This article is intended for those amateur astronomers who have already played with binoculars and a refracting telescope, looked at the phases of Venus, the rings of Saturn and the moons of Jupiter, and want something less boring and more stunning. For example, 1000x with a huge lens. It is impossible to do this with lenses alone: they produce so-called chromatic aberration, which manifests itself in the form of rainbow halos around objects, the stronger the stronger the magnification of the telescope.

Therefore, the task arises of assembling a homemade reflecting telescope, that is, a telescope on mirrors. In its simplest form, it consists of two mirrors (objective and diagonal) and one eyepiece lens.

How to make a parabolic mirror with your own hands

Date of publication: September 13, 2019

A small mirror from a lady's cosmetic bag, reflecting the flow of sunlight, can easily light a bunch of dry grass on a clear day. This simple fun is known to many generations of citizens who spent the summer holidays outside from morning until late evening. What happens if you increase the area of the mirror? It is easy to guess that in this case the amount of captured and reflected solar energy will increase sharply. And it would be a shame not to find a worthy use for it, especially since heat prices today are growing exponentially.

Inquisitive minds who know physics quickly figured out how to construct a solar oven. Its first models easily heated food and boiled water, but could not cope with more complex tasks. The solution was to assemble a so-called parabolic reflector with a mirror inner surface. Sunlight, reflected from a curved surface and concentrated at one point, provided up to 1 kW of energy, completely free. All that was left to do was to place a cooking container at the point where the rays coincided and make sure that the surface of the parabola always looked directly at the sun. Minimum costs and high efficiency are not bad when it comes to country or camp life.

Having quickly assessed the capabilities and prospects of parabolic mirror systems, scientists were able to use them in large-scale technological processes. Today, models with a diameter of about 50 m are successfully used for processing refractory materials, the cost of processing which in an industrial environment would completely absorb the expected profit for many years to come. Huge mirror structures installed in the highlands of Europe and America provide up to 1200 W of free thermal energy, and the temperature at the point of convergence of the rays reaches 3000 ° C, simultaneously melting several hundred kilograms of metal compounds. Fast, cost-effective and free - this is exactly how a parabolic mirror works, converting the deadly energy of a hot star into useful and free heat.

Advantages and disadvantages

Self-assembled solar ovens vary in size, but are identical in structure, and therefore there are no difficulties with assembly. Ovens can easily store heat to heat food. The principle of operation is based on absorbing the energy of the sun's rays and redirecting them to the desired object.

Solar ovens have the following advantages:

- Cheapness. To operate, you do not need to buy fuel or use additional energy sources. To work, you only need sunlight.

- Food is prepared as safely as possible - there is no fear of fire, as when starting a fire.

- The stove is easy to care for and simple to use - you just need to direct the sun's ray to the desired object through the mirror surface.

- Mobility. The stove is quickly assembled and disassembled. Therefore, there are no problems with transportation.

- Environmentally friendly.

- Food heats evenly and there is no risk of burning. There is no need to stir the food.

These qualities have made solar ovens very popular among travelers. The stove is easy to cook food on. To cook food, you just need to direct the sun's ray to the desired object.

DIY parabolic mirror: a little theoretical preparation

Externally, a parabolic mirror resembles a satellite dish, the inner surface of which is made of fragments of mirrors. The sunlight falling on it is completely reflected. In this case, the angle of incidence is equal to the angle of reflection, so the reflected light flux is concentrated at one point at a short distance from the structure. Simple calculations regarding the diameter and angle of inclination of the mirror walls make it possible to increase the temperature at the point where the rays converge to 2000° C. This is quite enough to prepare a tasty and aromatic meat dish for several people in a small metal pan.

The fly in the ointment of a huge ointment from a solar oven is the problem of assembling a mirror surface. Individual fragments are unacceptable here: it will not be easy to place them at the same angle on the convex container of the structure. And numerous seams and joints weaken the reflected solar flux, which reduces the amount of thermal energy received. When constructing prefabricated parabolic mirrors of significant size, this problem does not arise, because It is easier to work on a large surface. But when trying to create a small model, you have to either assemble a plate from individual mirror fragments, or use vacuum technology for gluing a reflective film.

Operating principle of solar heaters

Before you start making a homemade solar system, it is worth studying the structure of factory-made solar collectors - air and water. The former are used for direct heating of premises, the latter are used as water heaters or non-freezing coolant - antifreeze.

