Width of transported material

: up to 70 cm

Length of transported material

: up to 20 meters

Load capacity

: 500 kg

The skidding cart allows you to transport logs not only transported to the road, but also from hard-to-reach places. It is an ideal solution for transporting small volumes of logs within a small area. Additionally, the product is used as a trolley for transporting rolled metal products on metal bases. The trolley does an excellent job of transporting long rolled metal (metal) over short distances. Detailed photographs of the product in the Gallery section

Homemade trailer for » Used engines from Korea. Contract spare parts for Korean foreign cars.

Trolley for transporting logs Sawpilov Expert full version – AgaClip – Make Your Video Clips

Trolley for transporting logs - 15,000 UAH, buy with delivery in Lviv, Kyiv and Ukraine price in the online store

Trolley for transporting beams

Trailer for the Ultratec ATV Expert LOGGING TRAILER

Universal trolley (for transporting logs) – Garden equipment 10672

Lessnab – Lifting, loading, skidding, felling tongs for logs

wheelbarrow for transporting logs - Google Search Transporting logs Pinterest Google and Search

Mini tractor trailer

Do-it-yourself log sawing machine

Roman Zanfirov on Coub – Finebox

How to cut a log into boards with your own hands.

Production of rounded logs: technology

Universal trolley (for transporting logs) – Garden equipment 10672

Trailer for the Ultratec ATV Expert LOGGING TRAILER

Universal trolley – Garden equipment 10499

How to do something yourself, with your own hands - home craftsman website

AN EXCELLENT TOOL FOR CRAFTERS AND HANDCRAFTS AND EVERYTHING FOR THE GARDEN, HOME AND Cottage LITERALLY FOR FREE - SEE FOR YOURSELF. THERE ARE REVIEWS.

If you look at a dacha village, there is a large or small construction site on almost every plot. Various building materials are used, and moving them is often difficult. Meet: a device for transporting timber and logs.

My wife and I moved to the village from Novosibirsk five years ago when we retired. We bought a house with a plot of 20 acres.

Last year the idea arose to build a bathhouse with my own hands.

At first, we were overcome by doubts whether the two of us could pull it off financially and physically. I am 65 years old, and my wife is 60, and we live on one pension.

TOOLS FOR HOME AND GARDEN, HANDCRAFTS, ETC. PRICES VERY LOW

But it turned out that we could do it. You just have to put your hands and think carefully with your head.

In the spring we purchased timber, and the question immediately arose: how to deliver it to the construction site - this is about 100 m.

We are not able to carry it in our arms, we are not the same age. And I came up with a design for transporting timber and logs, which may be useful to other readers.

We bought three wheels with a diameter of 20 cm in the store, one of them is swivel and is placed in the front part of the structure. You will also need a small piece of chain and a thick rope. All this was also bought at a hardware store.

I put together this structure from scraps of timber and planks (see drawing). All sizes are in centimeters.

Everything is very simple, but it makes life a lot easier when building at the dacha, especially for us, pensioners who find it difficult to work with their own hands at full capacity.

Transporting logs on a trolley

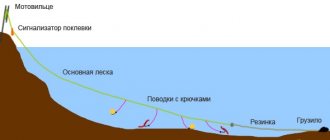

When there is a need to deliver a log weighing up to 100 kg and 4-5 m long, covering a significant distance, say a kilometer or more, it is convenient to use a cart with two large diameter wheels and a body centered along their axis. When loading a log, the cart seems to pile it on itself. To do this, the front edge of the body is brought under the end of the lying log. By lowering the trolley handles down, the end is raised. After this, the handles of the trolley are once again given a sharp push downwards with the expectation that the end will jump slightly. At this moment the cart is pushed forward under the log. As a result of such actions, the log climbs onto the body. Here it is positioned in equilibrium relative to the wheel axle. In this case, the axle completely bears the weight of the load. The carrier's task is only to provide the required traction. If you drive along the road, these efforts will be very insignificant. Interestingly, the cart moves easier when it is pushed from behind, and the log is located at a slight angle towards the road. Then, with its seemingly falling weight, it helps the movement.

The main thing when transporting a log in question is to secure it well on the body so that it does not fidget. To prevent longitudinal displacement, it is enough to drive a nail into the log at a shallow depth from below at the front and rear contours of the body. Lateral movement is prevented by short twines that secure the log to the four corners. With this packaging, it can be transported even off-road, including through the forest. Small rubble and other obstacles blocking the path can be moved over by placing them under the wheels and on the obstacle to descend on a short board. They will serve as a bridge.

