A lift for a router, which can be purchased in a serial version or made by hand, is a device that allows you to improve both the quality and accuracy of processing performed with hand-held power tools.

The results of the latter strongly depend on how accurately and confidently the user manipulates such a device.

In order to minimize the influence of the human factor on the results of processing performed with a manual milling cutter, special devices were developed.

Homemade elevator for a manual router, made of plywood and timber

One of them is a mechanized lifting device for milling power tools, which, in full accordance with its functionality, is called an elevator. As mentioned above, such a device can be purchased in a serial version, but it will not be cheap, so many home craftsmen successfully make it with their own hands.

milling table and lift for the router

To get a professional result you need a router table and a lift, router, bit and they don't have to cost a fortune or weigh a ton. My version of the milling table is 25 mm thick plywood, which does not require a cabinet or cabinets below and is attached to the workbench with clamps. The project has an adjustable lift and a stop with a dust collector.

How to make a router table and a router lift

Milling table and elevator, these are the first works on the milling table and they consist of preparing a place for the router and two metal rods for the elevator.

Notice in the photos that instead of mounting the router on removable plates, I use two metal guide rods that come standard with the tool. diameter of the rods. Having installed the router in the grooves on the table, secure it to the table using mounting blocks: bolt, washers and nuts

If your router does not have guide rods, then you will need to make changes to the attachment of the router to the base

diameter of the rods. Having installed the router in the grooves on the table, secure it to the table using mounting blocks: bolt, washers and nuts. If your router does not have guide rods, then you will need to make changes to how the router is attached to the base.

Assembling the router lift

The router lift consists of an open frame mounted on one of the mounting blocks. A nut is installed on the frame through which the threaded rod rotates using a round disk (Fig. 5,6). The manufacture of the elevator begins with the manufacture of the frame and (positions 3, 4, 5, 6 and 10) (Fig. 4). In order to prevent rotation of the elevator clamping bar (Fig.7)

around the router (position 10) (Fig. 4), four screws are screwed into the upper part of the router and they are aligned with the holes in the elevator clamping bar.

Creating a stop

Making the stop is not difficult. Prepare the vertical and horizontal bases (positions 11 and 12) (Fig. 4). Using a drill, jigsaw or router, form slots in the bases (Fig. 9). Make four triangular strips (item 13) (Fig. 4) to stiffen the stop.

You are ready to assemble the stop, connect the prepared parts together (Fig. 11). The ends of the auxiliary pads (item 14) (Fig. 4) for the stop, cut at an angle of 45°. Drill through holes for bolts in each trim.

note

Install the pads on the vertical support base and secure with bolts, washers and nuts (item 17) (Fig. 4). And lastly, the dust collector (position 15) (Fig. 4) is needed or not - it’s up to you to decide. Cut it to size, bevel the ends for a tighter fit.

Cut a hole in the dust collector bar that matches the diameter of the hose nozzle. Connect the dust collector bar and the stop using the curtain (position 16) (Fig. 4).

At the final stage

Many people write that for precision machining, each cutter must use a hole corresponding to the diameter of the cutter. A large diameter cutter is used, which means it requires a large hole in the base of the table.

If desired, make insert rings of different diameters, although these rings are optional and you can work with one large hole drilled in the base of the table (Fig. 4). Basically, in a hole with a diameter of 32 mm. will accommodate cutters of different diameters.

I note that in the process of processing products without insert rings, no large flaws were noticed that could not be eliminated with sandpaper. At the final stage, carefully sand the parts and apply several layers of durable coating.

How to make a lift for a router in a workshop

The author makes a milling table from wooden blocks and a sheet of plywood. You need to cut a rectangular hole in the center and also make a lid with a round hole.

Main stages of work

From pieces of ordinary plywood, cut to size and furniture guides, the author assembles the main part of the lift for the router. You will also need a piece of threaded rod (or a screw of the appropriate diameter).

Next, you will need to cut another rectangular blank from laminated plywood with a hole for the back of the router. Then we take two cables and we can begin assembling the lifting mechanism.

At the last stage, the entire structure and a manual router are installed under the table. The result is a simple elevator that will help make work more comfortable.

