They haven’t written any jokes about instant glue with soda, but everyone is silent about one interesting feature. So, a mixture of cyanoacrylate and soda instantly polymerizes (hardens), releasing heat and perfectly bonding with molecular bonds to nearby layers. But not with just anyone. With ABS plastic it’s good, but with polypropylene it’s bad. Well, so what? When filling layer by layer (more precisely, “ order

pke") maintaining the exact shape of the part is not easy. A lot of excess has to be removed mechanically (with a file) at the end. What about “formwork” made from the same available materials? Homemade 3D printing from your pocket.

I once broke an armrest in a car. I had it for six months, lying there (I thought I’d print a new one, yeah), until I came across repairing the monitor with soda. Having estimated the cost of replacing the armrest (only together with the entire console), I decided to buy a tool with this money. The “officials” would probably have enough for a whole workshop.

It is noteworthy that it was at this moment that I learned about photo-curing BONDIC adhesive, but more on that later.

Interaction mechanism

Superglue has been produced since the 50s. It contains cyanoacrylate, and there are no solvents in the glue. Superglue hardens instantly, so the product is often used in emergency situations. Most often, the glue is one-component, sold in one bottle. They will not be able to glue large surfaces due to the high setting speed. Superglue also comes in two components:

- the first tube is the glue itself;

- the second is an alkaline agent.

When the contents of the tubes are combined, an adhesive mass is obtained that has special strength characteristics. The principle of combining cyanoacrylates and baking soda is based on the ability to react to the introduction of alkalis. Under the influence of a weak alkali, the liquid monomer instantly sets - a polymerization reaction occurs. The finished substance resembles acrylic in appearance and properties. Due to its similarity to plastic, the superglue plus baking soda combination is most often used to repair plastic products.

During polymerization, elevated temperatures are generated. This increases the degree of adhesion; as a result, the fixation with the part will be even higher. The composition is so strong that it can be used to glue plastic to complex materials, fill defects and cracks, and restore worn areas in mechanisms. Using glue with soda will be useful for computer engineers, car enthusiasts, and will also be useful in everyday life.

Why else is instantaneity needed?

It is precisely its immediacy, it seems to me, that attracts the above-mentioned BONDIC.

Human laziness and impatience are a great sales driver. A handheld 3D printer in your pocket. But let's get back to soda. I had to drill a thin hole twice the length of the drill itself, and even with the drill stand I bought, it's not as easy as it looks. Again I remember the joke about two tunnels. This is where the main property appears: the rate of polymerization. Missed? No problem, we carefully “bury” the hole back, adjust the drilling rig and drill again, luckily everything hardens instantly. Not every material forgives mistakes so quickly and easily.

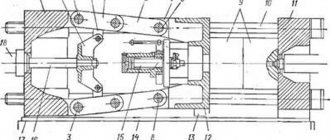

By the way, about the stand for the drill KWB Profi 7778-00.

The backlashes are really removed, a powerful cast rod, a new level of processing materials at home, delight! And the silumin frame spoils the effect :-) True, to drill my part I had to borrow for a couple of days from a DIY supermarket this add-on made of 5mm steel, used for fastening house beams (and what, you don’t even need to drill holes): almost free add-on

sorry for the quality

Instructions for using the mixture for repair

Bonding products with cyanoacrylate glue and sodium bicarbonate will help in many types of repairs. The mixture can hold broken parts together, fill a chip, repair a machine screw and similar replacement parts. There are a number of rules for gluing products during the repair process:

- take a suitable abrasive, clean both surfaces of the products (this will help remove dirt and open small pores into which the adhesive mass will penetrate);

- moisten a cloth with alcohol or solvent, degrease the surfaces (otherwise the fats may cause the material to peel off);

- pour baking soda into the defect or sprinkle it on the surface;

- pour soda with glue;

- connect the parts as quickly as possible (if required);

- blow off the remaining soda;

- After 15 minutes, you can begin grinding, polishing, and other actions with the resulting adhesive seam.

What can baking soda with superglue do?

Now you know what baking soda and superglue can do, but how to do everything so that the process is successful? Let's look at a few standard situations.

We repair the bumper

The appearance of a crack on the bumper is not yet a reason to rush to the workshop when superglue and soda are at hand.

First, remove the bumper itself. Then use a drill to make holes along the edges of the crack to prevent it from spreading. Next, to clean the “field of activity”, go over the surface with an abrasive material; sandpaper will cope with this mission perfectly. The final stage: prepare the components, pour a layer of soda onto the treated crack, and apply superglue on top of the powder. After the chemical reaction has passed, take a half-hour break and continue processing the seam using the same sandpaper.