Reference. Air installations are not very popular due to limited functionality. Solar water heating collectors are more in demand because they can provide heating, hot water supply, and raise the temperature in outdoor pools.

The main element of the solar system is the solar collector itself, offered in 3 versions:

- Flat water heater. It is a sealed box, insulated from below. Inside there is a heat receiver (absorber) made of a metal sheet on which a copper coil is fixed. The element is covered with durable glass on top.

- The design of the air heating manifold is similar to the previous version, only air pumped by a fan circulates through the tubes instead of the coolant.

- The design of a tubular vacuum manifold is radically different from flat models. The device consists of durable glass flasks in which copper tubes are placed. Their ends are connected to 2 lines - supply and return, the air from the flasks is pumped out.

Addition. There is another type of vacuum water heaters, where glass flasks are tightly sealed and filled with a special substance that evaporates at a low temperature. When gas evaporates, it absorbs a large amount of heat, which is transferred to the water. During the heat exchange process, the substance condenses again and flows to the bottom of the flask, as shown in the picture.

Construction of a direct-heated vacuum tube (left) and a flask operating by evaporation/condensation of liquid

The listed types of collectors use the principle of direct transfer of heat from solar radiation (otherwise known as insolation) to flowing liquid or air. A flat water heater works like this:

- Water or antifreeze moves through a copper heat exchanger at a speed of 0.3-0.8 m/s, pumped by a circulation pump (although there are also gravity-flow models for outdoor showers).

- The sun's rays heat the absorbent sheet and the coil pipe tightly connected to it. The temperature of the flowing coolant rises by 15-80 degrees depending on the season, time of day and street weather.

- To eliminate heat losses, the bottom and side surfaces of the housing are insulated with polyurethane foam or extruded polystyrene foam.

- The transparent top glass performs 3 functions: it protects the selective coating of the absorber, does not allow wind to blow across the coil, and creates an airtight layer that retains heat.

- The hot coolant enters the heat exchanger of the storage tank - a buffer tank or an indirect heating boiler.

Since the water temperature in the apparatus circuit fluctuates with the changing seasons and days, the solar collector cannot be used directly for heating and domestic hot water. The energy received from the sun is transferred to the main coolant through the coil of the tank - battery (boiler).

An exception is solar installations for swimming pools, which heat the reservoir water directly or through a simple heat exchanger.

The efficiency of tubular devices is increased by vacuum and an internal reflective wall in each flask. The sun's rays pass freely through the airless layer and heat the copper tube with antifreeze, but the heat cannot overcome the vacuum and go outside, so losses are minimal. The other part of the radiation enters the reflector and is focused on the water line. According to manufacturers, the efficiency of the installation reaches 80%.

When the water in the tank is heated to the desired temperature, the solar heat exchangers switch to the pool using a three-way valve

Sequence of making a parabolic mirror with your own hands

Before constructing an industrial-sized model, it is better to practice by making a small-diameter parabolic mirror with your own hands. At a minimum cost, you will receive the benefit of a functioning design and working out possible errors.

The design of the compact parabolic mirror is ready. All that remains is to carefully remove the pump and seal the hole under the spool. You can test the product on the next sunny day by placing a small metal container with cold water at the calculated point of sunlight concentration. Make sure that the parabolic mirror is directed towards the light - this will speed up the boiling process. And do not forget about safety precautions by promptly removing fusible objects and flammable liquids from the useful structure.

You need to be logged in to leave a comment.

Source

How to Build a Highly Efficient Solar Water Heater from a Dish Antenna

You can make it yourself based on the front hub of a VAZ car.

