Reciprocating cutter for paper and other materials

There are three main types of paper cutters: roller, guillotine and reciprocating.

It is the manufacture of the latter type of cutter that we will consider in this material. Tools and materials: -Boards; -Metal corner; -Old hacksaw; -Plywood; -Capacity; -Water; -Lemon acid; -Brush; -Roulette; -Pencil; -Hacksaw; -Vise; -Drill; -Screwdriver; - Fasteners; -Milling machine; -Manual frezer; -Carpentry glue; - angle grinder; -Cutting disc; -Petal disk; -Clamps; - Belt grinding machine; -Sharpening machine; -Metal ruler; -Chisel; -Hacksaw for metal; -Aluminum profile; -Wooden ruler; - Angle; -Stationery knife; -Wood burner or soldering iron; -Protractor; - Furniture varnish;

- Rags; -Wood crowns; -Drilling machine; -Feather drill; -Rubber; - Drying oil;

Step one: cleaning metal parts In his homemade product, the master uses several old metal parts covered with rust. To clean the parts, he places them in a container, fills them with water and stirs citric acid in the water. After a few days, the acid will eat away the rust and the parts will need to be brushed and washed. Step two: frame The frame is made of four bars. The frame size is larger than A4 format. One block protrudes beyond the frame; a knife will be attached to it. The bars are connected using the tongue-and-groove method and fixed with wood glue and screws. The mortise-tenon joints are made using a milling machine. I processed the corners and sanded the frame. Covered with drying oil.

Step three: work table The working surface of the table is made of 6 mm thick plywood. The plywood is screwed to the frame. The plywood is screwed down and the craftsman mills the edge of the work table. A plywood cover is glued onto the protruding part of the frame. Step four: counter knife The counter knife master made a corner. The worker made a groove along the width and thickness of the corner. The corner itself was cleaned of rust and shells, and mounting holes were drilled. Ideally, the knife and counter-knife should be made of the same brand of metal, but the master does not often use a cutter and a corner will be enough for his purposes. It is also important that the angle of the counter knife is even. Step five: knife The master made the blades of the knife from hacksaw blade. I cut off the part with the teeth and sanded the blade. Makes three longitudinal cuts on the side opposite to the blade. Thanks to them, it will be possible to adjust the blade extension. The blade holder is made of oak board. A cut is made in the lower part along the entire length of the knife. The plane of the holder to which the blade will be attached must be sanded from the middle to the edges. More material is removed from the middle and less towards the edges. This will create an effect similar to scissors, with the blades slightly bent towards each other. Now you need to secure the knife to the holder. Marks mounting holes. Drills holes. Pre-screws the knife to the holder. Drill holes for the mounting bolt in the corner and protruding part of the frame. Step six: stop and measuring ruler The stop is made of an aluminum profile; a regular wooden ruler is used as a measuring ruler. Mounting holes were drilled in the profile. Markings along the width of the ruler were applied on the desktop. Using a milling cutter and chisel, a groove for the ruler was selected. Polishes the surface of the desktop.

Combines the edge of the counter knife and the 0 ruler. Cuts off the protruding part. The ruler will be attached to two screws. The stop must be secured at right angles to the counter knife. Step seven: marking The master applies markings in two coordinates. One, from the counter knife along the work table, in increments of 1 centimeter, the second from the corner, a measuring ruler - stop - counter knife, in increments of 15 degrees. After marking, he burns the lines with a burner and a soldering iron.

Step eight: protective coating To protect the desktop, cover it with furniture varnish. Step nine: legs The master made the legs from rubber. I drilled holes in the rubber and cut them out with a wood saw. Sanded it. I screwed the legs to the frame.

Step ten: finishing the knife Sharpen the cutting edge of the knife.

Makes a small semi-circular cut for the thrust bolt. Covers the handle with varnish.

Screws the knife to the base. Screws the stop bolt into the base. The following photo shows the results of testing the cutter. The following materials are presented: paper, corrugated cardboard, plastic bottle, aluminum can and rubber. Source Delivery of new homemade products to the post office

Receive a selection of new homemade products by email. No spam, only useful ideas!

*By filling out the form you agree to the processing of personal data

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

usamodelkina.ru

Homemade paper cutter. How to make a sandpaper cutter

The presented guillotine, made by hand, works on the principle of lever shears and is designed for cutting sheet metal with a thickness of no more than 3 mm.

It is made from improvised materials, in particular from an old file and scraps of metal structures.