You can try to glue a cracked bumper yourself

Filling the cavity

Thanks to the strongest connection, the recipe is also applicable for those cases when it is necessary to fill dents and damage caused by wear and tear of the product. To fill the depressions, the interaction of soda with glue must be of a different nature, although the technology remains the same. You can skip the step of treating the surface with sandpaper; just degrease the surface thoroughly using an alcohol-containing product. Then carefully fill the cavity with sodium bicarbonate, and generously sprinkle the powder with superglue on top so that the dry mass is completely saturated. And in half an hour the “finest hour” of sandpaper will come, with the help of which you will have to level the surface so that it is no different from the factory one - with due diligence this is achievable

Restoring the figured part of the part

Choose medium-grit sandpaper

Sometimes it is necessary not only to connect the surfaces of products, but also to “grow” a broken piece of plastic. For example, quite often fasteners, blades and other small “spare parts” are worn out, broken, crumbling into small parts, or even lost in plastic products.

In the restoration process, you will have to use the makings of a sculptor and artist, since the process will have to be divided into several stages. Apply components in small portions, recreating the missing “spare parts” gradually - stroke by stroke. The glue is applied literally drop by drop, each of which is sprinkled with soda and after a few seconds it is adjusted to the desired shape with sandpaper. Only after treatment can the next drop be applied.

If for the first time you go too far with the size or shape of the part being restored, do not worry: abrasive materials can remove the entire incorrectly applied layer. When you see that you have recreated the shape of the missing fragment, but there are inaccuracies in the relief, the surface is not smooth enough, do not rush. Give the final version of your “creation” at least an hour to dry completely before adding the finishing touches.

Gluing plastic

And finally, let’s talk about the most common gluing method – standard restoration.

Baking soda and glue can glue broken parts together

Step-by-step instruction:

Step 1. Free the surfaces of the parts from roughness that may impede the penetration of components, which will lead to a decrease in the strength of the seam. The best assistant in such matters is sandpaper. However, choose this abrasive material that is not the coarsest grit, otherwise you will increase the roughness rather than smooth it.

Step 2. Degreasing. Again, to increase the strength of the connection, clean the parts, since grease and other contaminants cause the appearance of air pores, which will negatively affect the process. Any product containing alcohol is suitable.

Step 3. Gluing. Apply glue to the planes and connect them, then sprinkle the seam with soda. Don’t skimp on the powder, it will be absorbed gradually, and you can always blow off the excess.

Step 4: Polishing. After a quarter of an hour, sand the seam. This way you will achieve the most even connection, which may even become invisible to the eye.

Baking soda and superglue are substances available to everyone that work wonders when gluing.

Using cleaning adhesive

In apartments you often find old cooking utensils, for example, cast iron frying pans and pots. Over the years, soot and hardened fat particles accumulate on them outside. There is a method that allows you to quickly get rid of dirt using improvised means. In this case, you need to use silicate glue, baking soda, and laundry soap. The finished product will be even more effective if you use soda ash instead of baking soda.

Instructions for use are as follows:

- take a large container and fill it with water;

- put on fire, let the water boil;

- grate a bar of soap, throw the flakes into the water, stir;

- Reduce heat, leaving a slow simmer;

- pour in 100 ml of silicate glue, pour in a glass of soda;

- immediately open the window for good ventilation of the room (it is better to carry out the cleaning procedure using household gas in an open veranda);

- lower the contaminated dishes into the solution, after removing the plastic parts;

- boil for about an hour, then turn off the heat;

- leave the dishes in the water for another 2-3 hours.

After the specified time, you can take out a saucepan or frying pan and easily clean the carbon deposits using a scraper or aluminum sponge. After finishing work, rinse the dishes with clean water. This method is only suitable for metal products; it is absolutely not suitable for plastic!

Home repairs

To repair various products, you need to prepare baking soda and superglue. Some people believe that any bulk substance is suitable instead of soda, but this is incorrect. You can replace baking soda with caustic or other alkalis, but it is better not to experiment.

Bumper repair

Car bumpers are made from modern thermoplastics, thermosetting plastics, so they can be repaired using adhesive mass. Minor chips and defects can be eliminated without contacting a car service. Typically, such repairs are carried out for internal chips.

