Vegetable growing » Potatoes

0

1552

Article rating

Kira Stoletova

Potato tubers come in different sizes. Their sorting provides the root crop with greater shelf life. Non-mechanized potato sorting takes a lot of time and effort. Let's look at devices for sorting potatoes that make this process as fast and simple as possible.

Devices for sorting potatoes

Lattice table

When working with small volumes of crops, it is not necessary to hire special equipment or make complex structures. The most successful sorting of small quantities of potatoes is ensured by a grid table. A special drawer serves as a tabletop for it. The design is based on the passage of potatoes of the required size through a special grid, the beams of which diverge: thereby, small tubers fall before large ones.

Under the countertop there are several drawers into which the sorted root vegetables will go. A tuber of the required size falls into each tray. The table should be slightly tilted so that the potatoes themselves roll down the racks and end up in the right place.

A potato sorting table will become a convenient assistant in the household, but it has two drawbacks:

The size of the wooden box is recommended to be 1500x800x25mm. The gaps between the yards should be approximately 35 cm at the beginning and 60 cm at the end of the table.

Lattice device

When sorting small volumes of crops, there is no need to hire large-sized special equipment or come up with complex designs yourself. A table with a grid can provide sorting of potatoes in small quantities. A special drawer will serve as a tabletop for it. The sorting principle is based on the passage of tubers through a special grid.

Under the tabletop of the mini-potato sorting machine there are several boxes into which the already selected root crop will fall. A tuber of the required size falls into each tray. It is important to tilt the table a little so that the vegetables themselves roll down the racks and end up in the desired drawer.

A homemade design for sorting potatoes will be an indispensable assistant in preparing vegetables, but it has two significant drawbacks:

- Such a device does not ensure the selection of damaged tubers.

- A simple mechanism allows you to sort through a small volume of vegetables.

The overall dimensions of the wooden box must be at least 150 × 80 × 2.5 cm. The gaps between the beams should be approximately 35 cm at the beginning and 60 cm at the other end of the table.

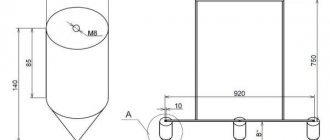

Cylindrical potato sorting

This version of a homemade sorting station is a little more complicated than the previous one. It includes: two rod cylinders soldered together, a hopper, pitched gratings, a manual drive and a frame. Grids with holes of different diameters are placed inside the cylinders.

When the cylindrical machine operates, the potatoes are sorted into three parts: small, medium and large. The first two parts are sorted sequentially in the cylinders, and the large potatoes come out. Various debris is filtered out using additional grids. The dimensions of the frame depend accordingly on the size of the cylinders.

Washing and sorting potatoes

They say it is forbidden to feed dirty beets, potatoes and other root vegetables even to piglets. But washing by hand is a tedious and rather troublesome task. As, indeed, is the non-mechanized sorting of tubers. But it’s worth acquiring two fairly simple devices, and past problems will be solved, as they say, by themselves. The potato washer is based on a “squirrel wheel” made of metal rods, inside of which “ill-fated” root crops are placed. This is a lattice drum mounted on a frame and equipped with a handle. It is lowered into a container of water. They rotate it for 30-50 seconds and the tubers are clean.

Potato washer: 1 - container with water (for washing, a drum with tubers is lowered here); 2 — hinge (2 pcs.); 3 — rods of the drum sidewalls (welded at regular intervals, 3 mm steel rod); 4 — rim (made of 5-6 mm steel rod); 5 - drum sheathing (from 600 mm sections of 3-5 mm steel rod); 6 — frame (welded structure made of steel angle 20×20 mm); 7 — handle (from a piece of metal or plastic pipe); 8 - cotter pin; 9 — V-shaped steel bracket (2 pieces, the second one without holes for a cotter pin); 10 — axle-handle (from a piece of 12-14 mm steel rod); 11 — wire loop (2 pcs.); 12 — hatch door; 13 - tubers; 14 - water tank.

Start of drum welding

The diameter of the drum and its length can be very different. As they say, it depends on who has what needs. For example, a drum can be made with a diameter of 600 and a length of 600 mm, which includes 6 buckets of potatoes. Spin a few tens of revolutions with such a device - and the job is done.