Do-it-yourself trailer for a walk-behind tractor: models, designs, creation technology

The issue of modernization and improvement of labor tools has always been a headache for managers of agricultural enterprises. And these days this problem is quite acute. An increase in the number of small farms and subsidiary plots clearly leads to a decrease in their size. And this, in turn, creates specific requirements for agricultural machinery. Where powerful tractors and combines cannot turn around, miniature walk-behind tractors with a wide range of trailed and mounted equipment will pass. In our review, we will analyze in detail whether it is possible to make a trailer for a walk-behind tractor with your own hands, what is needed for this and how technically labor-intensive this process is.

Features of modern industrial models

The main feature of machine models produced by well-known manufacturers today is the use of a laser pointer to control the movement of the carriage. This point determines high processing accuracy and the ability to carry out the entire process without reinstalling the workpiece. Thus, a CNC-controlled carriage with a set of tools moves along guides and performs various types of operations.

Log rounding machine

As practice shows, you can make a model with your own hands that will have manual control and the ability to process workpieces up to 7 meters long.

The device of a trolley for a walk-behind tractor

Before building a cart for a walk-behind tractor, you need to find out what the walk-behind tractor itself is. This is a transport device capable of moving along the surface due to its own internal combustion engine, which is started by pulling out the cord. The power of the power unit of the walk-behind tractor ranges from 3.5 hp. up to 12.0 hp The chassis can be single-axle (most often) or two-axle.

Between the engine and the chassis there is a transmission mechanism that allows you to change gears and change the direction of movement. The control system allows the operator to control the driving modes.

The walk-behind tractor can work in combination with various agricultural and municipal equipment: for cultivating soil, mowing grass, removing snow, and short-term transportation of small loads. In the latter case, a trolley is attached to the walk-behind tractor. Since the drive wheels of the device are lightly loaded, it will not pull a large load on difficult roads. The walk-behind tractor is convenient for cultivating row spacing and working in greenhouses.

Rolling logs

Because the log is a very wide wheel, it can be rolled. The best way to do this is to place a couple of poles under it. There are several ways to move. They roll the log, pushing it with their hands, like a barrel. This is how it is moved over short distances. For longer distances, it is a good idea to use a wooden pole, a light pipe or a crowbar. Acting as a lever, the log is given a rotational movement. It is especially convenient to roll short logs in this way.

If the round timber needs to be delivered over a distance of 20-30 m or more, then it is better to use a rope to move it. One end of it is fixed on the line of movement, and the other is brought under the log from below. It is enough to pull it in the direction of rolling to impart a rotational movement to the log. In this way, logs can be moved over considerable distances, especially along a road or level surface. Poles laid in the direction of travel greatly facilitate and speed up the work.

Possible trailer options for a walk-behind tractor with photo examples

There are as many homemade trailer designs as there are homemade mechanics. Everything is determined by the purpose, available materials and finished parts from old cars.

The presence of a trailer frees the driver from worries about maintaining balance, but somewhat worsens the maneuverability of the vehicle. But the trailer is convenient for transporting small loads.

Trailer with open sides PHOTO: sadovaja-tehnika.com

Trailer with a seat for a mechanic PHOTO: ufa.rostrakt.ru

Related article:

The most reliable and popular cultivators and walk-behind tractors : varieties and average prices, a review of popular brands, the secrets of choosing the right device for a summer house and garden - in our publication.

Do-it-yourself tow hitch for a walk-behind tractor

You can buy almost everything now. But it’s much more interesting, and sometimes more effective, to make the right thing with your own hands.

Required materials and tools

For work you will need metal pipes: round and profile, with dimensions 60×30 mm and 25×25 mm², various rolled steel - angle, channel, rod. You will need a metal sheet. Depending on what you can get, you need to adjust the preliminary dimensions in the drawing.

It is almost impossible to make complex parts, for example, the chassis of a trailer, in a garage. It is better to take them from decommissioned branded products. For example, for this trailer unit you can take suspension elements from a Zaporozhets or an old Moskvich. Of course, the mechanism will have to be sorted out, repaired and reassembled. But a craftsman can already do this.

Blanks for the frame PHOTO: youtube.com

To work, you need a good set of plumbing tools - a workbench, a vice, a drilling machine and an electric drill, hammers, files, drills, pliers, wrenches, a screwdriver, a hacksaw, a grinder, and screwdrivers. It's good to have access to a lathe. You must be proficient in electric welding techniques.

