After the green indicator turns on, the device is turned off.

Recommendations from experts

Experts recommend taking a responsible approach to the process of charging and discharging the battery. Its durability depends on this. It is not worth discharging the battery completely and charging it to 100%. It is better to limit the charging process to 90%. However, periodically (every three months) you can completely discharge and fully charge the battery. This is necessary to calibrate the controller.

The battery can be stored for quite a long time. To do this, you need to charge it 50%. She can remain in this state for about a month. At the same time, the room should not be too hot or too cold. Ideal conditions are considered to be keeping the temperature at 15 ºС.

By looking at how to charge a 18650 battery, you can properly maintain and operate the battery. In this case, its service life will be much longer.

Which device should you use?

Different models of chargers differ in technical characteristics, set of functions and some other parameters:

Liitokala Lii-500 is a universal charger that automatically selects currents for.

- Simple. Such devices supply a current of 1 A. They have a single socket for installing an 18650 battery.

- Improved. The device is equipped with 2 battery slots. The maximum voltage level is 4.2 V. This charger is more expensive. Additional functions include charge indication. The device automatically limits the procedure time, preventing overcharging.

- Universal. Used to charge power supplies of the 18650 and 26650 types. Models of this type are used to restore the functionality of lithium-ion and nickel-cadmium cells. The best devices are equipped with a safety system that eliminates the need for regular voltage and current measurements.

- Homemade. If a ready-made device cannot be found, the charger can be assembled at home. The components are connected according to the diagrams.

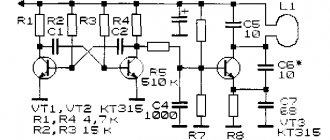

Homemade charger at home (with your own hands) - 1 circuit

To charge the 18650, purchase a universal charger and constantly use a multimeter to find out the necessary parameters. But such a device is quite expensive. Minimum price – 2700 rubles.

Instead, you can spend just a few hours and assemble the charger yourself. The advantages of this assembly are low cost, reliability, and automatic battery shutdown. All the parts used for assembly can be found in any radio amateur's garage. If something is missing, you can buy it at the nearest radio store. You will have to spend a maximum of 300 rubles on components.

If the circuit is assembled correctly, there is no need for additional configuration - it will be immediately ready for use.

You need to use the following electrical diagram:

Scheme

The positive point is that if you install the stabilizer on the desired radiator, then the battery is charged without fear that the charger will catch fire. But this certainly cannot be said about Chinese chargers, which suffer from this unpleasant consequence.

A little about lithium-ion batteries

Features of 18650 battery:

- Long service life. The power supply can withstand up to 600 discharge and charge cycles. Lithium batteries have an extended service life and can retain capacity for a long time.

- Compact sizes. The height of the element is 65 mm, diameter is 18 mm. These numbers formed the basis for the name of the battery. Despite its small size, the battery has ample capabilities.

- Availability of a controller. Most old-style batteries are highly explosive. Chemical reactions take place in the battery case, the speed of which increases many times over when overheated. A mechanical short circuit of several containers containing electrolyte also occurred, leading to a fire. The controller, built into modern power supplies, prevents severe overheating and explosion. It's from overcharging.

- Impossibility of long-term storage. Batteries left unused for a long time quickly lose capacity. Li-ion batteries need to be charged regularly. At the same time, a number of rules are observed to prevent the product from failure. It is necessary to correctly calculate the charge current and limit the voltage. Violation of the rules leads to a decrease in service life.

Features of lithium batteries

Li-ion batteries are very unpretentious to use. If handled with care, they will last about 3-4 years. However, it is worth focusing on the fact that even if batteries are not used, they slowly die. Therefore, stocking up on batteries for the device for future use is not entirely reasonable. 2 years is the normal time from the date of production. If more has passed, then these may be already failed batteries.

Interesting. The most common 18650 can size has an average capacity of 3500 mAh. The normal price for such a battery is 3-4 dollars. Therefore, manufacturers who promise a 10,000 mAh Power bank for $3 are, to put it mildly, deceiving. It would be good if there was at least 3000 mAh.

Which device should you use?

To recharge the 18650 battery, you need to use devices with a rated voltage of 4.2 V. If the lithium-ion drive is planned to be connected to a universal charger, then it must be equipped with a parameter controller and indicators for the end of the process.

