Ways to solve the problem

Although a tool such as a screwdriver is the most popular, not every home craftsman uses it every day. Every day the battery is subject to spontaneous discharge, as a result of which the internal structure of the product is destroyed.

After the battery does not last for several minutes, the question arises, what to do with the screwdriver now? You can buy a new battery, but first you need to find it, because you can only find the exact design of the power element from official dealers. The second option is to throw away the screwdriver and buy a new one, the cost of which is at least 2-3 thousand rubles (this is an average quality product). The third option is the simplest, but at the same time it requires effort - to convert the product to be powered by alternating voltage.

The advantages of the latter option are the following factors:

- There is no need to constantly recharge the battery, which is very annoying during the work process;

- Now the screwdriver can be stored as long as you like, without thinking that the battery spontaneously discharges every day;

- Constant torque, which will provide voltage from the mains.

Among all the advantages, there will be only one drawback, which is due to the need to connect the device to an outlet, so the product must be connected to the electrical network during operation.

A beautiful top made from a large T-shirt, without the use of threads or needles

You will need:

- t-shirt

- scissors

- chalk.

1. Mark with chalk on the front of the shirt what is drawn with red lines in the image.

2. Cut along the lines.

3. Mark with chalk on the back of the shirt the other lines that are drawn in red in the image.

4. Cut along the lines.

5. On the back, cut the middle section halfway lengthwise.

The front of the T-shirt after cutting.

The back of the T-shirt after cutting.

6. On the front of the T-shirt, tie two stripes into a knot, then move them back and tie them to the back stripes.

*If necessary, you can cut off excess parts of the fabric or tie them in a bow.

Required materials and tools

For most, the third option may seem difficult, because it is much easier to buy a new device and use it for several more years. In fact, the old screwdriver will last even longer, but for this it is necessary to restore it. This is quite simple to do, and you will need the following tools and materials:

- A charger that previously played an important role in charging the battery.

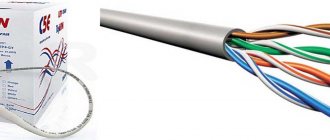

- Multicore electrical cable.

- A battery from a screwdriver that has become unusable.

Tools you will need are a soldering iron, acid, solder and insulating tape.

All these details will allow you to transform the screwdriver so that it can be connected to a 220 Volt network.

Fantasies on the theme of shortened length

Products with shortened lengths very accurately fall into modern trends. This means that, armed with scissors, you can turn any thing into a fashionable novelty. Moreover, you shouldn’t worry about a slightly sloppy edge - this will only give the clothes some flair. You can start such experiments with a loose or men's T-shirt. The action plan is simple - cutting the hem and rolling up the sleeves.

A few simple movements with scissors and a simple T-shirt can be turned into a trendy cropped top. A great addition to stylish summer looks!

The shortened length can be easily complemented with long ties (which can also be obtained from the original T-shirt).

It's also easy to create fashionable crop tops from old T-shirts and T-shirts.

Your scissors can also touch jeans with a loose fit - such products are now very popular in a shortened length with a raw hem.

Where to start work

- To convert a screwdriver to be powered from a 220 V electrical network, first of all, you will need to solder an electric wire to the contacts of the charger. But since the wire has copper conductors, and the power supply has brass terminals, connecting them will be very difficult. But nothing is impossible in the world, so we use acid as a connector. It is necessary to treat the terminals of the charger with acid, and then solder the wire to the contacts. The connection must be of high quality, since the contact and functioning of the device itself depends on it.

- At the next stage, the old battery is rebuilt. To do this, it must be disassembled and the entire internal part removed from it. Although the manufacturer does not recommend doing this, we will need the battery design. When disassembling the battery, it is important to use protective equipment and not throw the internal contents in the trash, but rather recycle it. A weight should be placed in the battery case, which will act as a counterweight.

- After the inside of the battery has been removed, we begin the process of soldering the free contacts of the electrical cable to the battery terminals located in the inside of the case.

Important! During soldering, it is important to control the polarity, but if it is not observed, then nothing terrible will happen, only the device will function in the other direction. But with the help of a switch this situation can be easily resolved.

The electrical cable is inserted into the battery from the outside, making a special hole in the structure of the required diameter. After this, it is important to ensure that the cable is securely fixed in the battery housing structure. For this, you just need insulating tape, with which you should wrap the cable inside and outside, thereby making a lock. After this, insert the battery case into the screwdriver and use it for its intended purpose.

Updating an old item

With the help of additional parts and accessories. These are rhinestones and buttons, beads and sequins, as well as all kinds of rivets and other decorative accessories.

Yes, just replace some buttons with others, or another fastening with shiny shades.

Experiment with stripes, thermal stickers, and inserts. Cut out all the pockets from denim trousers and sew as many of them onto a youth skirt as you wish.

Wedge inserts, cutouts, and slits are the most common refacing details. For example, sew lace or pieces of knitwear into part of the sleeves of a man's shirt. Or sewing something onto the lace part of a dress.

Note!

DIY vase: step-by-step photo instructions, master class for a beautiful and unusual craft

- Paintings from buttons, panels, appliques and compositions with your own hands: how to make flowers, a butterfly, a fish or a tree craft from buttons

Flowers made of wool (85 photos) - how to felt a flower from felt or a wool brooch. Step-by-step instructions for beginners

Don't forget about prints. This is any image of a special application on fabric. You can minimize them - make inscriptions using letters or symbols (hieroglyphs) of other languages. Or draw them yourself with non-washable markers.

And again, a thing updated beyond recognition will take a place in the wardrobe of a woman or man.

Options on how to do it + (Video)

If the power supply has also become unusable, then do not be upset, since there are other options for how to power the screwdriver:

PC power supply

The power supply for the screwdriver can be provided by a PC unit, which is much easier to find than a new battery for the device. The advantage of a PC power supply is the fact that it is possible to obtain different current values at the output, which is considered very important.