For those interested, the photo was taken from here: Rotating mechanismStep 3 Creating a heat exchanger-collector To make a heat exchanger, you will need a copper tube, rolled into a ring and placed at the focus of our concentrator. But first we need to know the size of the dish's focal point. To do this, you need to remove the LNB converter from the plate, leaving the converter mounting posts. Now you need to turn the plate in the sun, having first secured a piece of board at the place where the converter is attached. Hold the board in this position for a while until smoke appears. This will take approximately 10-15 seconds. After this, turn the antenna away from the sun and remove the board from the mount. All manipulations with the antenna, its reversals, are carried out so that you do not accidentally put your hand into the focus of the mirror - this is dangerous, you can get seriously burned. Let it cool down. Measure the size of the burned piece of wood - this will be the size of your heat exchanger. The size of the focal point will determine how much copper tubing you will need. The author needed 6 meters of pipe with a spot size of 13 cm. I think that it is possible that instead of a rolled up pipe, you can install a radiator from a car heater; there are quite small radiators. The radiator should be blackened for better heat absorption. If you decide to use a tube, you must try to bend it without kinks or kinks. Usually, for this purpose, the tube is filled with sand, closed on both sides and bent on some mandrel of a suitable diameter. The author poured water into the tube and placed it in the freezer, with the open ends facing up, so that the water did not leak out. The ice in the tube will create pressure from the inside, which will avoid kinks. This will allow the pipe to be bent with a smaller bend radius. It must be rolled into a cone; each turn should be slightly larger in diameter than the previous one. You can solder the collector turns together for a more rigid structure. And don't forget to drain the water after you're done with the collector, so you don't get scalded by steam or hot water after you put it in place. Step 4: Put it all together and try it out. Now you have a mirror parabola, sun tracking module, placed in a waterproof container, or plastic container, complete collector. All that remains to be done is to install the collector in place and test it in operation. You can go further and improve the design by making something like a pan with insulation and putting it on the back of the manifold. The tracking mechanism must track movement from east to west, i.e. turn towards the sun during the day. And the seasonal positions of the luminary (up/down) can be adjusted manually once a week. You can, of course, add a tracking mechanism vertically - then you will get almost automatic operation of the installation. If you plan to use the water to heat a pool or as hot water in the water supply, you will need a pump that will pump water through the collector. If you heat a container of water, you must take measures to avoid the water boiling and the tank exploding. This can be done using an electronic thermostat, which, if the set temperature is reached, will move the mirror away from the sun using a tracking mechanism. I would add that when using a collector in winter, measures must be taken to ensure that the water does not freeze at night and in inclement weather. To do this, it is better to make a closed cycle - on one side there is a collector, and on the other there is a heat exchanger. Fill the system with oil - it can be heated to a higher temperature, up to 300 degrees, and it will not freeze in the cold.

Where to get it

The main mirror-lens of a reflecting telescope is its most important and critical part. And it is also the most difficult to manufacture. Finding a ready-made mirror of this type is almost impossible.

Although there is one way: you can make this from a concave or convex-concave lens. Find the largest concave or convex-concave lens you can find. It is important that the focal length be as high as possible, and, therefore, the concavity as small as possible: from too powerful concave lenses, not a spherical, but a parabolic shape is required, and this is a completely different deficiency that cannot be improvised in any way.

The most reliable calculation is to find a plano-concave one with a diameter of 10-12 cm and an optical power of 1 diopter. Look for it in optical stores. Thus, a homemade telescope of 1000x will not work, but you can do something with it.

H About making a telescope at home in drafts

I have a simple Celestron PowerSeeker 127 EQ telescope, the one pictured above. My wife gave it to me for my birthday. It was a rather spontaneous gift like this: “I don’t know what to give you, oh look at the store, let’s go in and have a look.” In principle, I was very glad to receive such a gift; it was a very interesting thing. However, while using it, I realized that I wanted more. This PowerSeeker 127EQ telescope has a number of significant design flaws that, due to my inexperience, I simply did not realize. The main disadvantage is the spherical main mirror and the corrective lens for it. As a result, the optical design is overcomplicated and the corrective lens fits inaccurately, which is also not of high quality. In general, I think the quality of the observed image with such a mirror diameter could have been better.

Silver plating using chemistry

Then you need to do silvering to get a mirror. Prepare a solution called Tollens' reagent. In order to prepare this reagent, you need: silver nitrate (lapis), caustic soda (caustic soda) and ammonia solution.

This reagent kit also includes formaldehyde (formaldehyde solution). Dissolve 1 g of silver nitrate in 10 ml of water, and 1 g of sodium hydroxide in another 10 ml of water. Mix these solutions, a white precipitate should form. Add ammonia solution until the precipitate dissolves. This solution is Tollens' reagent.

To use it for silvering, you should pour it into the concave part, which has previously been thoroughly cleaned of any contaminants. If the concavity is very weak, you should make a barrier of wax or plasticine along its edge.

Having poured the reagent, you should begin to add formaldehyde to it in frequent drops. Soon a film of silver will form and it will turn into a concave mirror. Keep in mind that Tollens' reagent does not have a long shelf life; it must be used immediately after it is prepared.