Manufacturing a guillotine consists of several stages. First, it is necessary to carry out drawing work in order to accurately determine the dimensions of the product. The applied scale is 1:1.

It is also recommended to draw a kinematic diagram, with the help of which it will be possible to determine the dynamic parameters of moving parts without taking into account the acting forces.

Drawings of parts drawn on paper are printed on a printer and then cut out. The machine model is assembled from the cut out parts. This is done in order to verify the correctness of the calculations made and the exact correspondence of the dimensions of each individual component in the context of the functioning of the entire mechanism as a whole.

It is very important to determine the cut level indicator. It will be located at the intersection of the movable blade with the base, which is conventionally indicated by a line drawn in pencil.

The next step is to select pieces of scrap metal of suitable size, followed by template drawing of the contours of future components on them. It is at this moment that the paper scraps from under the animation turn into an important stencil.

In this case, the blanks were scraps of a corner and a sheet piece of iron lying around. And as a result of intensive work with a grinder or a gas cutter, the main parts of the metal scissors were obtained. These are two ears, a handle, a body holder and the body itself.

A base of two welded corners is attached to the body of the guillotine. Their thickness is 50 mm. Pay attention to the space taken into account for entries in the mode: “sheet up”, “sheet down”. There is also free space for a file. In this case, one must proceed from the parameters of its thickness plus the required gap.

Then, with the help of mounting bolts, a sequential assembly process occurs. The handle is attached to the main structure of the scissors through two ears. After which one end of the body holder is screwed to it. The second one is connected to the handle.

The result should be something like this. Provided that no mistakes were made in the previous stages, the moment of complete cutting should occur when the handle reaches a horizontal position. The minimum movement of the handle against the background of the maximum stroke along the radius must also be achieved.

The blank for the two blades was an ordinary old, and therefore ground, file. To begin with, it should be cut into two parts. Three holes are drilled in each of them for fastening. After this, the blade profile is formed and the edges are directly sharpened.

The images show where the two cutting knives are attached. The movement of the upper knife should not be obstructed by other parts of the machine. It is important to position the profile in such a way that across the entire width of the cut, the interaction of the knives occurs at an angle of 6-8 degrees.

Ready-to-use homemade lever scissors are securely fixed to the working surface of the workbench using clamps or specially drilled holes.

Provided that basic technological rules are observed during the manufacture of the machine, it will certainly show very high efficiency. And it will cut both paper sheets and 3mm iron with ease.

Video: DIY manual guillotine for cutting metal.

Paper cutter

- a device for quickly and smoothly cutting paper. Very useful when designing scrap pages and postcards. The cutter allows you to cut a sheet of paper so smoothly that no scissors can cut it.

According to the method of impact on the knife, cutters are divided into mechanical (manual) and electric. In turn, hand cutters come in roller, saber and guillotine types.

Roller cutter

(also known as a disk cutter or trimmer) is a rectangular base (work table), along which the cutting mechanism moves along a guide. It, in turn, consists of a sharpened metal disk enclosed in a protective casing. When cutting, the paper ends up between the roller cutter blade and the counter knife (a hard metal plate attached to the end of the platform on the side where the cutter moves). This cutter is ideal for working with a small amount of paper - up to 10 sheets, it comes in different sizes, the most common are 22.5 x 12.5 cm; 31 x 31 cm; 20 x 46 cm. It takes up little space and has a valuable quality - the ability to cut an edge less than a millimeter wide, which allows you to work with maximum precision. In roller cutters, the knives are not subject to secondary sharpening, although they are called self-sharpening. They just need to be changed after a certain time.

Reciprocating cutter

calls

levevg.ru

Do-it-yourself photo cutter - Metalist's Handbook

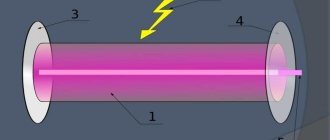

Laser cutting is the most advanced, but also expensive technology. But with its help you can achieve results that are beyond the power of other metal processing methods. The ability of laser beams to give any material the desired shape is truly limitless.

The unique capabilities of the laser are based on the following characteristics:

- Clear directionality - due to the ideal directionality of the laser beam, the energy is focused at the point of impact with a minimum of losses,

- Monochromaticity - the laser beam has a fixed wavelength and a constant frequency. This allows it to be focused with ordinary lenses,

- Coherence – laser beams have a high level of coherence, so their resonant vibrations increase the energy by several orders of magnitude,

- Power - the above properties of laser beams ensure that the energy of the highest density is focused on a minimal area of material. This allows you to destroy or burn through any material in a microscopically small area.