Source: https://sdelairukami.ru/kak-sdelat-podemnik-dlya-frezera-v-masterskoj/

How to choose a practical option

Technology for making cabinet furniture with your own hands

There are different ways to make a homemade milling table, but the design principles of most models are the same.

First, choose one of 3 types of milling installation, which determines the dimensions and location of this equipment in the carpentry workshop:

- Mounted. A separate aggregate unit, which is attached to the sawing machine on the side using clamps. Allows you to use the working surface of other equipment, can be easily removed, and put aside with your own hands when not needed.

- Portable. A desktop modification that is sought to be made with the minimum required dimensions of the bed and milling table. An efficient machine to use when frequently moving around construction sites.

- Stationary. The main type of table for established production, provided there is sufficient space in the room. This is no longer just a milling cutter, but an equipped workplace.

DIY materials

The working plane of the table ensures smooth sliding of the workpiece in one plane. Laminated chipboard and MDF sheets cope well with this task. To prevent the tabletop from bending under the weight of the router, take a slab with a cross section of 2.6/3.6 cm. For the side parts, a sheet of chipboard with a thickness of 1.6 cm or more is sufficient.

The mounting plate on which a massive router is attached, by definition, has high strength and rigidity. Sheet materials suitable for it are metal, textolite, and hardwood plywood. The thickness of the plate does not exceed 0.8 cm.

The load-bearing support of the table is made with your own hands from a metal profile or sheet chipboard. Sometimes these are just legs with elements of rigidity, in other cases the table includes front-mounted drawers for tools, small equipment, and utility devices.

The main part - the milling cutter - is purchased from industrial production.

Additional devices

The creative use of additional equipment in the design of a homemade milling table can significantly expand its functionality. You can achieve smooth adjustment of the height of the cutting part above the plate if you make a lift for the working tool with your own hands. For this purpose, the vertical axis of the assembly rests on a screw with a fine rectangular thread passing through a fixed nut. Rotating the flywheel on the rod regulates the feed of the cutter. The mechanism is equipped with side stops to prevent bending and a lock nut to hold it in a given position during vibration. If possible, they install more complex lifts - a car jack, a tailstock from a lathe.

Another addition is a steel ruler along the longitudinal axis of the guides of the workpiece. Practical, convenient, allows you to control the sample size, frees your hands for other operations.

Tool

To make all the details of the milling table with your own hands you will need:

- hacksaw, electric jigsaw;

- emery, grinding machine;

- electric planer;

- drill;

- chisel;

- screwdriver, screwdriver.

The use of electro-mechanical tools speeds up work on the manufacture of table tops, guides, oblique stops, but, if necessary, operations can be performed with your own hands and hand tools.

Lift for router

DIY fiberglass bumper - manufacturing methods

Every craftsman who works with wood knows how inconvenient it is and how many unnecessary actions have to be performed to set the desired cutter height when working with a hand router, or to replace one cutter with another. To do this, you even have to remove the router from the table.

In order to significantly facilitate this task, a special device called a milling elevator was invented long ago, which is, in fact, the “third hand of the master” that helps regulate this process.

Currently, there are a large number of different models of milling elevators on sale. The best elevators are made in the USA and are quite expensive.

Not long ago, in one of the woodworking magazines, the design of a homemade elevator designed for a hand router was shown. This design will allow you to quite accurately adjust the height of the cutter, and making it yourself will not be difficult for a good craftsman. In addition, there is a detailed photo with a detailed description of the entire process of manufacturing such a model.

General concept and principle of operation

An elevator or hoist is a special device for a router that is installed in the workbench. The main task is to relieve the master from the need to continuously hold an almost 5-kilogram machine in his hands while working. The lift raises the milling tool to the required working height, holds it as long as required, and moves it in a horizontal plane. This has a positive effect on the accuracy of workpiece processing.

The up and down movement of the router is controlled by a lever or other lifting mechanism provided by the design of the router elevator. Due to this, it is possible not only to mark the exact dimensions of the grooves on the workpieces, but also, if necessary, to quickly replace one router with another.

