A huge number of people do the right thing by thinking in advance about the entire process of renovation and any other changes to their apartment or their own home. If you want to change interior doors, you should thoroughly study all the nuances of this seemingly simple job.

It seems that everything is simple, I bought a door and put it in the required place. In fact, not only do you buy a door, you also need to polish it in order to install it correctly in the doorway. Important work includes: marking, inserting door hinges and much more.

In order not to lose a large amount of money due to a damaged product, and to correctly understand the issue, to understand what needs to be done and how, just read this article, in which you will find answers to all questions.

Marking for loop

An important part of the correct installation of any furniture hinges is, of course, the most accurate markings. If it is done poorly, it will certainly affect the functionality of the door.

The correct markings for furniture hinges will help you find the right center to make the recesses.

You need to “move away” 7-12 centimeters from the edge. The number of hinges is standard two, but it can vary depending on the type of furniture. It is necessary to maintain a specific distance between the loops. It is equal to fifty centimeters. The door parameters depend specifically on the number of canopies.

When you have finally decided on the quantity and all the necessary dimensions of furniture hinges have been installed, you can mark the central holes in relation to the width of the door. The distance from the side should be approximately two centimeters. It is also impossible not to take into account that the fastening should not be placed where the shelves in the closet or cabinet should be.

After taking all the necessary measurements, make notes. Remembering to respect the width spacing, mark the placement point. At the intersection of these marks, you need to make a “hole” with a nail or a self-tapping screw. If the facade is higher than a meter, make notes every half meter.

For more precise marking, you can use a special template called.

How to replace furniture hinges on an old cabinet

When replacing furniture hinges, it is advisable to replace the installation screws with thicker ones (for example, take 4x16 or 3.5x16 versus 3x16). This will ensure the strength of the fastening in the same holes.

If you need to replace furniture hinges on an old cabinet because they were torn out from the sides or the facade itself, it is necessary to carry out preliminary restoration work. You can read more about this in the article on how to repair a cabinet with your own hands.

Adjustment

Adjustment (or adjustment) is the final stage of installation of furniture hinges. It must be performed in several planes at once - vertically, horizontally, and in relation to depth:

- Adjusting the depth will help press the door closer to the body, or ease the pressure. You need to tighten the oval hole.

- On the vertical side - it will help to move the facade. This is done by twisting oval-shaped holes.

- On the horizontal side - ensures free movement of the door back and forth and back. The purpose of this adjustment is to avoid gaps between the cabinet and the door. The method is great for rooms with uneven floors or walls.

Now you know how to secure furniture hinges. As you can see, this is not so difficult to do. You don't need to have any special skills or abilities. Doing this kind of work with your own hands will be another reason for a little pride.

What cutters should I use to install hinges?

The hole for the hinges can be made with the same large cutter as for the lock. But, as a rule, groove cutters with a cutting edge at the end and sides of a smaller size than for a lock are used for this.

A special loop cutter looks like this:

It has a shorter shank and a wider cutting part than the locking cutter.

Professionals who have to work with dozens of doors every day use not only a separate cutter for hinges, but also a second lightweight cutter. On it, the required depth is set once according to the thickness of the hinge, and there is no need to change the adjustment for the lock and back for the hinges each time. This speeds up the work.

Other types of loops

So, all types of loops can be classified in different ways. Thus, there are different types according to design, purpose, method of fixation and application. In general, there are several dozen types of furniture hinges, some are more common, some are less common, but almost all find application in various types of furniture designs. In addition to four-hinged hinges, let's look at a few more variations of hinges that may be encountered by furniture assemblers or people who have bought new interior items and decided to assemble them themselves.

Card loop

Card loops are considered the oldest. Their ancestor is a forged hinged hinge with a long overlay. Outwardly, they resemble an ordinary door hinge, only slightly smaller in size. The design consists of two metal strips connected in parallel using a thin rod that acts as a hinge. Nowadays they are rarely used, but are indispensable in the manufacture of retro-style furniture.