Drawings with dimensions for a trailer to a walk-behind tractor

The creation of a set of design documentation (CD) is the beginning of any work to create a complex product. The peculiarity of the work of a do-it-yourselfer is that his material capabilities do not always coincide with his creative desires. Therefore, it is sometimes premature to make detailed detailed drawings. But a general view drawing showing the entire structure and its approximate dimensions needs to be developed. During the work, adjustments will be made to the real capabilities of the master.

Trailer assembly drawing PHOTO: koffkindom.ru

Why exactly a log?

First, let's find out what a rounded log is and why the vast majority of people prefer to build housing from it.

Important: speaking in the dry language of definitions, a rounded log is usually called a straight tree trunk, pre-processed on woodworking machines to give it the correct cylindrical shape. As a result, the top uneven layer and knots are removed, and compensation and mounting grooves are applied.

Scheme of a rounded log.

Advantages of the material

- Wood itself has a natural porous structure, as a result of which it is one of the best heat and sound insulators.

- Having clear geometric dimensions, this material fits perfectly together. Specially designed grooves ensure high tightness and quality of inter-crown seams.

- All trunks have a clearly fixed diameter; the maximum deviation here can be no more than 2 mm. This makes it possible to select scaffolding for the construction of premises for various purposes with specified characteristics.

- At the moment, there is simply no building material that is more environmentally friendly and beneficial for people. Unlike wood, traditional brick or modern types of building materials can only boast of environmental neutrality.

Product calibration.

- Although the price of rounded logs may be higher than that of many competitors, such houses do not require additional internal and external cladding. This material itself has natural beauty, as a result of which owners save significantly on finishing.

- Modern woodworking equipment makes it possible to initially produce trunks with ready-made connecting elements. This significantly speeds up the construction process and gives a lot of layout options.

Layout diagram.

- You may have already heard that natural wood breathes. This means the ability of the array to take excess moisture from the air and release it when conditions change. Simply put, wood is a natural air conditioner, providing an ideal microclimate for human life in the house.

- And finally, the construction instructions are quite accessible. A good owner, with a strong desire, can build a simple bathhouse, barn or small country house with his own hands.

Some product characteristics.

What are the disadvantages

- As we have already said, wood is a living material, so over time the wood begins to dry out and crack. This is true, but thanks to modern impregnations and primers for wood, such processes can be significantly slowed down.

- Many people know that during the process of growth, a tree trunk slightly twists in a spiral. After the cut, this spiral sometimes begins to unwind. This is why craftsmen do not recommend building from freshly cut timber; the structure may fail. But a dry rounded log does not have this drawback.

- Disadvantages such as high fire hazard and susceptibility to biological pests are easily eliminated using the same specialized impregnations.

- Perhaps the only significant drawback of any wooden structure is the high percentage of shrinkage of new houses. Well-dried, high-quality wood shrinks up to 100 mm for every 3 - 4 m of wall in the first year. And 10 - 20 mm each for another 2 - 3 years. Freshly cut timber will take up to 10 years to shrink.

Log structure.

Making a homemade trailer for a walk-behind tractor with your own hands

The technology for creating any machine is approximately the same. First, all the parts are made, then assembly begins.

Housing frame

You need to start by making a frame, to which, in the process of making other parts, you should try them on and see how the entire product is assembled. As a rule, this is a rectangular product with dimensions of about 1500x1000 mm.

Chassis

Experts believe that the most reasonable thing is to take the rear axle from a decommissioned small car, for example, Tavria. Of course, you need to go through, wash and lubricate all the moving elements.

Chassis PHOTO: koffkindom.ru

Body, frame trim

A trailer is made so that something can be transported in it. This means you need a small body. The frame is already there, you need to make the sides. They can be made of wood, plastic, or corrugated sheets. Wood is short-lived, plastic has low strength, metal is more expensive, but will last much longer. If the sides are made of steel sheet, then they must be reinforced with stiffeners. Wooden sides must be treated with a special impregnation to prevent rotting. It is recommended to make the tailgate opening.

Do-it-yourself trailer brakes for a walk-behind tractor

Any vehicle must have a brake. And the hitch of a walk-behind tractor and a trailer is a vehicle. Of course, you can’t drive it on city streets, but for your own safety you still need to install a brake. The mechanism shown in the figure below is operated by a foot pedal. When parked, the device is secured with a furniture latch. If possible, you can install real car brakes.