First, you should remove the bumper from the car and clean it of dirt and deposits using fine sandpaper. Next, you need to wipe the damaged area with an organic solvent (acetone, white spirit), and fill the defect with superglue. Then pour baking soda directly onto the superglue and repeat several times using small portions of the powder. To achieve maximum strength, leave the product without moving for 30 minutes. Afterwards, the excess composition must be removed, the part must be sanded and polished. In addition to the bumper, this method can be used to repair armrests, headlights, and other plastic car parts.

Monitor repair

Monitor failures often occur due to damage to the stand. This happens when the object is handled carelessly, as well as when the design is poorly thought out, when the weight of the display does not correspond to the weight of the fastening sleeve. Epoxy may not be suitable for repairs as it is more suitable for bonding metal. You can repair the product with superglue and soda. The instructions are:

- remove all fragments so that there are no weak connections left;

- clean the area with sandpaper to enlarge the pores;

- degrease the surface with alcohol;

- sprinkle the edges of the crack with sodium bicarbonate;

- pour superglue liberally into the powder;

- after final hardening, brush off excess soda and treat the area;

- carefully sand the “patch”;

- drill new holes for screws;

- reassemble the structure;

- if necessary, paint the white patch with dark acrylic paint.

Filling the cavity

Superglue and baking soda in combination are an excellent tool for filling cavities formed during a breakdown or impact. This mass can also eliminate unnecessary recesses and depressions on various products. Before such a mini-repair, plastic is not sanded; it is quite easy to treat it with alcohol. All other materials should be sanded to improve adhesion.

First, the required amount of soda is poured into the cavity. Next, use superglue - add it drop by drop, soaking the soda well. It is important that a sufficient amount of superglue is immediately available, otherwise there will not be enough of it. It is better to fill large cavities layer by layer, because dry soda may remain at the bottom, which will greatly reduce the quality of the repair. Cleaning and polishing of the new surface is allowed after 20-30 minutes.

Restoring the figured part of a part

You can use a mixture of superglue and soda not only to level the surface or glue parts, but also to restore the desired relief of products. This is usually required when blades or clamps in various mechanisms or devices break. The operating procedure will be similar at first - cleaning, degreasing. Afterwards, you need to apply glue to the base in small portions and carefully sprinkle it with soda powder, without missing a drop. You need to repeat the steps until the desired relief of the product is formed. More mass may have to be placed in some areas than others. Grinding and polishing will help to finally give the product the desired look.

Bonding plastic

How to glue two parts together if they are made of plastic? You can also use superglue and baking soda. Be sure to do cleaning to remove dirt and open micropores. Afterwards, the parts must be degreased with an alcohol-containing liquid. Next, apply a thin layer of glue, sprinkle with soda and instantly press the second part. After 20 minutes the product can be used.

Features of superglue

In Russia, people learned about superglue relatively recently.

This substance was invented back in 1942, but at first they were biased towards the invention of the American author, not seeing anything special in it. Only 10 years later, superglue became a part of American life and began to be used for various purposes. When the first tubes arrived in our region, they sold out very quickly among local residents. What is so special about superglue? It is based on cyanoacrylates, derivatives of cyanoacrylic acid. The composition does not contain any solvents, so it hardens instantly.

There are several types of superglue, which differ from each other in composition and spectrum of action. These include:

- One-component. This product is most often offered in regular stores. It consists of one tube of ethyl cyanoacrylate. It usually takes 24 hours for superglue to fully take effect. Although it sticks almost immediately, throughout this time the glue components remain active. Feature of one-component

- superglue is that it hardens very quickly. On the one hand, this is good, but when it is necessary to glue two large surfaces, such a product will not be enough. Therefore, the scope of application of one-component superglue is very limited.

- Two-component. Consists of two tubes with different fillings. The first contains the glue itself, and the second contains the alkaline agent. In order to use the product, the contents of both tubes must be mixed. Then, for two minutes, you need to quickly process the edges of the surfaces that need to be glued, connect them, pressing them tightly against each other, and hold for a few seconds. The peculiarity of two-component superglue is that using just a tube of the glue itself will not bring any results.

Precautionary measures

Polymerization of the adhesive mass occurs in literally 3 seconds, so you need to work very quickly. You should wear gloves, otherwise your fingers may stick together, which can cause skin damage. If glue gets on an unintended surface, you must immediately remove it by dissolving it with acetone.

Proceed in the same way when gluing the skin: apply a cotton ball moistened with acetone for half an hour, then remove the dissolved mass. To avoid pouring too much baking soda, it is better to do this using a small funnel or take the powder literally a pinch at a time. It is important to ensure good ventilation in the room to avoid poisoning by cyanoacrylate vapors.