Any laser device consists of the following components:

- energy source;

- working body that produces energy;

- an optical amplifier, a fiber-optic laser, a system of mirrors that amplify the radiation of the working element.

The laser beam produces precise heating and melting of the material, and after prolonged exposure, it evaporates. As a result, the seam comes out with an uneven edge, evaporating material is deposited on the optics, which reduces its service life.

To obtain smooth thin seams and remove vapors, the technique of blowing melt products from the laser impact zone with inert gases or compressed air is used.

Factory laser models equipped with high-grade materials can provide good indentation rates. But for household use they are too expensive.

Models made at home are capable of cutting into metal to a depth of 1-3 cm. This is enough to make, for example, parts for decorating gates or fences.

Laser cutting of metal

Depending on the technology used, there are 3 types of cutters:

- Solid state. Compact and easy to use. The active element is a semiconductor crystal. Low-power models have quite affordable prices.

- Fiber. Glass fiber is used as the radiation and pumping element. The advantages of fiber laser cutters are high efficiency (up to 40%), long service life and compactness. Since little heat is generated during operation, there is no need to install a cooling system. It is possible to produce modular designs that allow you to combine the power of several heads. The radiation is transmitted via flexible optical fiber. The performance of such models is higher than solid-state ones, but their cost is higher.

- Gas. These are inexpensive but powerful emitters based on the use of the chemical properties of gas (nitrogen, carbon dioxide, helium). With their help you can weld and cut glass, rubber, polymers and metals with a very high level of thermal conductivity.

Homemade household laser

To carry out repair work and manufacture metal products at home, do-it-yourself laser cutting of metal is often required. Therefore, home craftsmen have mastered manufacturing and successfully use hand-held laser devices.

In terms of manufacturing cost, a solid-state laser is more suitable for household needs.

The power of a homemade device, of course, cannot even be compared with production devices, but it is quite suitable for use for domestic purposes.

How to assemble a laser using inexpensive parts and unnecessary items.

To make a simple device you will need:

- laser pointer;

- battery-powered flashlight;

- CD/DVD-RW writer (an old and faulty one will do);

- soldering iron, screwdrivers.

How to make a handheld laser engraver

Laser cutter manufacturing process

- You need to remove the red diode from the computer disk drive, which burns the disk when recording. Please note that the drive must be a write drive.

After dismantling the upper fasteners, remove the carriage with the laser. To do this, carefully remove the connectors and screws.

To remove the diode, you need to unsolder the diode mountings and remove it. This must be done extremely carefully. The diode is very sensitive and can be easily damaged by dropping it or shaking it sharply.

- The diode contained in it is removed from the laser pointer, and the red diode from the disk drive is inserted in its place. The pointer body is disassembled into two halves. The old diode is shaken out by picking it up with the tip of a knife. Instead, a red diode is placed and secured with glue.

- It is easier and more convenient to use a flashlight as a body for a laser cutter. The upper fragment of the pointer with a new diode is inserted into it. The glass of the flashlight, which is an obstacle to the directed laser beam, and parts of the pointer must be removed.

Laser pointer

When connecting the diode to battery power, it is important to strictly observe the polarity.

- At the last stage, they check how securely all the laser elements are fixed, the wires are connected correctly, the polarity is observed and the laser is level.

The laser cutter is ready. Due to its low power, it cannot be used when working with metal. But if you need a device that cuts paper, plastic, polyethylene and other similar materials, then this cutter is quite suitable.

How to increase laser power for metal cutting

You can make a more powerful laser for cutting metal with your own hands by equipping it with a driver assembled from several parts. The board provides the cutter with the required power.

The following parts and devices will be needed:

- CD/DVD-RW writer (an old or faulty one will do), with a writing speed of more than 16x;

- 3.6 volt batteries – 3 pcs.;

- 100 pF and 100 mF capacitors;

- resistance 2-5 Ohm;

- collimator (instead of a laser pointer);

- steel LED lamp;

- soldering iron and wires.

You cannot connect a current source to the diode directly, otherwise it will burn out. The diode draws power from current, not voltage.

Laser collimator

The beams are focused into a thin beam using a collimator. It is used instead of a laser pointer.

Sold at an electrical goods store. This part has a socket where the laser diode is mounted.