This is how tuber washing is practically done. Two rims with a diameter of 600 mm are bent from 5-6 mm wire. Next, 8 pieces of wire with a diameter of 5 mm and a length of 600 mm are prepared, according to the size of the drum.

Then a handle is made from a rod with a diameter of 12-14 mm. Bend it according to the illustration (in a bench vice). After that, already cut 8 rods of 600 mm each are welded to the handle blank. Do this as shown in the figure.

The rims (rings) are welded to the rods. From the inside of the resulting structure, the ends of the remaining 600 mm pieces of wire with a diameter of 3-5 mm are “grabbed”: as a result, the drum sheathing is obtained.

The ends or sides of the “squirrel wheel” can be made from pieces of the same wire or with solid disks, in which a number of holes can then be drilled for water circulation.

The distance between the rods is 10-15 mm (so that even the smallest potatoes do not fall through). The drum is not “sewn up” around the entire perimeter: a hatch is left for loading and unloading tubers. The last one closes with a door.

In fact, the drum can be “sheathed” with any wire mesh, even a “sieve” from sorting agricultural machines, or with a metal sheet with perforated stamping. As they say, who has what capabilities. If the drum is long, then a third rim needs to be welded in the middle.

Then a frame is made from a steel angle with a cross-section of 20x20 mm so that the drum can rotate freely there. The frame is hingedly attached to a container of water.

If the drum has a small capacity (say, 2 buckets), then it can be lifted by the other end of the frame without much effort. Well, if the capacity is large, then you will need to install an additional frame and a block through which to lift it with a special cord.

This is how it has been done since ancient times: the harvested potato crop is sorted before being stored for winter storage, and shortly before spring planting - small tubers are separated, which are fed to livestock or processed into starch.

For this, as well as for planting and harvesting, special machines and mechanisms have been developed. However, in small farms - that is, where you do not have to deal with a large number of potatoes - there is a need for simple mechanisms for sorting tubers.

If you want to save time on sorting grown potatoes, then make a simple lattice table. As a tabletop, use a low, pre-knocked wooden box measuring 1500x800x25 mm. Make its bottom from longitudinal slats with 30-40 mm intervals for the first half of the table and 70 mm for the second.

Sorting potatoes: 1 - support block; 2 - grid with two types of sorting gaps (rack, dimensions and quantity - according to location); 3 - frame; 4 - potatoes; 5 - container for sorted tubers.

Potato sorting

Place the tabletop box on support blocks at a slight angle. The main thing is that the frequent half of the bottom is higher than the rare half. Then small potatoes, falling between the cracks, will be sorted at the top of the table, and large ones at the bottom.

Minor mechanization of monotonous and tedious work, as they say, is evident. And the expenditure of time, effort and money on it is minimal. Perhaps the only drawback of such a sorting table is that diseased and damaged tubers have to be selected manually.

The next option for potato sorting is more complicated, but not much. The potato sorting machine consists of the following main parts: two paired rod cylinders, a loading hopper, pitched rod grids, a manual drive and a frame.

Potato sorting: 1 - wooden frame; 2 — rolling board for large-size potatoes; 3 — cylinder shaft; 4 - manual gate; 5 - bearing; 6 - rod cylinder of medium-fraction potatoes; 7 — rod cylinder of fine-grained potatoes; 8 — loading hopper; 9 - pitched lattice of fine-grained potatoes; 10 - pitched lattice of medium-fraction potatoes; 11 - wooden hoop; 12 - wooden rod; 13 — cross; 14 — hoop element; 15 — steel plate; 16 — cross-shaped pad; 17 — hub with a locking bolt.

The base of each cylinder is made of wooden hoops with crosspieces. The hoops consist of individual elements connected to each other and to a cross with spikes and steel plates. To prevent mechanical damage to potatoes during sorting, the crosspieces are made round in shape. In principle, the base can be made in the form of a hexagon, obtaining a hexagonal drum instead of a cylinder.

Wooden rods with a diameter of 15-16 mm and a length of 650-700 mm are attached to the inside of the hoops. They are made from durable wood. They are attached to the hoops using flexible metal tape and screws. Recesses are made in the hoops for storing the rods. If there are no rods and it is difficult to make them, instead of them you can use blocks or boards (as in the previous potato sorting design) with planed and rounded corners. The distance between the cylinder rods for small fraction potatoes is approximately 30-35 mm, and for medium fraction 40-50 mm. The inner diameter of the drum must be at least 700 mm.

