The screw heads in the board are usually masked using putty of a suitable shade. This method is used by all home craftsmen and not only. The self-tapping screw turns out to be completely hidden behind a layer of putty, it is not visible, and the shade is almost the same. Is this disguise as reliable as everyone used to think? Most likely the answer is no. Such places need to be updated periodically. There is another interesting way to disguise the heads of self-tapping screws. It is more reliable, and the resulting result is almost eternal.

I drilled holes in the board in the wrong place. What to do?

- If the hole is not through

- If the hole is through

- Finally

It’s not for nothing that the saying goes: “Measure twice, drill once.” It happens that I measured everything several times, but still drilled holes in the wrong place. In most cases, you have to throw away the board and use a new one. What to do if the wood is butted against each other? In this material, Infosborka.ru gives practical advice on how to seal the wrong holes in wood - and so that they will hardly be noticeable.

How to repair a large hole?

Sometimes it happens that when repairing walls, not only pieces of plaster fall out. They may be joined by broken pieces of concrete or brick. In this case, it is necessary to use additional reinforcement of the wall surface.

- Similar to the previous cases, we clean the hole from everything unnecessary.

- We drive in dowels or screw in powerful screws. If the pothole is large enough, they need to be additionally tied with wire.

- Remove debris and dust with a dry brush or vacuum cleaner.

- Wet the surface with plenty of water.

- Add broken brick or crushed stone to a standard cement-sand mortar.

- Use the resulting mixture to seal the fallen piece of the wall, let the solution sit and dry.

- If necessary, we plaster the surface of the entire wall or locally a section of the hole, then dry it and repair the cracks.

- Now you can start finishing.

If the hole is not through...

Option #1

Now let the other side, which has no hole, become the front side. Thanks to this, the face of the part will again be flawless.

Option No. 2

Seal the hole with scraps of the same board. To do this, you need to make a plug from the trimmings. A plug drill, which is used to cut out conical plugs, will help with this. The resulting plug after sealing will be the least noticeable.

If you don't have a cork drill, use a round dowel that fits snugly into the hole. However, this option is a last resort, since such a plug will stand out strongly against the background of the entire part - especially after varnishing.

Option #3

- Using a router or circular saw, cut a wide groove (not necessarily deep). The main thing is that it covers the hole.

- Cut the strip to the size of the groove, but slightly thicker than the depth of the groove.

It is advisable that the plank be made from the same board, or match the color and texture of the wood that you are repairing.

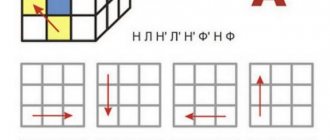

- Glue the strip into the groove as shown in the picture below.

- After the glue has dried, use a plane to make the surface smooth and then sand it.

And if the hole was near the edge of the board, then cut out the fold. The remaining steps are the same as described above.

Seal holes with toothpicks or matches

This method is the simplest and to perform it we will need regular PVA glue, matches or wooden toothpicks. Next, put together the required number of toothpicks so that they fit into the hole as tightly as possible, then dip them in PVA glue and insert them into the hole. Then take a hammer and easily hammer them into the hole until the end, leave until the glue has completely hardened. We cut off the remains sticking out of the hole with a stationery knife or a hacksaw, then clean it with sandpaper.

The aesthetic aspect of this method leaves much to be desired and may well be used in places where the hole will be hidden from view.

If the hole is through...

Option #1

- Using a cone plug drill, cut out two plugs. The height of each should be slightly less than half the depth of the hole. Otherwise, the plugs will rest against each other and stick out from the board.

- Install them so that the direction of the grain of the plugs and the board coincides. Then glue them.

Option No. 2

Cut out a rectangular piece that will have the irregular hole in it, and glue on a piece of the same shape cut from a scrap board or similar wood.

Option #3

If the wood has a pronounced texture (for example, oak or ash), then option No. 2 is unacceptable. In this case you need:

- divide the board into two parts by sawing it lengthwise

- then throw out the part where the hole was made incorrectly

- glue a board more or less suitable in texture.