The operating procedure of the milling elevator mechanism is as follows:

- A support plate for a sheet metal router or textolite is installed on the workbench.

- Two racks are installed and secured on the plate parallel to each other.

- The milling machine is mounted on a special movable carriage that can move up and down along the supports of the support plate.

- The carriage with the router and the entire lifting mechanism are moved to the required distance by the action of the pushing device.

Homemade table

Car strobe light is a simple circuit for DIY assembly. powerful strobe with your own hands, how to make a strobe with your own hands using simple spare parts

The most primitive drawing of a homemade table for a router is an MDF table top, in which a hole is made for the router to pass through and a guide ruler is attached - an evenly planed board. This tabletop can be placed between two workbenches or installed on its own legs. Its advantages are the simplest and quickly manufactured design. Such a device is unlikely to allow you to carry out serious woodworking. Let's consider more functional options, including a rotary one.

Small router table

neat and small table

A tabletop model for a hand router, which you can make yourself in a few evenings. The design is light and mobile, fits on a shelf, takes up little space, and its drawings are simple.

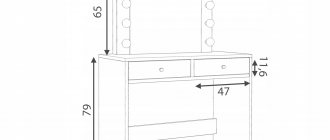

- The working surface and side racks are made of thick laminated plywood No. 15. The size of the table top is 40 x 60 cm, the height without the corner stop is 35 cm, the height of the stop is 10 cm. Three grooves are selected in the surface of the work table for installing rails. Various auxiliary devices are installed here and moved along the tabletop.

- To make the structure stable, the legs are made of chipboard or MDF No. 22. The legs are placed with a slight indentation, leaving a little space for attaching templates and clamps using clamps.

- To cover the mechanism, a front panel made of plywood or chipboard is installed below.

- The side stop has grooves along which it moves. Locked in the right place using bolts and wing nuts. The emphasis can be dismantled and any convenient device can be installed in the free space.

- A pipe is connected to the stop to remove chips that are released in abundance during operation. The chip drains of the router and the table are connected through plastic corrugations from the sewer siphons by a splitter for the water supply. A hose from a household vacuum cleaner is attached to a clamp. The result is a very effective system for removing chips; they practically do not scatter throughout the room.

- Since the machine is designed for a manual milling machine, a special on/off switch is not required.

- The stop consists of two parts, which are moved closer or further depending on the diameter of the working body. A wing nut is provided to secure the sash. The good thing about the proposed model is that the tool can be easily removed from the frame to replace the cutters.

- The mounting platform for the router is made of textolite or plexiglass. The plastic platform from the router kit is first dismantled. The recesses for the mounting area are selected with a router, and the hole is cut with a jigsaw. When the hole is ready, the plexiglass is adjusted to its size and shape. It should fit tightly and without protrusions into the window.

You can make several mounting platforms of the same size with holes for different cutter diameters.

This option is convenient for small hand tools. If a stationary table is being made for a large router, insert rings for different cutter diameters are attached to one mounting platform.

To ensure that the workpiece moves smoothly, motion stoppers are installed on the side stop. Clamps are also attached to the side stop, which hold the part near the cutter during operation. Additional convenience is provided by the slide, along which the workpiece moves at a right angle. And to make the work safe, pushers are manufactured.

The table is ready for use; its drawback is the lack of adjustment of the processing depth. This is done manually by pressing on the tool. It is impossible to “get” to the desired depth the first time. Therefore, we recommend equipping the table with a lift.

You need to make a hole in the frame into which an adjusting bolt with a wing nut is inserted. The depth of milling is smoothly changed by twisting the lamb.

Some craftsmen adapt old car jacks for a lift for a powerful router. The device is attached under the router; a hole is made in the side wall to bring the jack handle out. The jack handle can be bent at the desired angle; when rotated, the router smoothly moves up and down in 2 mm increments.

Another model of a homemade milling table for a router in the video:

Why is such a device needed?

A lift for a router, which ensures precise movement of a hand-held power tool mounted on it in a vertical plane, is necessary in many situations. Situations in which the quality and precision of processing of wood products are of no small importance include decorative finishing of furniture panels, making technological grooves and lugs on elements of furniture structures. The quality of processing in such cases will not depend on the experience of the master performing it and the firmness of his hands, but only on the accuracy of the device settings and the degree of its stability.