The cylinders are connected with bolts. Depending on the size of the cylinders, the appropriate frame dimensions are selected. The frame can be made of wooden blocks with a cross-section of 60x60 mm or metal corners measuring 35x35x4 mm.

During operation, the cylinders are installed obliquely, at an angle of 8-10°. Potato sorting divides the tubers into three fractions: small, medium and large; small and medium potatoes are sequentially sifted through the first and second rod cylinders, respectively, and large ones are sent to the exit. The earth and small impurities are separated through the sloping grates. Sloping grates can be made longer and not so inclined for better separation of impurities. In addition, additional sorting can be carried out on the sloped grids, as in the previous potato sorting, and on the sloped grids you can make guides from boards so that the tubers roll exactly into a bag or bucket.

Dimensions of potato washing and potato sorting are approximate; Depending on the required productivity and the size of the tubers, they may vary.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

Mobile potato sorting L-701

Mobile potato sorting L-701 is a large unit that packs root crops into three parts, just like the previous design. Only such a machine is designed to work on large agricultural fields. It is capable of working both autonomously and in conjunction with a tractor in the field.

The design of such a potato sorter consists of flat, rubber-coated gratings. The holes in them are square with sides of 35 and 50 cm. The unit has its own electric drive with a power of 1.5 kW. Under favorable conditions, the machine is capable of processing 5 tons of potatoes per hour.

Unlike self-designed sorting mechanisms, the L-701 unit has quite large dimensions:

Potatoes as a raw material for food production

Requirements for the main quality indicators of potatoes upon acceptance at the enterprise must comply with current standards, taking into account the intended purpose.

Potatoes supplied for processing must have high technological advantages and have good preservation over a long period of storage.

The basic requirements for potatoes as a raw material for the production of potato products can be formulated as follows.

1. Tubers should have a high content of dry matter and starch, since the yield of products and their fat-absorbing ability depend on this. It is advisable to use potatoes containing at least 23% dry matter.

2. Varieties with non-darkening pulp are required; for this they should contain no more than 0.2-0.4% of reducing sugars (from wet weight).

3. Tubers must be smooth, regular in shape, with a minimum number and shallow eyes. Processing of such raw materials makes it possible to improve washing, reduce labor costs and waste for cleaning and post-cleaning potatoes. The peel should be thin and smooth, which reduces losses and increases production yield, but dense enough to protect the tubers from adverse external influences.

4. Potatoes must have good taste and boilability.

5. Promising varieties have good keeping quality, a slight tendency to accumulate sugars, good resynthesizing ability, and are resistant to diseases and damage.

6. It is not allowed to use frozen tubers or those affected by agricultural pests and diseases for the production of all types of potato products.

Only by using raw materials that meet industrial requirements can high-quality products with good technical and economic indicators be produced. In order to reduce the cost of potato products and obtain raw materials that meet the requirements of the industry, it is necessary to carry out commercial processing at the potato production sites and at the enterprise. It allows you to obtain products of uniform quality with the same consumer properties.

Commodity processing - sorting, sizing and packing into containers - can be carried out either with the help of separate transport devices, or with the use of potato sorting units, stationary and mobile. Schemes of the mechanized production line and sorting point are shown in Fig. 3 and 4.

Rice. 3. Diagram of a mechanized production line for commercial processing of potatoes: 1 - container tipper; 2 - bunker; 3 — roller conveyor; 4 - sorting; 5 — lock hopper; 6 — rod conveyor; 7 - sink; 8 — line for preliminary drying of tubers; 9 — conveyor; 10 — heater; 11 - dryer; 12 — roller bulkhead machine; 13 — conveyor-dispenser; 14 - scales.

Rice. 4. Sorting point KSP-20: 1 - movable bottom of the bunker; 2 — loading conveyor; 3 — separating conveyor; 4 - sorting surface; 5, 6, 7 — remote conveyors; 8, 9, 10 - container.

