A couple of weeks ago I installed one of my wind generators to help with solar panels. I put the blades on it that I found, two blades from 160-gauge pipe and two from galvanized sheet metal. The propeller seemed to work, but I wanted to make a normal propeller, one that would be fast and have a good starting torque. Below in the picture is a windmill with prefabricated blades, the quality is of course disgusting, but I think it’s clear what is shown.

Pipes of 110.160 mm with a speed of 5-6 did not want to show a good starting torque in the program, and pipes with a larger diameter are difficult to find. A good result in the program for calculating blades made of PVC pipes was given by pipes of 250.315 mm, and the starting torque is high, and the speed with KIEV.

Then I decided to try to make blades from tin, or more precisely from scraps of professional flooring that remained after sheathing the house with professional flooring. Previously, in the program, I adjusted the screw from the 315th pipe for my generator. The three-blade propeller turned out to have a diameter of 1.5 m, high speed with a high KIEV of 5-7, the starting torque at 5 m/s is 0.25 Nm. Below are screenshots from the blade calculation program.

Here is the data for cutting the screw - all dimensions in millimeters, which I then used to make the blades.

From the scraps of professional flooring, I chose three suitable small pieces and cut them to 75 cm with a grinder. Next, using a hammer, I began to straighten the profile into something like a smooth sheet. I immediately folded the back edge with a 1cm grip.

Next, I outlined the dimensions from the program on the workpiece and drew a front line along which I would cut the blade. I added 1cm to the dimensions because I will also bend the front part for rigidity. Below in the photo you can see the line along which I will bend the tin with pliers. The thickness of the tin is 0.6mm, but I cut it with ordinary scissors, not a grinder, it’s smoother and easier.

The process of bending the edges of the blade. The hem is done using pliers and then tapping with a hammer.

The process of making the remaining blades is the same, one blade took about twenty minutes of work and the result was these still flat blades.

This is what the blades look like from the reverse side.

Next, by longitudinally tapping with a hammer, I gave the blades the shape of grooves approximately like those of the 315th pipe. To roughly guess, I drew a circle with a diameter of 320 mm on the floor and guided myself by it. I exposed the root part of the blades to 3 cm, and folded the blades together and drilled holes along the zero line. I drilled holes with a diameter of 6mm.

View from the back.

So, spending about an hour and a half, I made the blades for the wind generator. The blades turned out to be flimsy, of course, but as practice has shown, such blades can withstand winds of up to 15 m/s. Next, I cut out a hub from plywood and assembled the finished screw.

Below is a photo of this propeller already on the wind generator.

After installation on the wind generator, the new propeller immediately showed its good side. There was a wind outside of about 3-6 m/s and the propeller was spinning well with a noticeably higher speed. It instantly responded to changes in wind speed and spun without stopping. Before it, a prefabricated four-blade propeller first melted, but somehow it did not gain high speeds. Then I removed two pieces of tin blades and two blades from the 150th pipe remained there. I connected the windings of the generator with a triangle and in this form the windmill worked with a two-bladed propeller, but the propeller periodically stopped and then had difficulty starting. The charging current was unstable, but in today's wind gusts it reached 4A.

With the new three-bladed propeller, the charging is almost constant, 0.5-1A is visible on the ammeter constantly with an increase to 2A. We'll see how it will be in stronger winds, but it's not bad. Because of the speed, charging does not stop and the propeller starts easily, which is what I wanted to do. I think the screw is strong enough, but time will tell. I haven’t come across screws for windmills made of tin on the Internet, and of course, in terms of strength, they cannot be compared even with PVC pipes, but this is also a solution when it is problematic to get large-diameter sewer pipes.

Many owners are trying to find a highlight for the exterior of their home, but there are not many such devices. A weather vane is ideal for this. It simultaneously performs both practical and aesthetic functions.

Features of a weather vane with a propeller

This device can be of different shapes, most often the weather vane has the shape of a domestic or wild animal, an angel, a fairy-tale hero, or an airplane.

A weather vane is not only a functional device, but also a decoration for the roof of a house.

Selecting material for making a weather vane

The main criterion when choosing material for a weather vane should be the ultimate purpose of its manufacture. But despite this, it is recommended to choose the material that will make the structure a decoration of your home for a long time. A weather vane can be made from almost any material, but each of them requires different tools and equipment.