Even a person with good physical fitness gets tired when working with a hand router, the weight of which can be 5 kg or even more. This directly affects the accuracy and quality of work. In addition, the precision of processing that a manual milling machine mounted on an elevator can provide cannot be achieved when manipulating a power tool manually.

For most routers, standard adjustment when installing the tool in the table becomes simply inconvenient

The need to invent such a useful device as a lift for a router was driven by the fact that the variety of types of decorative finishing of wood products has expanded significantly, the technological methods for processing this material have become more complex, and the requirements for the accuracy of its implementation have also increased. All of the above factors require that manual milling electrical equipment combine high mobility of its working body, as well as the accuracy of the movements it makes. It is these requirements that are fully met by a lift for a router, with the help of which the power tool used is quickly raised and lowered to the required height above the workbench, and also held at a given level for the required amount of time.

The convenience of using a milling elevator also lies in the fact that it is not necessary to install a power tool on such a device each time. This helps to both simplify the production process and increase its productivity.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Table design

The simplest design of a milling table involves the presence of three main elements - a working surface or tabletop, a machine base or bed, and additional equipment - a limit bar, adjustment devices, and safety devices.

Among the device layout diagrams that can be found on the Internet, all designs can be divided into three types:

- Multifunctional free-standing devices for working and storing tools.

- Tabletop small-sized tables for milling, which are installed on a workbench or desktop.

- Tables are attachments that are attached to brackets or special seats to a workbench or desktop.

And if the former require a certain skill and skill for design and assembly, then desktop structures and milling attachments can be made independently from drawing development to practical implementation.

The basis of the table is the bed - a rigid structure on which the working surface of the milling table - the tabletop - is placed, there is a mount for installing the tool and equipment for fixing and adjusting it.

The entire structure is made of wood and lumber, held together with glue and screws to assemble the furniture. Structurally, a simple table for a router should be of a rigid and stable structure to dampen vibration and at the same time be lightweight so that it can be easily moved from place to place.

Manufacturing materials

The correct choice of table materials determines its service life and the quality of milling of parts. What materials are recommended to be used for these purposes?

Table. Types of tables by material of manufacture

| Type of table for a router | Brief description of physical and operational characteristics |

| Plywood | Most often used. In terms of cost and performance indicators, the most suitable option, you just need to buy special plywood, its veneer is glued with especially strong two-component polymer adhesives. This type of plywood is not recommended for use during furniture manufacturing; the amount of phenols and formaldehydes released into the air exceeds permissible standards. But in the workshop the material can be used without fear. But in terms of strength, this type of plywood confidently occupies a leading position, and this is the most important characteristic. |

| Metal | A metal table has been in use for many decades, but to manufacture it you must have practical experience in welding work. Another problem is that some parts need to be sharpened; almost no one has a lathe at home, so you have to turn to specialized companies. |

| Combined | Highly recommended for use. Some of the most loaded elements are made of metal, the rest can be wooden. By the way, the table does not have to be made from scratch - after a little reconstruction, ordinary prefabricated/collapsible small kitchen tables fit perfectly. These were once in every apartment and today are still used in utility rooms. |

You can also use glued furniture panels made from natural lamellas; they do not change their size with fluctuations in relative humidity, but such a table for a router will be very expensive. It is strictly forbidden to use natural boards due to constant warping in one direction or another, which has an extremely negative impact on the quality of milling.

A tabletop made of boards is not suitable for making a milling machine.

We will give step-by-step instructions for making two simple, but very functional, tables for a router. The dimensions are given only general, specific ones depend on the type of hand router, and there are a huge number of them in sale

Each model differs in several parameters that must be taken into account during work.

Scheme for assembling a table for a manual router. 1 — side strip for fastening with clamps on trestles; 2 - drawer; 3 — countersunk guide holes; 4 — front wall of the stop; 5 - self-tapping screw with countersunk head 4.5x42 mm; 6 - scarf; 7 - support base

Milling table design

If you wish, you can make a homemade milling table from a regular workbench, but it is better to make a special design. This is explained by the fact that a machine with a milling cutter creates strong vibration during operation, so the bed used to fix the milling cutter must be highly stable and reliable. It should also be taken into account that the milling device itself is attached to the bottom of the tabletop for the milling table, so there must be enough free space under it.