The sorting point allows you to select three fractions of tubers of different sizes in a batch of potatoes, separate soil and mechanical impurities, and sort tubers of non-standard quality. To sort potatoes that are sensitive to damage (immature, with uncorked skin), it is advisable to use rubber-coated sieves.

There are sorting devices that allow you to calibrate potatoes into a larger number of fractions. For example, in Germany they use sorting machines with flat sieves and boxes located one below the other, designed for calibration for six fractions. Machine productivity is 30 t/h.

Dividing a batch of potatoes into fractions at the receiving site of the enterprise allows tubers of different sizes to be sent in accordance with their intended purpose for the production of fried, frozen or dried potato products, and non-standard tubers to be used for the preparation of starch.

Back

Sorter M 616

The M 616 sorter is a large unit that sorts potatoes into 4 parts. Its design allows the machine to be moved by one person.

Potatoes are sorted as follows:

The design of potato sorting includes the following elements: feeding conveyor, heated selection table, conveyor, bag filler. The support of the machine is a frame standing on rubber wheels. Approximate amount of work per hour: 5 tons of potatoes.

Source

Buy potato sorters on the Selkhoztekhnika trading platform

In agricultural farming, sorting is a single designation for a category of machines whose main purpose is to distribute potato tubers into 3 main fractions: large, small and sowing. In some cases, definitions are replaced; potato sorting stations are also called potato sorting stations and sorting mechanisms.

There is handicraft sorting as well as machine sorting. Just like the potato sorting system, it involves special equipment that consists of gratings. Due to the progressive oscillation of the gratings, the root crops are also cleaned from dirt and inclusions. Handicraft is done by people, mechanical sorting is done with the help of special agricultural machines - potato sorting stations and potato sorting vehicles. The sorting system consists of 3 elements: - inclined conveyor - sorting cell - bulkhead table

The description of the system is also a rule of operation.

Potatoes designated for sorting purposes are thrown into the boxes of the oblique lift. The system makes it possible to fill potatoes into boxes from bags without the risk of defects in the intakes. An inclined conveyor feeds potatoes into the screen plane; its system makes it possible to separate many elements of blockages less than 20 mm in size, right up to the source of sorting. The sorting cell consists of a frame in which sieves and bulk are placed, which creates an acceptable distribution of potatoes into 3 fractions. Large potatoes that have not passed through the upper strainer are sent to the only stream of the bulking table. Potatoes that stop in the middle stage (sowing) enter the 2nd stream of the bulking table. From the bottom of the sifting sieve, small potatoes are directed into the supply channel and poured into a container placed next to the sorting. The sorting table assumes an integral system suitable for selecting two key fractions (large and seed) from spoiled potatoes and stones. Each of the streams is completed with a system that allows you to fix bales or nets in it, which makes it possible to continuously fill them with shoveled potatoes. The galvanic motor, located in the frame of the sorting chamber, uses a V-belt drive to drive the knee roller, which in turn swings the sieves using connecting rods. From the knee roller, the rotation then passes to the pulleys of the oblique conveyor drums and the bulkhead table. The main components of the sorting system are made of metal. Wood is used for the manufacture of ejectors, oblique conveyor slats, screen frames, sorting chamber walls and connecting rods.

In accordance with agrotechnical conditions, sieves with mesh dimensions are recommended:

— upper plane — 55×55, (50×50), (45×45)

— middle plane — 35×35, (40×40)

- bottom plane - a strainer with distances between the rods of 20mm. Using sieves with the significance shown in brackets results in:

- 50x50 - increase in the weight of elite food potatoes, exceeding the scale of sowing potatoes.

- 40x40 - reduction in the number of small seed potatoes, also elite, approximately 35mm in size.

A sorting set contains 5 sieves.

DIY potato sorter

The harvested potato crop is sorted before being stored for winter storage, and shortly before spring planting - small tubers are separated, which are fed to livestock or processed into starch. The potato sorter shown in Figure 1 allows you to mechanize this work. It consists of the following main parts: two paired rod cylinders, a loading hopper, pitched rod grids for various potato fractions, a manual drive and a frame. The base of each cylinder is made of wooden hoops with crosspieces. The hoops consist of individual elements connected to each other and to a cross with spikes and steel spacers.