Trailer brake option PHOTO: youtube.com

Other details

The most popular “other part” is the mechanic’s seat, and sometimes also the passenger’s seat. The degree of comfort provided depends on the taste and ingenuity of the designer. And another useful detail is a parking stand for the trailer beam. When parked, this device is folded down and the trailer is in a horizontal position.

What affects performance

To determine the basic parameters of the material, there is a set of regulations. In our country this is GOST 2708-75, in the west ISO 4480-83. There is no big difference between them, the main parameters are identical. It is on this data that a program such as a calculator for rounded logs of volume, weight, density and other characteristics is based.

Array volume table.

Advice: it is desirable that the table of volume of rounded logs be original, that is, taken from the above-mentioned regulatory documents. Since now there are many corporate tables compiled taking into account the commercial interests of some corporations and containing inaccuracies that are beneficial specifically for those who compiled them.

Machines and equipment

Even 50 - 100 years ago, every carpenter or just a good owner knew how to round a log at home. Due to the fact that this occupation is long and very labor-intensive, with the development of woodworking production there are not many real specialists left.

Of course, in the debate about whether a log or a rounded log is cheaper, an ordinary unprocessed trunk wins. But building a good house or a high-quality bathhouse from “wild” material is almost impossible. Apart from the time spent on handicraft cylindering and labor-intensive installation, you will not be able to seal the seams and joints hermetically. Accordingly, the room will be cold and will not last long.

A machine for cylindering logs is, in fact, a symbiosis of milling and turning functions. Such equipment has impressive dimensions and includes a common metal frame on which they are based, a power unit, which can consist of several power units.

The main work is done by the headstock. It is on it that cutters for stripping the top layer and figured cutters for finishing the log are installed. The tailstock, as in most similar equipment, serves to fix and feed the workpiece itself.

If you want to know how long it takes to make a rounded log, then in this case it depends on the quality and functionality of the equipment. Modern automated lines are capable of turning a high-quality calibrated product from natural logs in a matter of minutes, according to specified parameters.

All such units come in two types - continuous and cyclic. The first ones are designed for large production volumes and have a minimum of functions. In them, the material moves in a continuous flow and, passing through the working area, is cylindered and milled.

Installing the workpiece on the machine.

Aggregates of the cyclic type perform a given algorithm of actions, after which the cycle is repeated. They, in turn, are divided into cyclo-pass type, where the barrel moves and the carriages are in a fixed position. And cyclo-positional, where the log is motionless and the carriages move around the workpiece.

As a rule, a do-it-yourself machine for a cylindrical log is made on the basis of a sawmill, where a stop is installed instead of the front cone, and the tailstock is replaced with a bearing or a rotating cone. The workpiece secured in this way rotates due to an additional drive or with your own hands, which is very difficult and inconvenient.

Processing is carried out by a milling head mounted on separate guides. The very principle of operation of such a handicraft unit is reminiscent of the operation of a wood milling machine. A rotating workpiece is gradually processed by a milling cutter moving along guides.

Advice: due to the serious weight of the workpieces themselves, experts recommend rigidly mounting such equipment exclusively on a concrete base. If this is not available, as an option, you can lay a reinforced concrete slab for the floor.

General diagram of the machine.

A few words about the characteristics

Domestic production is more focused on the so-called lunar profile of rounded logs. It contains a mounting cup for connecting the crowns and a compensation cut.

This cut serves to compensate for the natural internal stress of the array, as well as temperature and humidity expansion. Such a product is cheaper to manufacture, plus it does not require careful preliminary preparation of the material.

The Finnish profile provides a tighter connection of the crowns; therefore, less sealing materials are needed, but the log requires careful drying and preparation, as a result the price of the Finnish profile is higher.

The working height of the rounded log is 6 meters. This does not mean that products cannot be larger or smaller.

It’s just that most technological lines are oriented towards this size. An increase in height entails an increase in cost. The price of smaller barrels depends on the quality and complexity of processing of a particular product.

Storing goods in stacks.

As for the diameter, the working range here ranges from 160 to 320 mm. Rounded logs of 400 mm or more are processed on special machines. Such non-standard goods are used to equip the main crowns of the building, as well as other important load-bearing units. In addition, the walls of the first floors for multi-storey cottages are sometimes erected from logs with a cross-section of 400 mm.