The assembly of the laser cutter is the same as the model described above

To remove static from the diode, aluminum wire is wound around it. Antistatic bracelets can be used for the same purpose.

Assembly Tips

To check the operation of the driver, use a multimeter to measure the current supplied to the diode. To do this, connect a non-working (or second) diode to the device. For most homemade devices, a current of 300-350 mA is sufficient.

If you need a more powerful laser, the indicator can be increased, but not more than 500 mA.

It is better to use an LED flashlight as a homemade housing. It is compact and convenient to use. To prevent the lenses from getting dirty, the device is stored in a special case.

Important! A laser cutter is a kind of weapon, so it should not be pointed at people, animals, or given to children. Carrying it in your pocket is not recommended.

It should be noted that do-it-yourself laser cutting of thick workpieces is impossible, but it can cope with everyday tasks.

on topic: How to assemble a Laser with your own hands

DIY laser cutter for cutting plywood, wood, metal: assembly tips

The possibility of making something useful out of unused or worn-out equipment attracts many home craftsmen.

One such useful device is a laser cutter.

Having such a device at your disposal (some even make it from an ordinary laser pointer), you can decorate products from various materials.

With a homemade laser cutter you can cut thin wooden parts or engrave glass

What materials and mechanisms will be required

To make a simple laser cutter with your own hands, you will need the following materials and technical devices:

- laser pointer;

- a regular flashlight equipped with rechargeable batteries;

- an old burner drive (CD/DVD-RW) equipped with a laser drive (it is not at all necessary that such a drive be in working condition);

- soldering iron;

- set of locksmith tools.

The higher the write speed of the drive, the more powerful the laser cutter will be.

Thus, you can make a simple laser cutting device using materials that are easy to find in your home workshop or garage.

Paper Cutting Tools | scruboo.ru

A paper cutter is a device for cutting paper quickly and evenly. Very useful when designing scrap pages and postcards. The cutter allows you to cut a sheet of paper so smoothly that no scissors can cut it.

According to the method of impact on the knife, cutters are divided into mechanical (manual) and electric. In turn, hand cutters come in roller, saber and guillotine types.

A roller cutter (also known as a disk cutter or trimmer) is a rectangular base (work table) along which the cutting mechanism moves along a guide. It, in turn, consists of a sharpened metal disk enclosed in a protective casing. When cutting, the paper ends up between the roller cutter blade and the counter knife (a hard metal plate attached to the end of the platform on the side where the cutter moves). This cutter is ideal for working with a small amount of paper - up to 10 sheets, it comes in different sizes, the most common are 22.5 x 12.5 cm; 31 x 31 cm; 20 x 46 cm. It takes up little space and has a valuable quality - the ability to cut an edge less than a millimeter wide, which allows you to work with maximum precision. In roller cutters, the knives are not subject to secondary sharpening, although they are called self-sharpening. They just need to be changed after a certain time.

The saber cutter is called because of the knife, which is similar to a saber.

The reciprocating cutter is the most powerful and is used for working with large volumes of paper, but their accuracy remains within 0.1 mm. Reciprocating cutters have a slightly different operating principle. The sharpened knife of the cutter is fixed at one end (to avoid injury it is covered with a protective casing), and at the other it has a handle. By lowering it, they cut the paper. The knife can be sharpened in a reciprocating cutter, although this procedure is not as simple as it seems at first glance. In addition, using a reciprocating cutter is much more difficult than using a roller cutter. To get the perfect result, you have to try. The guillotine cutter is used for processing large print runs and is perfect for large printing houses. This cutter can be manual, semi-automatic or automatic. Its working mechanism (a sharpened heavy cutter knife) is located on a massive table and is driven by a lever or electric drive. The blade moves not only from top to bottom, but also obliquely along the cutting line and is capable of “processing” impressive stacks of sheets up to 8 cm. At the same time, the accuracy reaches fractions of a millimeter. When the cutter knife becomes dull, it is removed and sharpened, and after several sharpenings it is replaced.

A breadboard knife is used for cutting paper, sharpening pencils, and is also necessary for cutting out small parts and complex shapes. It is a thin, replaceable blade similar to a feather with a protective cap. When working with such a knife, you must have a breadboard mat (cardboard, hardboard or plywood) so as not to damage the table on which you are working.

Roller breadboard cutters allow you to quickly and effortlessly cut paper, as well as make a variety of shaped cuts with special attachments.