How to make a potato sorter yourself

The device consists of the following main components:

- rod cylinders;

- bunkers for loading vegetables;

- metal mesh for various potato fractions;

- mechanism for adjustment;

- rack

The basis of each cylinder is a wooden circle with a cross. The wooden elements are connected to each other and to the cross with special tenons and steel spacers. To prevent mechanical damage to potatoes during sorting, the crosspiece is given a rounded shape.

Wood rods with a diameter of 1.5-1.6 cm and a length of 60-70 cm are attached to the hoops on the inside. The structural elements are made of durable wood. The rods are mounted to the hoops using screws or flexible metal tape. Recesses are made in the hoops.

Distance between cylinder rails for sorting potatoes:

- For a small batch of vegetables, make about 3-3.5 cm.

- For medium-shaped tubers - 4-5 cm.

- The internal diameter must be at least 70 cm.

The cylinders are connected with pins. Depending on the size of the cylinders, a frame of the appropriate size is selected. The part is made of wooden blocks with a section of 6 × 6 cm or angle steel 3.5 × 3.5 × 0.4 cm

During work, it is important to mount the cylinders at an angle of 8-10 degrees. Do-it-yourself potato sorting divides the tubers into three fractions: small, medium and large

The overall dimensions of the potato sorting machine given in the article are approximate. Depending on the required productivity and the size of the tubers, they can be changed.

Read also: How to cook pea soup without soaking peas

Today, there are a large number of options available to save time and effort at the stage of carrying out agricultural work such as sorting potatoes with your own hands

It is important to remember that making or purchasing a potato sorter yourself will significantly simplify and speed up the work, provide significant savings in resources and increase the quality of product packaging

It consists of the following main parts: two paired rod cylinders, a loading hopper, pitched rod screens for various potato fractions, a manual drive and a frame. The base of each cylinder is made of wooden hoops with crosspieces. The hoops consist of individual elements connected to each other and to a cross with spikes and steel spacers.

To prevent mechanical damage to potatoes during sorting, the crosspieces are made of a round shape.

Wooden rods with a diameter of 15–16 mm and a length of 650–700 mm are attached to the inside of the hoops. They are made of durable wood and attached to the hoops using flexible metal tape and screws. Recesses are made in the hoops for storing the rods.

The distance between the cylinder rods for small fraction potatoes is approximately 30.35 mm, and for medium - 40.50 mm. Inner diameter of at least 700 mm.

Rice. 1. Potato sorter: 1 - wooden frame; 2 - pitched board for coarse potatoes; 3 — cylinder shaft; 4 - manual gate; 5 - bearing; 6 - rod cylinder of medium-fraction potatoes; 7 — rod cylinder of fine-grained potatoes; 8 — loading hopper; 9 - pitched lattice of fine-grained potatoes; 10 - pitched lattice of medium-fraction potatoes; 11 - wooden hoop; 12 - wooden rod; 13 — cross; 14 — hoop element; 15 — steel plate; 16 — cross-shaped pad; 17 — hub with a locking bolt. The cylinders are connected with bolts. Depending on the size of the cylinders, the appropriate frame dimensions are selected. The frame can be made of wooden blocks with a section of 60x60 mm or angle steel 35x35x4 mm. During operation, the cylinders are set at an angle of 8.10°. Potato sorting divides the tubers into three fractions: small, medium and large. Small and medium potatoes are sequentially sifted through the first and second rod cylinders, and large ones are sent to the exit. The earth and small impurities are separated through the sloping grates.

Read also: Carrots beneficial properties for children

Potato sorting sizes are approximate. Depending on the required productivity and the size of the tubers, they can be changed.

For storage or sale after harvest, gardeners traditionally sort through potatoes, sorting them by variety and size. The work is slow and tiring. But there is a technique that was not so widespread, but has successfully reached modern villagers. A semi-automatic potato sorting machine for home gardens is easy to use and saves time, which is easy to do.

The master decided to create a homemade potato sorter. I looked at other models on the Internet and built a unit from scrap materials.

How to make potato sorting yourself

Authorization on the site

It consists of the following main parts: two paired rod cylinders, a loading hopper, pitched rod screens for various potato fractions, a manual drive and a frame. The base of each cylinder is made of wooden hoops with crosspieces. The hoops consist of individual elements connected to each other and to a cross with spikes and steel spacers.