The cost of the product is greatly influenced by the method of drying the massif. Natural drying takes place for about six months under open sheds in natural conditions. Such a product costs less, but its shrinkage is higher.

Chamber drying involves processing the material in special high-temperature chambers. Such a log shrinks less and is considered to be of higher quality.

Important: glued rounded logs appeared on the market relatively recently. The price for such products is much higher. But, according to experts, they are of exceptional quality.

The video in this article contains materials on this topic.

Self-production of a hitch for a walk-behind tractor

There are many options for couplings. This mechanism is needed not only for securing the trailer. With its help, any attachments can be installed on the walk-behind tractor. The best option is a knot, when a pipe is connected to another pipe. One of the simplest, but quite reliable devices is shown in the photo.

Hitch PHOTO: youtube.com

Hitch drawings for a do-it-yourself walk-behind tractor

The design of parts of one of the coupling device options is shown in the photo.

Hitch assembly PHOTO: specmahina.ru

How to make a hitch for a walk-behind tractor trailer

Two brackets, cut from the channels, are attached to the parts of the trailer and walk-behind tractor. Holes for fastening with bolts are drilled in the cut brackets. An adjusting screw with a handle is installed on the side of the walk-behind tractor to make it convenient to hook up various attachments.

Longitudinal movement of the log

If it is necessary to move the log along its axis a short distance, use a crowbar or a pipe with a flattened end. The lever is driven into the ground under the end with an inclination in the opposite direction of approximately 45 degrees. By pressing the lever on the end, push the log forward 25-30 cm.

This result can be achieved in another way. Throw the first loop of short rope or cable over the front end, and the second loop over the crowbar below its middle. Lightly drive the crowbar into the ground at an acute angle towards the log. Lean on the lever, and the log will willingly move forward. If you need to move it in the longitudinal direction by 1-2 cm, just hit the end well with a sledgehammer and you will get the desired result. This technique is often used when the log is on a log house.

If you need to turn a log lying on the ground, say, perpendicular to its position, do this again with the help of a crowbar. It is slipped under the front end and pushed in the desired direction. To hold the second end of the log in place, a light pipe or just a small peg is driven in front of it.

The nuances of manufacturing other types of trailers for agricultural machinery

Let's look at the basic blocks that need to be used to create functional equipment.

DIY cultivator trailer

A cultivator is a device for cultivating soil. A motor-cultivator has its own engine, the cultivator simply takes power from another device, for example, from a walk-behind tractor, which, therefore, must have a power take-off device, and the cultivator itself must be able to receive this power. This function is not present on all models of walk-behind tractors and cultivators.

But there are also passive attachments for the walk-behind tractor, which do not require power take-off. Samples and standard coupling are shown in the photo. If the hitch was not included in the sales package, then it can be made as described in this article.

Attachments for walk-behind tractor PHOTO: ok.ru

How to make a two-axle trailer for a walk-behind tractor

To transport cargo over 300 kg, a two-axle trailer should be made. The technology for creating it is the same as for a single-axis one - development of design documentation, selection of materials and suitable parts, manufacturing of parts and frames. Since the vehicle is designed for a large load capacity, the frame must be made more durable. It will require profile pipes measuring at least 50×50 mm². The wheel axles are welded to the frame side members.

Frame for a two-axle trailer PHOTO: traktoramira.ru

An interesting option is obtained when the walk-behind tractor is placed behind the loading platform. This layout resembles an ATV. During the process of testing and modification, the front part of this miracle machine was equipped with a steering column with all the necessary mechanisms. The result was a self-running stroller. And you can attach a cargo trolley to the back of it.

Tipper trailer for walk-behind tractor

The peculiarity of a dump trailer is that its body is not welded to the trailer platform, but is mounted on a hinge. The center of gravity of the loaded body should be slightly behind the hinge. The tailgate must be folding or removable. The manufacturing technology is the same as for other designs.

From history to modern production

The instrument was once like this.

Bagry appeared a long time ago, when the first tree was cut down and floated down the river to its destination. With the help of this pole with a metal attachment in the form of a lance and a hook, the log was dragged to the river, lowered into the water, and the material was met with exactly the same hooks at point B.

Not much has changed since then. Currently, hooks can be divided into two types:

- Fire hook for logs. It is he who most closely resembles his ancestors, the same lance and the same hook at the end. In addition, it can be completely metal;

- Hook for turning logs. This device has a slightly modified design. The hook is movable and can grip a log of a certain diameter. In this case, the peak is replaced with a platform called the heel, which supports the log from the diametrically opposite side. For convenience, a perpendicular platform for support can be installed at the end of the hook.