For more information about what you can make your own weather vane from, read our article - Where the wind blows from: how to make a weather vane with your own hands.

Wood weather vane

A fairly light and easy-to-work building material that does not require specific tools and skills. High quality raw materials are suitable for a weather vane. Before use, it is recommended to impregnate the wood with mixtures to protect it from dampness and harmful insects. However, such a product will not last long.

Option 1. Simple weather vane

This product can be placed in the garden or local area just for decoration. However, it is also useful for schoolchildren, who are asked to keep a “weather diary” and determine the prevailing wind direction every day.

To make it, you will need a stick as a support, and a small piece of thick wire on which you will need to place the weather vane. The simplest option is to pierce a bottle with wire, bend a loop at the top, add a large plastic bead at the bottom, and fix the resulting structure in the center of the stick. Before installing the wire, you can paint the bottle in bright colors using acrylic paint. A cheaper option is to use multi-colored electrical tape, which you always have on hand at home.

Basic elements of a weather vane

Regardless of what shape your weather vane will be, it must contain certain elements, the main ones being an axis and a flag with a counterweight.

Vane body and axis

The body serves as a support for the entire structure. Both steel and brass pipes with a diameter of 1 inch are suitable for its manufacture. The body has a strictly vertical axis - a rod, usually made of steel reinforcement.

The main function of the support rod is to hold the windmill. The diameter of the reinforcement is about 9 mm, this is enough to withstand strong winds and any other mechanical load that will act on the weather vane.

The weather vane body is the support of the entire structure

Flag with counterweight (wind vane)

The main part of the device located on the vertical axis. The flag shows which direction the wind is blowing. The counterweight serves to balance the flag and is located on the opposite side. The main difficulty in the manufacture of this element is that the flag and the counterweight must be located evenly on both sides of the axis, that is, have the same mass.

Of the entire structure, it is the weather vane that is of artistic value. An experienced craftsman is able to make a part of any shape without disturbing the balance between the flag and the counterweight.

When making a weather vane, it is important to maintain an even distribution of mass on both sides of the axis

Protective cap

The protective cap has the shape of a circle or a cone and is located on the axis of the weather vane, most often directly above the body. Its main function is to protect the housing and bearings from moisture and dirt.

Rose of Wind

A cardinal direction indicator consisting of two rods crossed at an angle of 90°. As a rule, the rods are attached to the top of the lid in a stationary state. At the ends of the pointer, letters are installed to indicate the cardinal directions. To fix the element in the correct position, you need to use a compass.

To set the cardinal direction indicators in the correct direction, you need to use a compass

Bearings

They are located inside the body and ensure free movement of the supporting rod under gusts of wind. The internal diameter of the parts is 9 mm.

Fasteners

The choice of fasteners depends on the material used and the method of fastening. These can be corners, overlays, bolts, rivets.

Propeller

It helps determine wind speed. You can make the propeller yourself from plastic and wood or use ready-made parts.

It is the airplane with the propeller that looks most organic, since this detail is also present in the original design. And it’s much easier to model this shape than others.

The plane is ideal for making a weather vane with a propeller

What is a weather vane and its types?

The weather vane is an antique decorative element and also covers the chimney pipe, protecting it from the penetration of precipitation: rain and snow. A weather vane attached to the chimney will give the roof an aesthetically pleasing and complete appearance. It is a metal structure consisting of a flag and a counterweight.

A weather vane mounted on the chimney is the finishing touch. Dome on the chimney - protection, weather vane - decor

The principle of operation is simple: the counterweight is directed in the direction from which wind currents are blowing, and the flag indicates their direction. The tradition of installing a weather vane came from Europe. The flag is now a real decorative element. It can be made in the form of a figurine: a bird, an animal, a man. In Rus', the most popular figurine was the one depicting a rooster, since a popular legend said that its voice was capable of driving away demons. Nowadays, the image of a ship, which is considered a symbol of a happy and successful life, is relevant. The lion, in turn, is a symbol of enormous vitality, nobility, justice, as well as the desire to move forward.

Weathervane-arrow - you are probably already familiar with it

Main types of weather vanes:

- indicating the direction of the wind. It is widely used in meteorology. Despite the availability of many modern devices, weather vanes are still in demand. They occupy a special place in coastal cities, since the functioning of ports directly depends on the direction of the wind. The response of the weather vane is noticeable even at the slightest appearance of wind flow and is detected even when other devices are still powerless;

- Wilda. This is a more modern weather vane model, capable of determining not only the direction, but also the strength of the wind. This model has a plate mounted vertically. The angle of inclination shows strength.