To prevent mechanical damage to potatoes during sorting, the crosspieces are made of a round shape.

Wooden rods with a diameter of 15–16 mm and a length of 650–700 mm are attached to the inside of the hoops. They are made of durable wood and attached to the hoops using flexible metal tape and screws. Recesses are made in the hoops for storing the rods.

The distance between the cylinder rods for small fraction potatoes is approximately 30.35 mm, and for medium - 40.50 mm. Inner diameter of at least 700 mm.

Rice. 1. Potato sorter: 1 - wooden frame; 2 - pitched board for coarse potatoes; 3 — cylinder shaft; 4 - manual gate; 5 - bearing; 6 - rod cylinder of medium-fraction potatoes; 7 — rod cylinder of fine-grained potatoes; 8 — loading hopper; 9 - pitched lattice of fine-grained potatoes; 10 - pitched lattice of medium-fraction potatoes; 11 - wooden hoop; 12 - wooden rod; 13 — cross; 14 — hoop element; 15 — steel plate; 16 — cross-shaped pad; 17 — hub with a locking bolt. The cylinders are connected with bolts. Depending on the size of the cylinders, the appropriate frame dimensions are selected. The frame can be made of wooden blocks with a section of 60x60 mm or angle steel 35x35x4 mm. During operation, the cylinders are set at an angle of 8.10°. Potato sorting divides the tubers into three fractions: small, medium and large. Small and medium potatoes are sequentially sifted through the first and second rod cylinders, and large ones are sent to the exit. The earth and small impurities are separated through the sloping grates.

Potato sorter - drawings

How to make a potato sorter

.

The harvested potato crop is sorted before being stored for winter storage, and shortly before spring planting - small tubers are separated, which are fed to livestock or processed into starch. A homemade potato sorter allows you to mechanize this work.

It consists of the following main parts: two paired rod cylinders, a loading hopper, pitched rod screens for various potato fractions, a manual drive and a frame. The base of each cylinder is made of wooden hoops with crosspieces. The hoops consist of individual elements connected to each other and to a cross with spikes and steel spacers.

To prevent mechanical damage to potatoes during sorting, the crosspieces are made of a round shape.

Wooden rods with a diameter of 15...16 mm and a length of 650...700 mm are attached to the inside of the hoops. They are made of durable wood and attached to the hoops using flexible metal tape and screws. Recesses are made in the hoops for storing the rods.

The distance between the cylinder rods for small-fraction potatoes is approximately 30...35 mm, and for medium-sized potatoes - 40...50 mm. Inner diameter of at least 700 mm.

Rice. 1. Potato sorter:

1 - wooden frame; 2 - pitched board for coarse potatoes; 3 — cylinder shaft; 4 - manual gate; 5 - bearing; 6 - rod cylinder of medium-fraction potatoes; 7 — rod cylinder of fine-grained potatoes; 8 — loading hopper; 9 - pitched lattice of fine-grained potatoes; 10 - pitched lattice of medium-fraction potatoes; 11 - wooden hoop; 12 - wooden rod; 13 — cross; 14 — hoop element; 15 — steel plate; 16 — cross-shaped pad; 17 — hub with a locking bolt.

The cylinders are connected with bolts. Depending on the size of the cylinders, the appropriate frame dimensions are selected. The frame can be made of wooden blocks with a section of 60x60 mm or angle steel 35x35x4 mm. During operation, the cylinders are installed at an angle of 8...10°. Potato sorting divides the tubers into three fractions: small, medium and large. Small and medium potatoes are sequentially sifted through the first and second rod cylinders, and large ones are sent to the exit. The earth and small impurities are separated through the sloping grates.

Potato sorting sizes are approximate. Depending on the required productivity and the size of the tubers, they can be changed.

Khalimulina R.M.

DIY potato sorter

Before storing potatoes for the winter, they must be sorted and sorted. If there are a lot of tubers, the process can be mechanized: assemble a potato sorter yourself.

The device consists of several parts. These are 2 paired cylinders made of rods, a loading hopper, rolling rods, a manual drive and a frame.