The cheapest models have 1-2 slots for batteries, a maximum amperage of up to 1 A and a nominal voltage of 4.2 V. The best charger option for lithium drives is a smart device equipped with a terminal voltage meter, a recovery function after a deep discharge and protection against exceeding the nominal voltage

What is the difference between a charge controller and a protection circuit?

Some users periodically have a question, put in the title of the section - why do we need a charge controller if there is a protection circuit (individual or general in the form of a balancing board). The fact is that these devices solve different problems :

- the protective module protects the element from overcharging, prevents it from going into a deep discharge, and turns off the battery when the permissible temperature is exceeded;

- The charge controller forms the correct mode of energy replenishment - stabilizes the current at a given level, carries out additional charging according to various algorithms.

And confusion may arise due to the fact that there are cases when some of the functions of these devices are duplicated. Thus, overheating protection can be built into both the protection board and the charge controller. And both the built-in board (disabling the battery) and the charger (completing the process of replenishing energy) can protect against overcharging.

How to charge a 18650 battery

Many chargers (chargers) are universal, but when charging lithium-ion batteries you must follow these rules:

0.5-1 A is the optimal charge current for 18650 batteries.

- At the early stage, it is necessary to apply no more than 0.05 V. Finish the procedure by increasing the parameter to 4.2 V. This value is an acceptable safe level for 18650 batteries.

- The charge current should be 0.5-1 A. With a higher value, the charge will be collected faster. However, it is not recommended to immediately supply a current of 1 A. The indicator should increase smoothly.

- Accelerated charging methods should only be used in emergency cases. The procedure time should not exceed 3 hours. Overcharging damages battery components, causing overheating.

- It is recommended to use devices that automatically monitor charging progress. They turn off automatically after the battery reaches the required power. Cheap and homemade devices are not equipped with controllers, so the user will have to independently monitor the progress of the procedure.

Charging options

Both in series and parallel connections, the charging and discharging currents must be observed. If the battery is lithium, the charging current should not be more than half the energy capacity, measured in Amperes. For example, a 1000 mAh model (1 Ah) - the current is set to 0.5 A; 2 Ah – 1 A.

The maximum discharge currents are indicated in the battery characteristics. Many models for smartphones and laptops do not allow currents that are twice the energy capacity of the battery. Let's say the battery is 2500 mAh, the limit for it is 5 A (2.5 x 2). However, high-current devices are now being produced.

Useful tips for using 18650 batteries

To preserve battery capacity and extend their service life, you need to follow several tips:

- correctly select the operating mode of the charger, and in the absence of a controller, adjust the parameters automatically;

- avoid deep discharge, connect the battery when the charge drops to 70-80%;

- when calculating the recovery duration, take into account not only the number of ampere hours, but also the difference in voltage when charging in a factory and at home, which affects the watt capacity;

- do not try to increase the battery capacity by discharge-charge cycles;

- do not allow the drive to overheat, do not leave it in direct sunlight;

- operate the battery at a temperature of +10…+25°С; for use at low temperatures, insulate the case;

- Avoid impacts on the body of the battery, exposure to strong friction and vibration; during transportation, place batteries on a thick soft substrate;

- store lithium-ion drives with 50-60% charge and at a temperature of about 0°C.

When purchasing a battery, you need to pay attention to the release date. Batteries manufactured more than 3 years ago are considered expired and low-functional.

It is also important to know 3 nuances about “life extension” 18650

- If the battery needs to be left unused for some time, it is advisable to store the batteries separately from the device that they will power. If a cell is fully charged, it will lose some of its charge over time. In the case when the element is charged very little, or is completely discharged, its performance may completely disappear. This is especially noticeable during periods of long hibernation.

- The 18650 should be stored at a charge level that does not fall below 50%. Under no circumstances should the cell be allowed to be fully charged or overcharged. This equipment has no memory effect. Charging must be done until the charge is completely exhausted. This will extend the battery life.

- The battery must not be left in extremely cold or hot areas. Suitable storage temperature is + 10 - + 25 degrees Celsius. If you place the battery in the cold, not only will the operating time decrease, but the chemical system will also deteriorate. Everyone has probably noticed that when using a mobile phone in winter, the battery charge drops sharply.

How to charge a 18650 battery

When charging a 18650 battery, the following rules must be observed:

- Recovery should begin at a voltage of 0.05 V, gradually increasing it to 4.2 V.

- The range of permissible charge current is 25-50% of the capacity (for example, for a 2000 mAh battery it varies from 0.5 to 1 A).

- The optimal figure is 25-30% of the capacity, the maximum amperage is used only for urgent recharging.