There are also ways to make a concave surface yourself, first of all - grinding the concave surface on glass circles. However, these methods are too complicated and are not recommended for use by beginners.

A diagonal mirror should be made in the same way as a concave one. It should be perfectly straight; For its manufacture, the flat side of any plano-convex or plano-concave is suitable.

Assembly and connection diagram

A do-it-yourself solar power plant is assembled like this:

- Find the output terminals of the charge controller and connect the battery to it. After this, connect the conductors that extend from each panel to the input terminal of the device to control the charge. If the panels come with a cable, this step is not necessary.

- The conductors must be connected according to the scheme “+” to “+”, as well as “-” to “-”. After this, power from the battery is supplied to the terminals located at the inverter input.

- By turning on the charge controller and inverter, you will see that the electricity that the panel begins to produce will charge the battery.

Connection diagram for solar panels and household load

Telescope assembly

The pipe should be open at one end and closed at the other, and painted inside with the blackest paint you can find. The diameter of the pipe should be 1.25 times the diameter of the refractor mirror; if you used a lens with a diameter of 100 mm to make it, take a pipe with a diameter of 125 mm.

Attach the lens mirror to the bottom of the pipe, exactly in the center. To make it convenient to do this, it is better to provide a removable bottom. You can attach the lens to the bottom, for example, with superglue.

Make a hole closer to the open end of the pipe. To calculate the desired position for the hole, measure its radius from the open end of the pipe. This is where the center of the hole should be. The eyepiece will be fixed in this hole (perpendicular to the pipe).

It should hang on the optical axis at an angle of 45 degrees. If the angle is maintained correctly, then when you look through the eyepiece you will see the image. If you don't succeed the first time, experiment with the angle.

A telescope is a precision optical instrument, so care must be taken during manufacturing. Before this, it is necessary to make calculations of the structure and installation locations of the elements. There are online calculators for calculating telescopes on the Internet, and it would be a shame not to use them, but it doesn’t hurt to know the basics of optics either. I liked the calculator.

When choosing the size of the mirror (diameter 114mm), it seems to me that I chose the golden mean: on the one hand, this size of the chassis is no longer quite small, on the other hand, the cost is not so huge that in case of a fatal failure I would suffer financially. Moreover, the main task was to touch, understand and learn from mistakes. Although, as they say on all forums, the best telescope is the one in which you observe.

And so, for my first, I hope not the last, telescope, I chose a spherical main mirror with a diameter of 114 mm and an aluminum coating, a focus of 900 mm and a diagonal mirror shaped like an oval with a small diagonal of one inch. With these mirror sizes and focal lengths, the differences between the shapes of a sphere and a parabola are negligible, so an inexpensive spherical mirror can be used.

Knowing the parameters of the mirror, you can calculate the telescope using the above-mentioned calculator. Not everything is clear right away, but as creation progresses, everything falls into place; the main thing, as always, is not to get hung up on theory, but to combine it with practice.

Below the spoiler are some photos of this process.

Diagonal Mirror Assembly

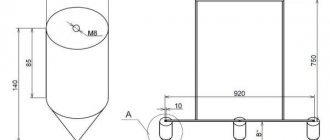

The main mirror mount was made from two 12mm thick plywood discs. One with a pipe diameter of 152mm, the second with a main mirror diameter of 114mm. The mirror rests on three circles of leather glued to the disk. The main thing is that the mirror is not tightly clamped; I screwed the corners and wrapped them with electrical tape. The mirror itself is held in place by straps. The two discs are able to move relative to each other to adjust the main mirror using three M6 adjusting bolts with springs and three locking bolts, also M6. According to the rules, the disks must have holes to cool the mirror. But since my telescope will not be stored at home (it will be in the garage), temperature equalization is not relevant. In this case, the second disk also plays the role of a dust-proof back cover.Homemade solar concentrator oven

First, you should identify the place of concentration; to do this, put on sunglasses. Take a wooden board and thick mittens. Point the reflector towards the sun and focus the caught rays on the board, then adjust the distance until you get the most effective, concentrated beam of energy, do this until you get its smallest size. The mittens you wear will protect the skin of your hands from sunburn if you accidentally place your hands in the focal area of the rays. Once you determine the point of concentration, all you have to do is fix the structure and finish installing it in the optimal location. As they say in inventor circles: “All that remains is to get a patent.” Use the results of your labor by receiving an inexhaustible and free source of energy.