Wooden rods with a diameter of 16 mm and a length of 700 mm are attached to the hoops from the inside. They are attached to the hoops using a flexible metal tape, after which they are tightened with screws. To lay the rods in these hoops you need to make small recesses.

The cylinders are connected with bolts. The sizes of the cylinders are different, which means that corresponding frames are needed. They are made from wooden blocks with a cross-section of 60×60 mm. You can use 35x35 mm angle steel instead, with a metal thickness of about 4 mm. The cylinders must be installed at an angle of 8-10°.

The sorter works this way. Small and medium potatoes are sifted through the first and second rod cylinders. Large tubers are immediately released. Of course, various debris remains from the potatoes (small fractions of soil, various impurities), but it comes out through the sloping grates.

Features of the root crop sorter and method

The mesh is here for filling the potatoes from the refrigerator. Hoops from an old washing machine. Trimmed 4 cm in width. Made 3 hoops. The axle is a 15mm pipe. I drilled holes and inserted rods from wire sixes. Got it with welding. There are no bearings here. Mesh size: square 50 x 50, chain-link 35x35, maybe 40 x 40. This depends on the size of your potatoes. Root vegetables are filtered into three fractions. It immediately pours out through the fine mesh. Then the seed. At the end the largest one flies out. Potatoes, passing through a 50 x 50 mesh, can be partly left for seeds, partly for food. The amount of work that was previously done manually without mechanization for several days can be completed in a few hours with the help of this sorting device.

The device is simple, made in haste. There are no complex mechanical components here. But the potatoes are sorted wonderfully. The fruits do not break. Size distribution occurs as needed.

Another option

When sorting potatoes by hand, when you sit and sort through them in the barn, you start throwing small ones, large ones and vice versa. The work is routine and quite boring. So isn’t it better to use the experience of craftsmen to make this work easier and make it an interesting event?

Why are potatoes sorted, sorting parameters

Before harvesting potatoes for the winter, they must be sorted by size, variety, appearance and other indicators important to producers or households.

Enterprises sort tubers according to the following scheme: 4-6 cm; 6-8 cm; over 8 cm. Potatoes that do not fall into even the smallest classification are collected separately.

Small potatoes from the first two groups are sent to store shelves, and larger ones are sent to vegetable markets. The largest, most selected tubers are kept by the harvesters for seeds and also supplied to public catering outlets.

Important! Sick and damaged tubers are discarded, which will quickly begin to rot and ruin the entire harvest. Also, when sorting, any plants, lumps of earth, stones and other debris are removed.

Mechanized and manual potato sorting

An important nuance of post-harvest processing is the sorting of potatoes into fractions. Modern agricultural enterprises that specialize in the industrial cultivation of vegetables try to automate this process as much as possible.

Specialized equipment sorts tubers according to given sizes quickly and accurately

It is important to remember that the exact speed and volume of sorting vegetables, of course, depend on the design model

Let's look at devices for sorting tubers, which make this process quick and as simple as possible.

Mechanized sorting

To perform mechanized calibration, a special sieve is used, through which potatoes of the required size pass. Devices can be manual or automatic.

The first type is more rational to use when the harvest is small. In this situation, mechanisms that you can easily build yourself are quite suitable.

Automatic sorters are often installed together with a tractor when cultivating a field.

Lattice device

When sorting small volumes of crops, there is no need to hire large-sized special equipment or come up with complex designs yourself. A table with a grid can provide sorting of potatoes in small quantities. A special drawer will serve as a tabletop for it. The sorting principle is based on the passage of tubers through a special grid.

Under the tabletop of the mini-potato sorting machine there are several boxes into which the already selected root crop will fall. A tuber of the required size falls into each tray

It is important to tilt the table a little so that the vegetables themselves roll down the slats and end up in the desired drawer.

A homemade design for sorting potatoes will be an indispensable assistant in preparing vegetables, but it has two significant drawbacks:

- Such a device does not ensure the selection of damaged tubers.

- A simple mechanism allows you to sort through a small volume of vegetables.

The overall dimensions of the wooden box must be at least 150 × 80 × 2.5 cm. The gaps between the beams should be approximately 35 cm at the beginning and 60 cm at the other end of the table.

Sort Options

Modern agricultural enterprises prefer to calibrate tubers by diameter into the following groups:

- 4-6 cm;

- 6-8 cm;

- over 8 cm.