Butterfly door hinges

Pendulum type hinges or bar hinges make it possible to open the door 180 degrees. What happens is something similar to how the doors open at the entrance to a saloon in old westerns.

Bar loop

Mezzanine hinge structures are designed to attach horizontally oriented doors that will open upward. The hinges have a spring mechanism and also allow you to fix the door when open. They resemble ordinary overhead variations of loops.

Mezzanine hinge MK01

Ombre structures are used for so-called hinged doors. They will be mounted on both ends of the cabinet and do not require insertion, but may require minor milling (up to 2 mm). Then the sash can be opened 180 degrees. This is an ideal hinge for a folding table.

Hinge for folding elements

Secretory structures are similar to the card ones described above; they have an axial hinge and plates. They make it possible to open the façade downwards and keep it in a horizontal position. They can be accompanied by a special bracket that provides a supporting function. Usually installed in those cabinets where a bar is provided.

Secretory loops

Blind hinges, otherwise called adit hinges, are used for doors on the side of the cabinet that is adjacent to the wall. They can be used to attach the door to the false panel.

Gallery hinges

Heel products are extremely rarely used because they are designed only for lightweight doors. But they can be installed on facades with any type of opening. Installation is carried out in the lower and upper parts of the sash.

Heel loops for furniture

There are special hinges for glass sashes. They also come in different types, but their advantage is that they can withstand significant loads, and they look very beautiful.

Glass hinge

And relatively recently, hinges with 8 hinges, eight-hinged, appeared on sale. To install them, you do not need to resort to milling or cutting. This is an improved variation of the usual four-joint hinge. True, they are more difficult to install, and therefore, despite the absence of the need to carry out any preparation, such loops are rarely used.

8-joint hinge

The nuances of installing furniture hinges on a glass cabinet door

Similar to chipboard furniture hinges with a 26mm bowl, special furniture hinges for glass doors are installed. Using the adjusting screws, you can align the facades in the “left-right” position up to 5mm, “top-bottom” up to 2mm and “closer-further” from the frame up to 2.5mm.

| A plastic bowl with a seal is inserted into the pre-drilled hole, and the hinge arm is snapped into it. |

| The strike plate is installed to the desired depth with an internal glass facade and to a depth of 37mm with an overhead hinge for a cabinet. |

| Next, to install the hinge on the glass cabinet door, you need to thread it through the striker plate and secure it with adjusting screws. |

The canopy adjustment for the glass door is made in the same way as for all four-hinge hinges. After alignment, a special plug (metal or plastic) is placed on the outside of the bowl mechanism.

Since glass with drilling is quite fragile, it is recommended to install additional dampers (closers) to soften the impact of the door on the body. You can implement a push-opening system by installing a magnetic pusher with applied metal handles on the top or bottom edge of the glass door.

Making your own template

Making a template for furniture hinges with your own hands follows a clear plan

It is important to follow the sequence of steps. If you follow all the rules, then there will be no difficulties in the process.

Stages of developing a template for loops:

- Selection and preparation of materials;

- Preparation of necessary tools;

- Development of template details;

- Final assembly of all elements.

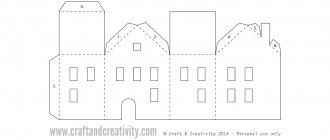

Paper template for download

- To create a template yourself, you need to print a sample.

- According to its dimensions, make a blank from solid material, plastic or wood

- Attach the paper template to the workpiece

This is what should happen

To create a workpiece you will need to take a drill, router, hammer, jigsaw. You will also need tools for drawing markings. First you need to make a base. The optimal dimensions are 19x38 cm. A hole measuring 13.5x7 cm should be made in the center. The edges should be smooth. A router will help with this.

Bolts need to be placed on the workpiece

It is important to maintain symmetry relative to the width of the base. The bolts must be deepened into the structure so that they do not interfere with further manipulations

The hole is made wider than the connecting elements and additionally driven in using a hammer.

It is necessary to retreat 7 mm from the 13.5x7 cm holes and make small notches. Around an element with dimensions of 37.5x7 cm, notches are made on one side at a distance of 30 cm from each other.