The chimney vane has a simple design and can be made with your own hands.

Drawing of an airplane weather vane with a propeller

A weather vane is usually located on the roof, so high aesthetic demands are placed on it—its appearance will judge not only the taste of the owner of the house, but also his wealth. Therefore, it is very important to design the structure correctly, while showing maximum imagination and creativity. The drawing of the future model should be as detailed and accurate as possible.

The drawing of the future aircraft model should be as detailed as possible and with exact dimensions

Types and material for manufacturing

To ensure appropriate quality for the device, the following materials are used for its manufacture:

Copper. This metal allows the weather vane to serve for many years, remaining in an unchanged condition. When installing a copper device on the roof, use fastening materials made of the same metal, because copper can react chemically with others. If you use elements other than copper for fastening, then in a short time the appearance of the weather vane will be ruined.

Galvanized iron and steel

The material used for manufacturing allows the devices to be painted, which is important for home design. In addition, they have a high level of strength and are no less reliable than copper ones.

Variety of types and shapes

Based on the shape of the weather vane, there are:

- Standard. It is a mini-house that rises above the chimney pipe. They have various design solutions.

- With rounded lids. This type of weather vane is more typical for Europe, but is also popular in Russia. Given their design, which has increased aerodynamic properties, condensation from precipitation does not accumulate under the cover.

- With multi-slope lid. They imagine a mini-roof with two slopes on each side. This shape provides the weather vane with better protection from precipitation in the form of snow. Additionally, weather vanes are placed on such a weather vane, which can have the shape of various objects or animals.

- With opening lid. Despite the fact that the weather vane is designed to remove air masses, this design can also increase the traction force.

IMPORTANT!

One of the most convenient designs of a weather vane on a chimney pipe is a cap with an opening lid. Ease of use is determined by the ease of cleaning the chimney pipe, because there is no need to remove the weather vane.

Step-by-step instructions for making an airplane weather vane

This device will become the hallmark of the house only if the element is properly made and installed.

Metal weather vane

It is performed in the following sequence:

- Cut a pipe 120 mm long. Make small holes in it for fastening to the support with rivets or bolts. The holes must first be tapped.

- Insert bearings from each end into the pipe, securing with welding. Additionally, the bearings can be fixed by heating the pipe into which the bearing must be inserted. After the pipe has cooled, the bearings will sit quite firmly in it. Fill the pipe itself with grease.

Bearings help the weather vane to easily rotate around its axis

It is very easy to cut steel sheets with special metal scissors

Weather vane made from plastic bottles

You can make an airplane weather vane from plastic bottles. To do this you need:

- Collect empty containers and wash them thoroughly. For a weather vane in the shape of an airplane, 4 bottles are enough. Cut off the top part of two bottles with the cork halfway. As a result, you should have 2 cut tops with cork and 4 bottoms, the height of which is 5 cm.

Making your own windmill from PET bottles

Making a windmill with your own hands from a PET bottle will not take much time. The most difficult part here will be the process of cutting out the propeller. For beauty, it can be made from a container of a different color. For example, the body will be transparent and the propeller will be brown. But first things first:

- To make a weather vane you will need 2 bottles.

Color and capacity can be taken according to preference. It is necessary to have 1 plug for attaching the propeller. Advice! A high-mounted body made of a transparent bottle will be difficult to see, especially if it has a blue tint to match the color of the sky. It is optimal to use colored containers in dark tones. - The bottom of one bottle is cut off and, upside down, as in the photo, markings are made with a marker. There should be 5 blades along the edges of the bottom.

- The plastic closer to the bottom is thicker and cutting it with scissors will be problematic. It is better to use a hand jigsaw or a hacksaw blade for metal. From a brown bottle with a capacity of 2.5 liters you can cut a screw like this, as shown in the photo.

- A hole is burned in the center of the propeller with a hot nail. It can be drilled out with a thin drill or the sharp end of scissors.

- An axle is made from a 5 cm piece of wire 2 mm thick. It is heated red-hot over a fire and inserted into the center of the cork. The wire should melt into the plastic plug.

- To rotate the windmill itself, you need to make another axis with your own hands, only in the neck of the bottle. It is made in the same way as in a cork, only it is advisable to take a steel wire and 20–30 cm long. You should get a knot, as in the photo.