These are modern products.

Modern industry produces hooks of a slightly modified design, externally reminiscent of axes and with a highly specialized application - specifically for turning.

- There is a small log tilter - a hook up to 40 cm. It is made of durable steel and its main purpose is to work with small logs of light weight;

- The hook for turning logs is large - it is designed for large logs.

For your information! The small tilter can be replaced with an ordinary ax, and although this is strictly prohibited due to safety regulations, small logs that are mainly used for splitting can be safely carried with your own hands to the splitting site, or, as a last resort, you can take a wheelbarrow.

Needed or not needed?

Turning a large log.

To answer this question, let’s look at its application:

- A tilter is necessary if you have your own sawmill and are professionally involved in carpentry work. In this case, you will have several of them, taking into account different diameters of logs, as well as different designs;

- If you have a large farm and many operations, including the preparation of firewood, are carried out by you yourself;

- If you make money from logging.

In all other cases, I think you will not need it.

Questions and answers

The tool cannot be replaced.

The inquisitive mind of our man is trying to find a replacement for many things from cheaper material. The attempt to replace purchased gaffs with home-made analogues is understandable. Anyone who wants to pay from 2 to 6 thousand for this invention can do it themselves.

But a person goes even further and tries to replace the tilters, for example, with ropes, motivating his decision by the fact that ropes can withstand significant weight and will have to be dragged in both cases.

Let's try to understand the feasibility of these replacements:

- The forest is different from the forest. When cutting wood for carpentry production, the following are usually taken into account:

- Season . This indicator is very important, since the weight of a tree during felling in February will be 15% less on average than the weight of wood in autumn or spring;

Seasonality affects the weight of materials.

- Condition of groundwater. If the forest is taken from an area where water is very close to the soil in swampy areas, then be prepared for the fact that, regardless of the timing of felling, you will receive a sponge saturated with moisture, and there will be a maximum amount of it in the lower part of the tree;

- Type of harvested wood. It is known that coniferous species are heavier than deciduous ones due to the presence of resinous substances. However, if resin was previously collected in such a forest, then such wood will be 1.5 times lighter than untouched wood;

- From the characteristics of the climate. This refers to humidity. If the average annual level is high enough, then the wood will be heavier.

Procuring material is a responsible job!

Types of trailers for walk-behind tractors

Making a cart for a walk-behind tractor or a trailer with your own hands does not present any difficulties if you have the desire, the necessary tools and experience in such matters. The design of such mechanisms itself depends on the purpose and load capacity. Naturally, the heavier the load you plan to carry, the more complex the trailer will be. The schematic drawing shows the main components.

With unibody

For light and medium categories of walk-behind tractors, single-axle trailers with a body size of approximately 140×100 cm are made. Their sides and bottom are fixedly . This is the simplest design, with a load capacity of up to 350 kg. To speed up assembly, the body is often made rigid - without shock absorbers.

Those who have made a walk-behind tractor with their own hands from the rear axle of a VAZ know very well that the wheels for such a cart can be taken not only from Zhiguli cars. The bridge from Moskvich is also suitable for these purposes .

It already has ready-made springs, lugs and earrings. All that remains is to weld the main frame from corrugated pipe, which is mounted on springs . Then weld the racks for the sides, build the carrier and install the towbar. As a result, the cart body is ready.

With folding sides

homemade log hauler

While the frame of the band sawmill and the rails have not been welded, I decided to make a cart for transporting logs with my own hands.

Timber truck for walk-behind tractor.

Log hauler

MOTOR-BLOCK NEVA TIMBER.

Hello, friends! Alexander Churkin is with you! We are going after a log on a Neva MB 23 walk-behind tractor with Volgov wheels.

Drive overpass, piece delivery, log hauler, dumper

Manufacturing of woodworking and machine tools.

A horse in arable land is POWER.

Plowing a garden with a horse is quite an interesting agricultural technique. This is how those who have a horse plow the soil in our village.

Log hauler and log dumper

Turning over a log using a grandfather - a hook

Instructions for assembling and installing a Taiga band sawmill with a Honda gx 390 gasoline engine, Device.

Mechanical resetter.

Mechanical resetter. IP Neganov Nikolay Viktorovich Design and manufacturing to order.

DIY simplest (wheelbarrow) LOG TROLLEY without a winch)!

Homemade skidding grip from Vikor Mironov.