When attaching the device to the top of a homemade table for a manual router, a mounting plate is used, which must have high strength and rigidity, or special clamps for a milling machine. Such a plate can be made of metal sheet, textolite or durable plywood. The bases of most router models already have threaded holes; these are what are needed to connect such a device to the tabletop and mounting plate. If there are no such holes, you can drill them yourself and cut threads into them, or use special clamps for a milling machine.

Milling cutters for various types of processing on a milling table

The clamps for the milling machine or the mounting plate must be located at the same level as the tabletop; for this purpose, the latter is sampled with the appropriate dimensions. It is necessary to drill several holes in the plate, some of which are necessary to connect it to the tabletop using self-tapping screws, and others so that such a plate can be fixed to the base of the router. The screws and self-tapping screws that you will use must have a countersunk head.

To make turning on your device more convenient, you can place a regular button on the tabletop, as well as a mushroom button, which will make your device safer in operation. To increase the convenience of your home machine, you can attach a long metal ruler to the surface of a milling table made for a manual router with your own hands.

Before you start constructing a milling coordinate table with your own hands, you need to determine the place where it will be located, and also decide what type of milling equipment you want to make. So, you can make an aggregate router with your own hands (the table will be located on the side of the sawing equipment, serving as its extension), a compact desktop machine, or free-standing stationary equipment.

You can opt for compact benchtop equipment for working with wood and other materials if you access it irregularly or often use it outside your workshop. This installation, which is distinguished by its small size, takes up very little space, and if desired, it can be hung on the wall.

If the size of your workshop allows, then it is better to adapt the base of a stationary milling machine for the milling machine, which is much more convenient to work on than on desktop equipment. To make such a device more mobile, it can be placed on wheels, with which you can easily change its location.

A simple milling table or table for a drilling machine can be made very quickly. To make such a structure, which can easily be placed on a regular desktop, you will need a sheet of chipboard on which the guide elements are fixed. As such a guide, which can be used as a parallel stop for a milling table, an ordinary board of small thickness, which is attached to the tabletop using bolted joints, is suitable. If necessary, you can attach a second such board in parallel, which will serve as a limiting stop.

To insert a router into a table, you will need to make a hole in a sheet of chipboard to accommodate it, and it will be fixed to the tabletop using two clamps. After this, the manufacture of the milling table can be considered complete. To make the use of this design more convenient, you can place simple clamps for a milling machine on the tabletop.

Elevator for a router: several DIY options

A lift for a router, which can be purchased in a serial version or made by hand, is a device that allows you to improve both the quality and accuracy of processing performed with hand-held power tools. The results of the latter strongly depend on how accurately and confidently the user manipulates such a device. In order to minimize the influence of the human factor on the results of processing performed with a manual milling cutter, special devices were developed.

Homemade elevator for a manual router, made of plywood and timber

One of them is a mechanized lifting device for milling power tools, which, in full accordance with its functionality, is called an elevator. As mentioned above, such a device can be purchased in a serial version, but it will not be cheap, so many home craftsmen successfully make it with their own hands.

This is interesting: How to make a homemade frame for an angle grinder

How to make it yourself

To make an elevator with your own hands, you need a certain set of tools, as well as instructions and drawings. There are several options for what to assemble such a structure from. The most popular is the jack.

What will it take to do

To manufacture a lifting mechanism on your own, you will need a whole list of tools, technical devices and various materials. You should have:

- directly to the router, the handles are first removed from it;

- electric drill;

- an ordinary car jack;

- textolite or metal sheet;

- wooden bars (square cross-section);

- aluminum profile;

- plywood and chipboard;

- metal guides;

- threaded rod;

- wrenches, pliers and screwdrivers of different sizes;

- drills of different diameters;

- epoxy adhesive;

- square, ruler, tape measure.

You may also need a grinder and a welding machine. It all depends on the specific assembly scheme, since there are several options.