A homemade template requires a holder measuring 2x5 cm and a length of 5.8 cm. You will need to install a limiter on one of the sides, which looks like a small block. This element will not allow the distance to shift when installing the facade.

Then all parts of the template are attached. Washers are installed under the bolts and nuts. This element increases the durability of the template. The manufacturing process does not require special skills or knowledge. It is enough to familiarize yourself in detail with the template development scheme.

Selection of materials for work

For the template, you can use plywood, chipboard or MDF. More durable structures are made of plexiglass and metal. You can take several materials for one template. So you can use chipboard for the base, and make the guides from a more durable material. It is easier to work with wood, as it is easier to process than glass and metal.

Required connecting elements:

- Bolts. You will need 6 pieces with a thickness of 6 mm and a length of 30 mm. To fix the connecting element, you need to have a 10 key.

- Nuts. Need 6 pieces. The main requirement for the element is convenient adjustment. Wing nuts are most often used.

- Washers. Their diameter should be 6 mm.

- Self-tapping screws. They are selected depending on the thickness of the remaining connecting parts.

Furniture template for overhead hinges

The hinge template is designed to simplify the process of installing facades; it is often called a hinge jig. To use the sample, you do not need to have any special skills or knowledge. First you need to mark the location for the center of the fastener. Then the template is applied. Its nose should coincide with the applied mark.

Next you need to mark the hole for the strip. This can be done with a marker or a self-tapping screw. Then the template is applied so that its nose coincides with this mark. Next, the place for attaching the bowl is marked. Using a cutter, make a hole for the internal hinges. Self-tapping screws are used to secure the fittings.

Features of working with the template:

- The sample is made of durable materials, but it must be treated with care. For this reason, drilling through a template is prohibited. This may reduce the life of the product.

- When marking, be sure to step back 1.1-1.2 cm from the edge.

- Hinges from different manufacturers may have slight differences in size - the spacing between the centers of the screws. Then the template is used to determine the location for the cup. This hole is universal for all fasteners.

The number of hinges depends on the dimensions of the doors. The cutters are selected depending on the façade material. It is recommended to use reinforced self-tapping screws for fastening. During operation, the risk of damage to the fittings is reduced.

Description

A furniture jig is a special template tool that is often used by specialists in small and large enterprises to mark drilling points on products and, in some cases, also ensures that the drill fits straight into the material. Depending on the needs of the master, conductors can be either factory-made or self-made. Most often they take the form of a metal template with sleeves for the hole and marking the distance between them. The main advantage of using a furniture jig is that specialists spend less time taking measurements and making markings for drilling.

Using it, you can quickly mark the necessary points on the product blanks, and then make their high-quality connection using different fastening methods. The scope of its application is quite wide, but most often it is used for quick insertion of standard furniture hinges. The device may vary in appearance and markings on the template depending on its intended purpose and operating conditions. For example, a jig for furniture hinges in the production of doors will differ significantly in appearance from a jig that is used to fasten massive furniture doors.

How to install a lock on an interior door

Inserting a lock into an interior door always begins with markings. To prevent the cutter from tearing out the edges of the laminate, the slot location is sometimes covered with masking tape and markings are made on it. Or cut with a sharp knife.

The selection for locking is done in 2 levels:

- a small sample for the overlay strip, to the depth of its thickness.

- deep sampling under the body of the castle itself.

First, the height of the lock is determined. Then a lock is applied from the bottom mark upwards, and marks are made along its cover plate.

The markings for the lock itself are applied after a small sample has been made for the overlay strip. The markings for the lock itself are done like this:

- The center of the door leaf is located in thickness. For example, if the thickness is 37 mm, the center is marked 18.5 mm from the edge.

- The thickness of the lock is measured. If it is 18 mm, 9 mm are marked on both sides from the center of the canvas.

- Several such markings are made, then they are connected by a line of a pencil or marker.

The length marking is made according to the actual size of the lock, it is applied and the markings are made according to the fact.