The circular knife is used for cutting circles with a diameter of 10 mm to 150 mm. Ideal for making cards and round parts for scrapbook pages. The knife is an axis with a needle and a movable leg on which a blade is mounted, by means of rotation of which a circle is cut. There is also a scale on the movable leg for selecting the diameter of the circle to be cut. It is necessary to work with a compass knife on a breadboard mat. Make sure all screws on the compass are tight before cutting.

A shape cutter can easily cut out any shape using a special stencil; it is indispensable when creating decorative elements for pages and postcards. Some models of shape cutters can be used without a stencil. When working with such a cutter, you must have a prototype mat so as not to damage the table on which you are working and be sure to check the serviceability of the blade and, if necessary, adjust it in accordance with the density of the selected material.

I hope the review will be useful. We wish everyone a good mood!

www.scraboo.ru

Paper cutter - rating of the best models, how to use it and make it yourself?

Currently, the process of simultaneously cutting a large number of sheets is no longer something unrealistic. This is possible thanks to a device such as a paper cutter. Today there are a variety of designs and models on the market, so it is important to choose the right option.

Types of paper cutters

Devices are divided according to many characteristics. Depending on the design, paper cutters can be:

- roller;

- saber;

- curly;

- guillotine.

According to the drive method, the cutter is:

- mechanical

- a manual paper cutter is activated by pressing the lever; - electric

- operation is carried out by pressing a button.

According to the area of use, a paper cutter can be:

- office;

- specialized;

- professional.

Guillotine paper cutter

The most powerful type of product can cut a stack of paper up to 800 sheets. On sale you can find a manual, semi-automatic or automatic guillotine paper cutter.

The structure is activated using a power lever, but there is no need to apply a lot of physical force.

Due to the high cost, it is advisable to use such options on an industrial scale. The advantages include:

- obtaining an ideal cutting line;

- you can sharpen the blade;

- the ability to simultaneously cut a large stack of sheets;

- the cutting mechanism is protected;

- The most durable paper cutter ever.

Among the disadvantages are:

- inability to create decorative cuts;

- Do not make holes in the center of the sheet;

- high cost.

Roller paper cutter

A type of cutting machine that easily cuts up to 15 sheets at once. You can find mechanical or electrical models on the market. The device has a wooden base with markings and a screwed ruler.

There is a roller blade on one side. Place paper under the bar and clamp it. The knife has the ability to move in two directions.

Due to the large size of the working surface, such devices are often used in printing companies and photo salons.

Disc paper cutters allow you to accurately and accurately cut edges even less than 1 mm wide. In addition, it is possible to carefully control the cutting line. Among the advantages are:

- you can observe the cutting line;

- there are replaceable knives;

- you can cut a piece of sheet from 0.5 mm.

The disadvantages include:

- Over time, an error of up to 2 mm appears;

- you can't make a slot.

Reciprocating paper cutter

A powerful type of device that can cut up to 50 sheets.

A desktop paper cutter is equipped with a sharpened knife, which is fixed on one side, and on the other has a plastic handle that a person holds on to.

Their low cost makes them accessible even to small firms. In order for the cutting line to be as accurate as possible, it is important to always keep the knives sharp. Among the advantages of this option are:

- you can cut cardboard up to 4 mm thick;

- pressing sheets with a fixing device;

- with proper use, the knife remains sharp for a long time;

- some models have backlighting;

- presence of markings on the surface of the base.

The disadvantages include:

- when cutting a large stack of sheets, an error of up to 2 mm is possible;

- difficulty in sharpening blades;

- rapid dulling of knives when cutting thick paper;

- presence of noise during operation.

Homemade paper cutting machine

Today, almost every home has a printer, laser or inkjet.

Sometimes you have to print photos, cards, etc. on larger paper.

Afterwards you will need to trim the paper exactly to the required size.

To do this, you don’t have to buy a machine; you can make it yourself.

I think it won’t be difficult to make a simple machine for cutting A4 into A5 and A6 formats from photographs.

For this we need:

- Chipboard 20*180*540.

- PVC corner 20*20.

The main thing is to accurately install the guides. Gaskets 4 sheets of paper thick are placed under their ends.

Using this device, you can easily and evenly cut the desired size of paper.

Author: valeriy

P O P U L A R N O E:

- Decoupage. A convenient way to glue napkins

Salt method for gluing napkins

Hello, dear readers!

Happy New Year 2022! I wish that he becomes a good boy for you, pleases you with his gifts and pleases you with pleasant surprises