Instructions and drawings

Home craftsmen most often use a standard machine jack to make a lifting mechanism. But there are also designs, the components of which are: a support disk with a threaded rod and a flywheel disk, there are options with a chain drive and microlifts. Each system has separate manufacturing instructions.

From the jack

The operating principle of this mechanism is based on raising and lowering the working head of the milling cutter using the control of a standard jack from the car.

Manufacturing algorithm:

- A box should be made from chipboard or 15 mm plywood, which must be attached to the bottom of the desktop. The box is simultaneously a protective casing for all devices and a supporting device for the structure.

- Inside the box there should be room for a jack and a hand router, which is attached to the moving part of the jack.

- Screw the jack from the bottom of the support casing.

- Attach a hand router to the inner surface of the workbench tabletop.

- The support plate in such a device will be a metal or textolite sheet.

If desired, you can add an electric drive to the design, but this will be more expensive equipment.

With threaded rod

This design requires a threaded rod, a small handwheel and a support disk. Manufacturing instructions:

- you need to get a board, the thickness of which is 1.8 cm and cut out a circle - this is a support for a hand router;

- in the center of the circle, cut a hole with a diameter of 1 cm; a threaded rod with a length of at least 5 cm is placed here;

- connect the stud to the support platform using two nuts and washers;

- connect the lower part of the stud to the flywheel;

- A flange nut is built into the bottom of the hole through which the lower part of the stud will be passed. She will be directly responsible for the functioning of the entire mechanism.

Also in this design you can use a mechanism that will provide the power tool with sideways movement.

With chain drive

This manufacturing option takes longer. The design is a frame where the lower milling plate is connected to the upper one using pins, which are the main working tool along which the movable insert moves.

The movable insert is a two-layer plate, between the layers of which nuts with stars mounted on them are inserted. The drive sprocket is mounted through a bushing onto the shaft

It is important that the drive and driven sprockets have a tooth ratio of 1:2. For the design you can use a standard bicycle chain

It is imperative to ensure chain tension for the structure to function properly. To do this, it is necessary to install a metal crescent into the structure, which will have tension at one of the corners and at the same time rotate freely. An eccentric is mounted nearby, when turned, the crescent will be pressed weaker or stronger, which ensures chain tension.

Microlift

A microlift can be made quite simply using a running nut and a cable. First you need to secure the platform for the lower elevator roller. Then you should adjust the height of the roller and the shape of the platform. Before installation, the stud must be adjusted to size using a lathe. The result will be a pin-shaft.

You need to make a loop on the cable. Then the flywheel is installed, and the loop is secured to the running nut in the guide. As a result, 10 rotations of the flywheel can result in 9.5 mm of cutter movement.

What tools will you need?

To make a milling lifting mechanism with your own hands, you will need the following list of tools and additional materials:

- drawings – own or found templates;

- milling machine, always with the handles removed;

- electric drill;

- sheet of metal or textolite for the base plate;

- blocks of wood with a square cross-section;

- car jack;

- plywood, chipboard;

- aluminum profiles;

- metal guides;

- threaded rod;

- screwdrivers of different sizes and types;

- spanners;

- pliers;

- bolts, screws, nuts of different sizes;

- drills with different diameters;

- epoxy adhesive;

- ruler, tape measure;

- square

Important! The set of tools depends on the type of milling elevator design. You may also need a grinder, a circular saw, a jigsaw, or a welding machine.

Buy or make it yourself?

There is a wide choice of offers on the power tool market. Industrial microlifts look good and work without failures, but their cost is the same as that of a new router. True, the device is quite well equipped. The kit includes rings for the copy sleeves, and a very high quality mounting plate.

Industrial microlift for a router with a set of copy rings

All that remains is to electrify the device - and you can get a CNC machine. There is only one drawback, but it outweighs all the advantages - the price itself. Therefore, for occasional home use this is an unaffordable luxury. So our Kulibins make whatever they can. However, there is a lot to learn from them.

Make a lift for the router yourself, or buy a ready-made one? Let's answer this question

When using a manual router installed in a stationary table, two questions arise:

- How to adjust the depth of immersion (extension) of a cutter.