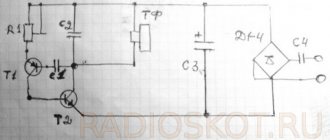

Instrument setup

The setup is carried out two times:

- For shallow cutting under the lock trim plate, the cutter extends beyond the support platform to the thickness of this strip. For example, 2 mm. A parallel stop is set so that the cutter cannot go beyond the edge of the marking on one side, but follows exactly along the marking. The second marking line when cutting without a template is controlled manually, visually.

- After shallow sampling, the cutter is released to the required depth under the deep sampling, under the lock itself.

An approximate progress of work on such an insert can be seen in the following video.

It is approximate because the marking sequence is different here - all the markings for the overlay plate and the lock body are applied at once. But after selecting a niche for the bar, the markings for the lock itself are removed. Therefore, it is better to adhere to the markup order described above:

- Marking for the bar.

- Sample.

- Marking for the lock itself.

Selecting a lock using not just one parallel stop, but a double-sided adjustable template is shown and understood from the following video:

Drilling holes

Installation is carried out with all the rules:

The depth of the hole for the furniture hinge should be about thirteen millimeters. If possible, the insertion of furniture hinges should not be deeper, otherwise the front side of the canvas may crack; The diameter of the hole depends strictly on the cup of the loop

Tools must be completely aligned with their axis to prevent damage to the surface; A sharpened cutter will help protect the blade from damage and chips; Do not rush while drilling, otherwise there is a risk of doing it sloppily; It is worth paying attention to the dimensions of the cups and their dimensions when installing furniture hinges;

Having drilled one hole, proceed to the next and so on until all the holes for laying the hinges are prepared.

What tools should I use for this?

The bowl must be secured to the facade, and the bar to the body of the bedside table. The furniture hinge must be inserted into the hole, which must be made in advance. The shoulder of the loop becomes a kind of bridge, now connecting both parts. To make holes for such loops, you need to prepare the following tools:

- screwdriver or drill;

- special drill-mill;

The diameter of the cutter for the hole for a furniture hinge is 35 millimeters or 25-26mm. It is selected depending on the size of the loop cups. To create holes for such hinges, you can also use a simple drill.

A multifunctional drill, with attachments that are easy to replace, is quite suitable for such work.

The middle spike must be installed in the center of the circle, outlined using a specially prepared caliber. Automatic calibration is used on the corresponding machines, but at home the master cannot do without a specialized electric tool.

During installation, hinges require a high level of care and precision. The chance to complete exactly the required niche is the most important advantage of the so-called Forstner drill. It can provide a stop that will prevent you from penetrating further than required. And the teeth of the drill do not allow it to deviate from the intended “course”. The end result is an almost perfect hole. And due to this, the cup fits into the recess quite tightly.

But the above-mentioned drill also has one significant drawback, which manifests itself when working with a solid piece of wood. This is low quality, which is to be expected if the instrument was not made in a factory. This is why you should choose tools exclusively from official companies. And, of course, don’t forget about warranty cards.

Depending on the type of panel you are working with, the cutter can get quite hot. Due to this, it can burn the edges and wood that is removed from the recess. That is why, when working with such a foundation, you should not forget about breaks in work. So that the drills have time to cool down at least a little. Working in three to four sets will be ideal.

Particular attention should be paid to breaks when working with MDF sheets. If the activity is carried out with chipboard sheets, parts made of strong alloys will be able to make recesses for hinges really quickly and without much stress

Universal furniture jig for drilling

In terms of functionality, it combines the two previous devices, since it can adapt to marking with drills of different diameters, and the ruler allows you to set any desired distance from the edge and pitch. It is used both for drilling the front surface of parts and the end.

Well-known manufacturers of furniture jigs include Cheron, Kreg and Wolfcraft. Before choosing any model, we recommend comparing prices, quality and functionality with smaller manufacturers and suppliers of furniture components Blum, Hettich and others. Often the optimal price-quality ratio, and even with a guarantee, can be found where it seems that “everything is expensive.” Do not exclude this possibility for yourself and consider all possible options. After all, a furniture jig can serve faithfully for many years, helping to speed up production processes without losing the quality and accuracy of making furniture with your own hands.