- A bottle is placed on a common axis of rotation through a hole in the neck. The rod is wrapped with electrical tape on both sides of the neck. The limiter will prevent the bottle from lowering or raising along the axis.

- The cork with the fused wire is screwed onto the thread of the bottle, the propeller is put on using the same method, and the limiter is wound. For reliability, the limiters can be pressed with several turns of copper wire.

Your handmade windmill is ready. All that remains is to attach it to the mast and install it as high as possible.

This video shows a musical weather vane:

DIY weather vane: components

For reference. A decorative element for home decoration can have a different shape: a weather vane on the roof can be found with images of animals, angels, fairy-tale characters, etc. There are accessories on the roof in the form of a family coat of arms or an entire composition depicting some action when exposed to wind.

Main design details:

- the central vertical axis of mounting on the roof, rotation is performed around it;

- weather vane - an element indicating where the wind is blowing from; it is fixed on the main axis;

- pins crossed in the horizontal plane with a designation on them in letters representing the sides of the horizon;

- a metal plate in a vertical hanging position (counterweight), changes its angle under the influence of wind.

For a weather vane to become a real calling card of the house and its owner, the element must be made and installed correctly.

Empty plastic bottles: use as intended

Four empty plastic containers can become material for making a simple weather vane. You will also need a cutting knife, a metal rod, and a pole used as the axis of the structure. We start making a weather vane from plastic bottles... by collecting empty containers.

Bottles are cut differently. For two of them, the upper part (with the stopper) is cut off for further use, almost half the length of the container. The bottoms are also not thrown away, but are used together with two others, cut off from the remaining two bottles. The result is two cut “tops” and four bottoms the height of a 200-gram glass.

On each of the four containers, using a sharp knife at an angle of about 45 degrees at the cut line, make one cut along the oblique in the form of a hangnail. This is a kind of fastener to which the weather vane parts will cling with the same burr. With the upper parts of the bottles, prepared in advance, proceed as follows:

- the plug of one of them is unscrewed;

- in the center of it, using a knife or a hot rod, a hole is made - a groove for the axis on which the entire structure will be supported;

- a plug with a hole is screwed onto the neck.

- the other “top” remains without a lid.

The weather vane is assembled in the following sequence. First, the two tops are joined using cut surfaces with pre-cut grooves. Like a nesting doll, they are connected to each other by easily screwing one into the other. They attach the resulting “body” with oblique cuts at the junction of the bottom. They should be located around the volumetric body in one direction.

A rod, branch, metal rod - anything that can be used as an axis - is threaded through the bottom hole of the bottle. The top limiter will be the bottle cap, into the hole of which the axis of the weather vane will fit tightly. The structure is ready. Can be installed in a convenient place. When the wind blows, the light plastic blades will begin to rotate.

How to make an electronic repeller

- With the slightest knowledge of electronics, assembling the device is not at all difficult. Large financial costs will not be required either. You need to purchase a microcircuit and transistors. To regulate the frequency of sound, it will be necessary to create an additional unit consisting of resistors, transistors and diodes designed for protection in case of polarity reversal.

- After assembling the device, you need to check the resistance of the resistors so that the load is applied to them evenly; additional installation of a piezoceramic emitter will be required.

- Power supply for the repeller is a standard crown, voltage -9 V.

- The LED flashlight is built into the front of the housing.

- To increase the power, it is advisable to install 8 batteries (AAA standard), capacity 300 mAh, under the crown.

- The essence of the electronic device is the activation of a high-frequency pulse generator when a dog approaches. The frequency is not perceptible to humans, but animals hear the noise of the generator very well.

Do not experiment with the device on your pets; if you point the repeller at them, you may lose their trust in the future. Set the frequency recommended by the manufacturer; if it is exceeded, the device will quickly fail. Usually the device is designed for 30 meters, which will not allow the animal to invade your territory

When choosing a finished device, pay attention to the cost, ease of design, quality of all components, manufacturer’s brand, and production technology. Please note that cheap devices may be ineffective, unreliable, and may not meet the parameters specified in the documentation

Choose an acceptable type of device in advance; if you carry it in your pocket, it is better to buy a portable model. If you need to install it on a tree or wall, choose a stationary device. Cobra is considered a new and high-quality model with 4 operating modes; it can be used as a security system