- How to quickly change replacement tips.

Unscrewing the tool from the plate every time is too troublesome. In addition, a statically mounted router works in the workpiece only at a fixed depth.

This problem is solved by installing a height-adjustable suspension on the router. And once you were able to make a full-fledged milling table, installing an elevator of your own design is not difficult at all. In addition, a self-made device is developed taking into account all the requirements of the master, even those that are not provided for by the factory device.

Why do you need a lift on the milling table, and is it possible to do without it?

This useful device is called the third hand of the master. Those who have tried a milling cutter with a microlift are finding new applications for it:

- Maintaining a power tool is not difficult, as is quickly changing cutters.

- You can change the cutter reach height in a matter of seconds, and most importantly – safely.

- You can change the immersion depth “dynamically”, simultaneously with the movement of the workpiece on the table. This expands creativity.

- Due to the fact that you no longer regularly dismantle the tool for maintenance, the plate and its fasteners are subject to less wear.

Buy or make it yourself?

There is a wide choice of offers on the power tool market. Industrial microlifts look good and work without failures, but their cost is the same as that of a new router. True, the device is quite well equipped. The kit includes rings for the copy sleeves, and a very high quality mounting plate.

Industrial microlift for a router with a set of copy rings

All that remains is to electrify the device - and you can get a CNC machine. There is only one drawback, but it outweighs all the advantages - the price itself. Therefore, for occasional home use this is an unaffordable luxury. So our Kulibins make whatever they can. However, there is a lot to learn from them.

There are quite primitive lever-type designs

Homemade elevator design with a lever mechanism

This technique even allows the use of a “foot” drive.

It is not suitable for precise reach settings, however, with the help of such a mechanism, you can raise the router to the working position with one movement, and just as easily lower it to change the attachment or service.

This elevator has a fairly long stroke; it does not allow for adjustable milling. Materials for manufacturing are literally lying underfoot, the cost tends to zero.

Popular: The best cutters for a hand router - types, types and varieties

Using a Screw Adjuster

Another example of a homemade elevator for a router

The design is more advanced and allows relatively precise adjustment of the reach. However, using such a microlift is inconvenient; to rotate the handle, you need to crawl under the table, and then make a control measurement of the height of the cutter. But the reliability is high, and production does not require expensive materials. Such an elevator can be made “by eye” without using drawings.

The following flywheel design not only makes it possible to precisely adjust the reach in small increments within 50 mm, but is also quite convenient.

Lifting design with flywheel

It will take more time to make, but the result is worth it. The flywheel allows you to adjust the height of the cutter, while simultaneously visually monitoring it above the working surface. In principle, it is already possible to dynamically change the cutter offset.

The main advantage is the still low cost of components for manufacturing, with increased functionality. Instead of a flywheel, you can install a gear and a motor with a gearbox. But this will require additional costs.

Option with car jack

Quite expensive, since at a minimum you need to purchase a jack. Diamond-shaped designs are ideal.

Using a screw jack as a lift for a router is also possible

This microlift lift is reliable, and thanks to the handle located parallel to the tabletop, it is convenient and quite accurate. Positioning the mount is quite simple. It is enough to install a strong shelf parallel to the tabletop. An electric drive option is available.

Then, in general, you can install a foot pedal and free both hands. And if you add a programmer to all this, you have a homemade CNC router. However, this goes beyond the concept of an economy class device.

Option from an advanced master

Since the possibilities of a craftsman are limitless, you can come across completely unexpected designs. This microlift is made using the very same router for which it is intended.

Original elevator design made by hand

The design involves not only precise adjustment of the reach, but also changing the angle of inclination of the router axis. With this potential, you can significantly expand your woodworking tasks. The drive of the worm gear of the stud – the height regulator – was originally designed.

Gears (gears) are made using the dovetail tenon method. This allows the gears to be moved outside the mechanism, eliminating the need for lubrication, and making adjustment smooth. The material used is moisture-resistant plywood 20-25 mm thick. The microlift is made so well that I would like to suggest that the author organize industrial production.

Of course, such a design requires a preliminary drawing.