Smaller potatoes are placed in 2.5 kg bags for sale in supermarkets, larger ones - in 20-25 kg bags for vegetable stores and markets. The largest potatoes are used by processing companies and catering establishments.

The mechanism and its effectiveness

There are two ways to sort potatoes:

Mechanized sorting is suitable for large harvests and consists of separating small tubers from large ones using a large sieve.

Mechanized sorting is divided into manual and automatic. The first is suitable for home harvesting for the winter, since it is slower, but cheaper than the automated one. The second type of sorting is used with special equipment and the crop is processed in tons.

Lattice table

One of the simplest, but at the same time quite effective means for saving time on sorting potatoes is a lattice table.

In essence, it is an ordinary wooden box with a lattice bottom. These are found on grocery and vegetable counters and in food wholesale stores. You can buy them or ask them for free from store employees.

The box will have to be modified a little by narrowing the bottom slats on one side so that larger potatoes can slip through them. This can be done using a regular or circular saw or hacksaw.

Attention! If you don’t have the opportunity to find a ready-made box, you can make it yourself from scraps of boards and bars, plywood.

Materials with a thickness of 30-35 mm are suitable. The length of the tray is not less than 1500 mm, the width is 750 mm, the height of the sides is not less than 250 mm, otherwise the potatoes will spill out even before sorting.

Potato grading in cylinder shape

This type of device is more difficult to make, but still possible. It will speed up the work and the amount of sorted harvest significantly.

For this you will need:

To make potato sorting, you need to place grids with holes of different diameters inside the cylinders.

Potatoes are separated into 3 fractions: small, medium and large. Small and medium tubers are sorted sequentially, and large ones are rolled out. Any debris that accidentally gets into the potatoes is sifted out using additionally installed small grids.

Mobile potato sorting L-701

One of the most popular mechanized machines is the L-701 mobile potato sorter. It is quite large in size and is designed to work on the field together with a tractor or autonomously.

The design of this machine allows you to sort tubers into small, medium and large. It consists of rubberized gratings with rectangular holes. The electric drive starts operation. Such equipment can handle a load of 5 tons of potatoes per hour.

Another fundamental difference from the cylindrical sorter is the size - at 7 m in length, the unit weighs almost 800 kg.

Sorter M-616

The most advanced potato sorting machine is M-616. It is much more complex in design - it contains a feeding conveyor belt, a heated selection table, a conveyor, a bag storage unit, and a support frame on wheels (which makes the unit transportable without any extra effort). This device helps to separate potatoes not only by size, but also to select seed ones.

This is a large unit that sorts potatoes into 4 parts. Its design allows the machine to be moved by one person. Such equipment can handle a load of 5 tons of potatoes per hour.

Potato sorting

Sorting for potatoes is an important event that allows good, high-quality fruits to be stored for a long time in a cellar or basement. Some people immediately select good, whole, not rotten fruits from the spoiled ones in the garden

Some carry out the sorting procedure under a roof, in a garage or shed. It is advisable to sort each batch that is collected from the garden.

Potatoes are sorted not only by quality and size, but also by color. You should not put large and small fruits in bags at the same time. Small potatoes are best left for livestock feed or as a last resort for making moonshine. The average one is used by gardeners as a seed fund. Large potatoes are eaten immediately.

How to make a sorting device with your own hands - step-by-step instructions and drawings

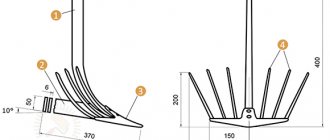

Another device, consisting of only 2 edged boards, can also be made independently.

To do this, the boards should be placed at an angle (Fig. 3) to create a gap that increases towards the bottom of the structure.

Smaller potatoes will fall out higher, and larger ones will fall out below.

Place containers for collecting sorted potatoes one after another under the boards so that the tubers of the required size immediately fall into a box or box.

Tips and tricks

If you do not have multi-ton reserves of your own potato harvest, you can safely rely on homemade sorting devices.

For homemade products, there is no point in buying or hiring a special automated sorting machine. A manual mechanism made independently will cope with the task.

A lattice table is perfect for small harvests. For more extensive work, you can make a cylindrical sorter that will serve you for many years.