Fastening rules

Most often, no preparation is needed to connect parts made of wood using self-tapping screws - the screws can be screwed into the part without drilling a hole. For these purposes, use a Phillips screwdriver or screwdriver. You need to act smoothly and carefully, especially when working with oxidized screws (they are considered the most brittle).

The tool should be kept strictly in line with the screwing hardware. You should not try to screw the fastener into the knot - despite the fact that these are the densest areas, such fastening will be considered ineffective. If you plan to screw screws into high-density natural wood, it is recommended to pre-lubricate the hardware with laundry soap. It will act as a lubricant and ensure easier insertion of the fastener into the material.

It is worth considering that the screw should not go through the 2 structures being connected.

Before drilling, you need to apply markings, and then make a hole in the main part measuring 0.8 times the diameter of the screw. The depth of the hole must correspond to the screw-in base of the hardware. If the fasteners are thin, you can use an awl.

When drilling soft lumber, it is also possible to make holes by hand. To work with hard materials, drill a hole that matches the profile of the screw-in fastener. To make a recess you need a drill and a drill. It is best to use a countersink.

After the preparatory work, the screw is inserted into the hole. It must be strengthened in the material by twisting it clockwise with a screwdriver. In this case, the correct selection of hand tools is important. If you take a screwdriver that does not match the size, there is a high risk of damaging the slot on the head - in this case, it will be impossible to tighten the fastener. You can also fasten screws using electric or pneumatic screwdrivers. Their use makes work easier and speeds up the assembly process.

The final stage is installing stickers or plugs on the fastener heads. Such accessories are sold in a wide range of colors. Their main task is to camouflage fasteners. Thanks to the use of stickers, you can increase the aesthetics of finished furniture.

For more information on screws and self-tapping screws, see below.

Manual installation

This operation is carried out using tools such as a pencil, tape measure, electric drill, wood drill with a diameter of 10-14 mm, a chisel of 14 and 20 mm, and round files.

At a level of approximately 0.8-1 m from the floor, the position of the locking fittings is outlined. In order to mark the width, height and recesses as accurately as possible, the lock is applied to the surface of the door sideways. Do not forget about the marks on the end of the door, since it is from this part of the door that the installation of the lock begins.

First, a small recess is drilled into the end of the blade. Then, using a chisel, the groove is widened and leveled so that irregularities do not interfere with the free insertion of the lock into the recess.

After the groove is ready, through recesses are drilled alternately on each side of the door at the marks for the location of the handles and the cylinder. The edges must be smoothed with a round file.

You can start assembling the castle. The lock itself is inserted into the groove at the end of the door, fixed with a rod, onto which the halves of the handle are then threaded. Next, the core is installed (in the case of a collapsible lock) and the operation of the lock is checked in the open position of the door.

If the mechanism is working properly, we pull out the tongue, close the door and mark on the frame the location of the future groove for the tongue. Using the outline, a groove is cut out using a hammer and chisel, which is subsequently decorated with a decorative overlay. It is recommended to slightly recess this plate into the surface of the frame, also using a recess made with a chisel.

The finishing touch is the installation of a decorative plate on the lock at the end of the door and handle linings.

The procedure for manufacturing a device for inserting loops.

✔ Cutting the blanks. ✔ We make a base from the board. ✔ Cut the thrust strip with dimensions 50×20×580 mm. ✔ Cut a rectangular hole with a jigsaw.

✔ We refine it with a cylindrical cutter so that everything is as smooth as possible. ✔ We drill six through holes ø6.2 mm in the board to insert six hexagon head bolts.

Advice. In order to prevent the bolts from turning while screwing the wings, it is necessary to recess the heads of the bolts into the body of the base board of our device.

✔ To do this, we do not drill holes ø9 mm through to a depth of 5 mm. ✔ Using a hammer, press the bolt flush with the plane of the board. ✔ We use a jigsaw to cut out the linings for the stops from MDF with a thickness of 10 mm. ✔ We mark and mill the slots with a ø8 mm cutter.

✔ We assemble the entire structure.