- The permissible charging time when the battery is completely discharged is 3 hours.

- To accurately select the recovery duration, you need to measure its voltage with a multimeter or connect it to an intelligent charger.

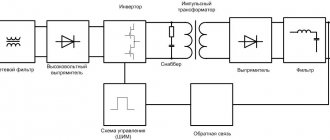

The optimal mode consists of two stages:

- CC (constant current). It needs to provide a constant amperage, which is within 20-50% of the battery capacity. With accelerated charging, a higher current value can be used, but it is not recommended to use this mode often. The charger must be equipped with a smooth voltage rise function. At the first stage, the charger works as a current stabilizer.

- CV (constant voltage). When the voltage rises to 4.2 V, you can proceed to the second stage of recharging, at which a voltage of 4.15-4.25 V is maintained. By the end of the first stage, the battery is restored by 70-80%. As the charge accumulates to 90-95%, the amperage will gradually decrease. As soon as its value reaches 1-5% of capacity, the battery can be disconnected from the charger.

Some “charger” models are equipped with a battery recovery mode for deep discharge (less than 2.5 V). The battery is charged with low current (no more than 5-10% of capacity) until its voltage reaches 2.8 V. After this, the charger switches to direct current mode.

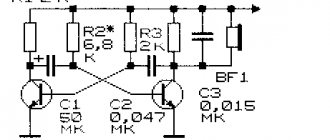

Homemade lithium battery charging - electrical diagram

The basis for this device are two stabilizer microcircuits 317 and 431 (forum topic). In this case, the LM317 integrated stabilizer serves as a current source; we take this part in the TO-220 housing and must install it on the heat sink using thermal paste. The TL431 voltage regulator manufactured by Texas Instruments is also available in SOT-89, TO-92, SOP-8, SOT-23, SOT-25 and other packages.

Recommended input voltage is from nine to twenty volts. The output is adjusted with a 22 kOhm trimmer; it should be around 4.2V.

Light emitting diodes (LED) D1 and D2 of any color you like. I chose the following: LED1 red rectangular 2.5 mm (2.5 milCandelas) and LED2 green diffusion 3 mm (40-80 milCandelas). It is convenient to use SMD LEDs if you do not install the finished board in the case.

The minimum power of resistor R2 (22 Ohm) is 2 Watts, and R5 (11 Ohm) is 1 Watt. All other ones are 0.125-0.25W.

The 22 kiloOhm variable resistor must be of type SP5-2 (imported 3296W). Such variable resistors have very precise resistance adjustment, which can be smoothly adjusted by twisting a worm pair similar to a bronze bolt.

What are lithium batteries?

Depending on what material the positive electrode of a lithium battery is made of, there are several varieties:

All of these batteries have their own characteristics, but since these nuances are not of fundamental importance for the general consumer, they will not be considered in this article.

Also, all li-ion batteries are produced in various sizes and form factors. They can be either cased (for example, the popular 18650 today) or laminated or prismatic (gel-polymer batteries). The latter are hermetically sealed bags made of a special film, which contain electrodes and electrode mass.

The most common sizes of li-ion batteries are shown in the table below (all of them have a nominal voltage of 3.7 volts):

| Designation | Standard size | Similar size |

| XXYY0 , where XX is the diameter in mm, YY is the length in mm, reflects the design in the form of a cylinder | 10180 | 2/5 AAA |

| 10220 | 1/2 AAA (Ø corresponds to AAA, but half the length) | |

| 10280 | ||

| 10430 | AAA | |

| 10440 | AAA | |

| 14250 | 1/2 AA | |

| 14270 | Ø AA, length CR2 | |

| 14430 | Ø 14 mm (same as AA), but shorter length | |

| 14500 | AA | |

| 14670 | ||

| 15266, 15270 | CR2 | |

| 16340 | CR123 | |

| 17500 | 150S/300S | |

| 17670 | 2xCR123 (or 168S/600S) | |

| 18350 | ||

| 18490 | ||

| 18500 | 2xCR123 (or 150A/300P) | |

| 18650 | 2xCR123 (or 168A/600P) | |

| 18700 | ||

| 22650 | ||

| 25500 | ||

| 26500 | WITH | |

| 26650 | ||

| 32650 | ||

| 33600 | D | |

| 42120 |

Internal electrochemical processes proceed in the same way and do not depend on the form factor and design of the battery, so everything said below applies equally to all lithium batteries.