The design of the PC power supply includes a cooler that provides cooling for the transformer and its component elements, so you can immediately note that this type of power supply is durable, and in the next few years you will forget about problems with a screwdriver.

Old inverter welding

You can power a screwdriver using an old inverter welding machine, but this will require some knowledge of electrical engineering theory. After all, in this case it is necessary to add a secondary coil of the transformer, which will make it possible to obtain at the output a completely suitable current for powering the electric motor of the device. Therefore, before connecting the screwdriver to the welding machine, it is necessary to measure the current and voltage at the output, which must correspond to the values of the device.

Car battery

The last option is a car battery that can be connected to a screwdriver and used in places where it is impossible to get 220 Volt power. The disadvantage of such a device is that you won’t be able to work with a screwdriver for a long time, since the car’s power source quickly discharges. Therefore, if the standard UPS of a screwdriver refuses to function, which happens very often, then there is no need to rush to get rid of the device; just spend a few hours and the device will work even better than with a battery.

Fashionable T-shirt with a pattern cut out on an old T-shirt with your own hands

You will need:

- t-shirt

- scissors

- chalk.

1. Place the T-shirt on a flat surface and draw with chalk the pattern shown in the picture with red broken lines.

2. Carefully make cuts along the indicated lines (see image).

3. Pull the fabric a little so that the strips of fabric curl a little.

* If you want to make the same pattern on the reverse side, just repeat steps 1-3.

* If you wish, you can give the T-shirt a more rounded shape - just fold it in half lengthwise, draw one “wave” as in the picture and cut it out.

Precautionary measures

After remaking a screwdriver, it is important to adhere to the following precautions:

- Provide rest for the device every 20 minutes of operation, which will extend its service life;

- Do not operate the device at a height of more than 2 meters from the ground;

- Periodically clean the power supply from dust;

- Make sure that the electrical cable during operation is not pinched, strained or exposed to negative factors, which can lead to the creation of a short circuit current.

After the alteration, following the safety rules, the old screwdriver will last longer than the new two.

Screwdriver device

Each screwdriver, regardless of model and manufacturer, contains the following standard components:

- planetary reductor;

- DC motor;

- load limiter;

- battery;

- button for speed control.

The planetary gearbox is always located in a separate housing. It consists of a sun gear, a ring gear, satellites and a carrier. In inexpensive models, these components are made of plastic; they are less durable than metal ones in more expensive devices.

The main part is the ring gear. It has the shape of a cylinder, is rigidly fixed in the body, and has teeth along its circumference. The satellites attached to the first carrier move along them.

The sun gear is attached to a second carrier, which is rigidly mounted on the chuck shaft. It sets the satellites in motion along the ring gear. That is, the rotation speed of the carrier is lower than that of the engine. The second carrier is located higher along the axis of rotation, which means that when torque is transmitted to it, the speed of movement is further reduced.

If the gearbox is two-stage, it has two carriers, a ring gear with satellites inside. Three stages regulate the power of the tool due to an additional element in the gearbox.

The planetary gearbox in some screwdrivers is double-sided; it works as efficiently as possible and allows you to perform a wider range of tasks. Using the first speed, you can screw in or unscrew fasteners, the second - drill holes.

The load limiting device in the gearbox is activated by a spring installed in it. Its tension changes, and thus the force of the device is regulated.

A DC motor is almost always constructed the same way: it is a cylinder with magnets inside in a circle. The motor armature, made of steel, is mounted on brass supports. The motor windings are made of a material that has the properties of high magnetic permeability and is placed in the armature slots. After an equal number of turns, the winding goes to the collector plates.

Motor brushes made of graphite and metal are pressed against spring-loaded plates. Thanks to such springs, the structural elements are firmly fixed and can move along their own vertical axis. Electricity is supplied to the brushes. And the direction of rotation of the motor depends on the polarity of the current.

PC power supply

The windings in the motor may fail because they cannot withstand overloads. Therefore, it is better to ensure that the mechanism does not work at its limit; breaks in activity are needed not only by humans.

The battery is needed to supply electricity to the engine. The battery is housed in an oversized box that is attached to a screwdriver from the bottom or side and is easily detached from the case. This box contains several power elements, they are connected in series to each other.

The higher the supplied voltage parameters, the more power the screwdriver has.

The supply voltage range starts from 9V in models used in everyday life by home craftsmen, and reaches 18V in models for professional construction and repair.

The button for regulating the speed activates a mechanism based on the use of a pulse-width controller and a key made on the basis of a field-effect transistor. When the button is pressed, the variable resistor is turned on. Its resistance changes in accordance with the force on the button to control the speed: the stronger the pressure, the higher the speed of rotation of the motor and the more powerful the device works. Forward and reverse rotation is started by switching reverse.

The cordless screwdriver comes with a charger. It is necessary to recharge the battery.

How much power will the PSU need?

People who decide to learn how to make a screwdriver from the network will have to deal with the required power of the power supply.

Pulse

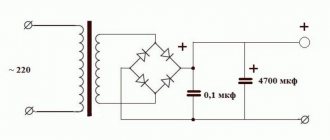

To connect the instrument to the network, a switching power supply is often used. Calculating its power is quite simple. Most often, rechargeable models operate on batteries with a voltage of 12 V. Based on this, it turns out that during operation the device consumes at least 120 watts.

It is recommended to choose a power supply with a power reserve of about 20-30%. This way the screwdriver will be able to work normally even under maximum loads.

Transformer

Since the operating voltage of most screwdrivers is 12 V, choosing a transformer power source is quite easy. You can power an electric tool using any model with a power of about 200-300 W.