A small pocket device - Osa, costs only 1200-1500 rubles, is effective and convenient to carry in your pocket. The ultrasonic device with a power of 130 dB is distinguished by high volume. At a distance of 1 meter for a dog, this is the noise of a jet plane, the effect on the animal is simply deafening, thereby you can put it in an aggressive state, you will only make things worse for yourself in particular. Do not rush to use the device if the dog is calm and does not at all seek to harm you. A distance of 4-15 meters is considered large for the repeller to work effectively; it may simply not have an effect on the animal and lose its power at a distance. Consider the range of the device when purchasing or designing a model yourself. Do not panic when an animal approaches, do not make sudden movements. Keep your finger on the button; when attacking, it is better to let the predator get closer, the noise will be deafening, and the shorter the distance, the more effective the device will be. Do not play with the repeller, do not turn it on unnecessarily, for example, pointing it at a quiet, innocent dog. 13.Do not let children play with the device; it is better to teach them how to handle it correctly. Don’t be a provocateur by turning your pet against you; with the device turned on, you can provoke aggression, but why would you want to do that?

Chimney Decoration

To enhance the efficiency of the chimney, as well as to protect it from precipitation and debris, you can design and install a weather vane deflector with your own hands. The height of the structure should be in a ratio of 1.7 to the internal cross-section of the chimney. The width of the deflector is 1.3 times the diameter of the smoke channel. Galvanized iron sheets, copper or stainless steel are suitable for manufacturing.

First, on thick cardboard, a sketch is made in expanded form of all the parts: cap, cylinder, diffuser. Using the templates made, these parts are cut out on metal. The entire structure is assembled together, the individual elements are bolted together, either welded or fixed with rivets.

The finished product is installed at the end of the smoke channel using a ring with a bearing assembly so that the housing rotates together with the deflector visor. A weather vane on the chimney pipe will not only provide a constant flow of fresh air into the room and effectively remove flue gases, but will also become a real decoration of the roof.

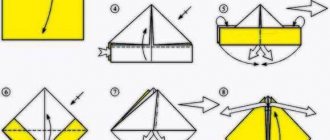

Option 2. Pinwheel

A wonderful children's toy that can serve as a decoration for the local area. It is cut from one plastic bottle, from which the bottom is first cut off, and then the entire side surface is cut into 3-7 strips. This is how the turntable blades are made. They must be folded perpendicular to the neck and processed over a candle flame to melt the sharp cuts. Slightly softened plastic can be easily turned at an angle of 45 degrees or the surface slightly bent to form fan blades. A hole is made in the lid with a nail, then it is necessary to enlarge it slightly, but so that the diameter of the hole does not exceed the size of the nail head. After this, a stick is dug in, and a nail is nailed to it, onto which a large flat bead, a pinwheel, and another bead have previously been placed. Instead of beads, you can use stronger flat metal washers. In this case, the product will rotate well and will not fly off the nail.

You can improve this option and place several of these turntables on one long bolt. Then the sequence is as follows: a washer, a pinwheel, a washer, a nut fixed in the middle, then again a washer, a second pinwheel, a washer and a plug for the bolt.

Airplane on the roof: an original weather vane in our own design

Wind direction and speed can be determined in different ways. For example, by making an airplane weather vane with your own hands. A mock-up of an aircraft with a length of 500 mm and a wingspan of 300 mm is preliminarily designed and manufactured.

Please note. The material for the aircraft should be light: foam plastic, plywood, etc. This will allow the aircraft to rotate freely on the axis of the rod.

A weather vane with a pole is attached to areas unprotected from the wind. Or installed on the roof. Two supports are taken or made with a hole in the middle of 5 mm: from wood, wire, metal plates, etc. The brackets are placed among themselves so that there is a gap of 20 cm between them. A rod is passed through the holes drilled in the support-brackets. It can be a thin tube, iron or wooden rod.

A nail (piece of wire) is attached to the top point of the rod. An airplane is strung on it - a toy model. The plane is at a slight angle to the axis. When wind occurs, the flow blows onto the wing, the aircraft with the rod rises to a certain height, which will be identical to the wind speed. If desired, you can install a graduated scale. Then, when the device rises up, you can read the approximate wind speed.

To decorate your yard with an original weather vane, you need to be smart, use your imagination, put your hands to work, and then it will become the exclusive calling card of your yard.