The Stirling engine can be assembled using available, common materials

There are many options for making solar concentrators. In the same way, you can assemble a Stirling engine yourself, using available, common materials (this is really possible, although, at first glance, it seems unattainable), and you can use the capabilities of this engine for a variety of purposes for a long time. All restrictions depend only on your patience and imagination.

The inspiration for the construction of this unit was the program "MythBusters" on the Discovery Channel. In this program, the “destroyers” tested the myth of how Archimedes burned the Roman fleet with the help of mirrors. Twice this myth was destroyed. But nevertheless, it is possible to build a simple focusing mirror that can set fire to a board or cook dinner.

This will require very little.

1. Self-adhesive mirror film (can be bought in wallpaper stores). Window film will not work.

2. A sheet of chipboard and the same hardboard.

3. Thin hose and sealant.

A ring is cut out of chipboard. Later I needed two rings. Otherwise the beam will focus too far. The ring is cut out with a jigsaw.

A circle of hardboard is cut to fit the size of the ring.

The ring is glued to the hardboard

It is important to coat everything well with sealant. The structure must be sealed and not allow air to pass through

We make a hole in the side and insert the hose.

And finally we stretch the mirror film on top.

Then the air is pumped out from the housing and a spherical mirror is obtained. The hose is bent and clamped with a clothespin.

It is advisable to make a stand for this unit.

This thing is scalding, bless you.

It turned out to achieve good focusing. The only bad thing is that this mirror cannot be directed to an arbitrary point. Only in the sun.

Parabolic mirror for a reflecting telescope using a homemade CNC machine

Have you seen how much a reflector with a mirror with a diameter of 18 inches (almost 46 cm) now costs? Therefore, my park of crazy engineering ideas is replenished with a new item!

The idea is to use a cutter mounted on a rotating rod to create concentric grooves of decreasing radius and increasing depth with each new circle. Thus, we obtain a stepped surface close to a paraboloid of revolution, because all changes in the position of the cutter and the depth of its immersion will be calculated using a parabolic function. Next, the surface is coated with epoxy resin and, with the help of rapid rotation of the workpiece, it is evenly distributed over the surface, filling the “steps” and bringing the surface as close as possible to a paraboloid.

The main problems that I will definitely encounter are:

I have always wanted to have a telescope to observe the starry sky. Below is a translated article by an author from Brazil who was able to make a mirror telescope with his own hands and from available materials. Saving a lot of money at the same time.

Everyone loves to look at the stars and look at the moon in the clear night. But sometimes we want to see far. We want to see him nearby. Then humanity created a telescope!

Today we have many types of telescopes, including the classical refractor and the Newtonian reflector. Here in Brazil, where I live, the telescope is a luxury. It costs between R$1,500.00 (about US$170.00) and R$7,500.00 (US$2,500.00). It is easy to find a refractor for R$500.00, but this is close to 5/8 of the salary, considering that we have many poor families and young people expecting a better life condition. I'm one of them. Then I found a way to look at the sky! Why don't we make our own telescope?

Another problem here in Brazil is that we have very little content about telescopes.

Mirrors and lenses are not particularly expensive. So, we do not have conditions for purchasing later. An easy way to do this is by using things that are no longer useful!

But where to find these things? Easily! The reflector telescope is made from:

— Primary mirror (concave)

— Secondary mirror (plan)

— Optical lens (the most difficult part!)

Where can I find these things? — Concave mirrors are used in beauty salons (makeup, shops, hairdresser, etc.);

— Flat mirrors are found in many things. You just need to find a small mirror (about 4 cm2);

— The optical lens is hardier to find. You can get it from a broken toy or make it yourself. (I used an old 10x lens from a broken pair of binoculars).

- You can use water pipes (something between 80mm and 150mm in diameter), but I use empty ink tin and towel tin.

- Some black splashes.

You need PVC pipes, connectors and some cardboard rolls too.

You can use hot glue or silicone paste.

So, no more waiting! Let's get it started!

Solar concentrators. Types and features. Application

The total amount of energy from the sun that reaches the surface of the Earth in just a week exceeds the energy stored in oil, uranium, coal and gas throughout the world. You can save solar heat in various ways. One such solution is solar concentrators. This is a special device for collecting solar energy, which performs the function of heating the coolant material. Typically used for space heating and hot water supply needs. It is precisely this property that distinguishes it from solar panels, which directly produce electricity.