In this case, the part will look like a glued shield. Which is also beautiful.

Gaps between floor and wall

This problem occurs quite often. Moreover, it can be either a house with a wooden floor or an apartment in a panel house. In any case, the problem must be solved: the sooner the better.

As for flooring made of boards, according to the technology of building construction, a small gap between it and the wall is necessary. This is a mandatory condition, since wood is a “living” material and can expand with high humidity or decrease in volume with dry air. In addition, this is also such important ventilation for wood. The initial width of the gap is in the range of 0.5-1 cm, the permissible increase is up to 2 cm. In the future, you will have to remove the plinth and eliminate the damage. By the way, skirting boards are effective for gaps of 1-2 cm, and their poor installation allows debris to accumulate between the floor covering and the wall, eventually destroying and deforming the joint.

To seal the gap, we dismantle the baseboard, thoroughly clean the gap from dirt and try to reduce its size. The choice of material to eliminate the defect depends on the depth and severity of the latter. Typically used:

- Felt (for caulking), jute, tow.

- Polyurethane foam.

- Plaster, putty.

- Acrylic or silicone sealant.

If the gap:

- Small (less than 3 cm). It is easy to seal it with plaster, polyurethane foam, cement mixture, putty .

- Medium (from 3 to 5-8 cm). Here it is necessary to use additional (preferably natural) materials - tow, moss, jute felt rolled into a “sausage” . They will add strength to the filling, and if processed, for example, in formaldehyde, they will prevent the appearance of insects in the future.

- Large (more than 5-7 cm). To fill the voids, the following are suitable: polystyrene foam, pieces of brick or wood . The main thing is that the filler is not very fine, covers a larger area, but does not make the gap wider.

When the gap is filled with auxiliary material, you can fill it with construction foam, cement mortar, etc.

If, when eliminating the gap, there will be plaster on top, then pieces of wood cannot be placed in the recess. They will absorb moisture from the solution, which can cause rotting, swelling, and mold.

After complete drying, excess material is removed, surfaces are cleaned, finishing work is carried out, and if desired, the baseboard is installed.

Finally

If you made a mistake with the holes for the handles - that is, they are small - then you can buy restoration wax at furniture stores and rub it into the wrong holes. Next, remove the excess and wipe with a cloth until smooth.

When building your own home, it is not enough to pay attention to what materials are used for this - you also need to be very careful about the method of attaching these materials. As you know, any building material “requires” its own fasteners and method of its application. The floorboard is no exception in this regard. Considering the loads that fall to its share, the choice of method of fastening the floorboard simply cannot be an insignificant issue. Indeed, if the boards are not fastened well enough, after a short time they will begin to “demonstrate their dissatisfaction”, loosening and changing their position, and the initially smooth and even plank floor will not only begin to creak underfoot - it will literally fall apart into individual components.

Sealing cracks in rounded logs/beams

The conversation about correcting wood defects cannot be considered complete if we do not touch upon the topic of the appearance of holes and cracks in log houses. For this reason, we will answer the most popular questions related to this topic as briefly and informatively as possible.

Questions:

- Do I need to seal cracks in timber? Sealing holes and cracks in log logs is not just a matter of beauty, but along with interventional insulation, their sealing will be an important technological stage in the construction of houses. Repaired cracks will reduce the level of heat loss of the building, and can also prevent the accumulation of moisture and the appearance of biological activity inside the logs, which significantly extends the service life.

- How to seal cracks on the outside? To insulate between the crowns and seal cracks, materials such as special sealants are used. They have a wide range of operational advantages - resistance to frost, vapor permeability, resistance to UV rays, biological activity, etc. But the main feature is a high degree of elasticity, due to which the insulating seam will deform along with the wood and will not tear or crack.

- How to properly seal cracks? The sealing technology will be identical to how to seal crown gaps. A special polyethylene foam cord should be placed inside the crack using a spatula. Depending on the size of the split, you should select the required diameter of the insulation cord. To ensure reliable fixation in the crack cavity, it must shrink by about ¼ of its original diameter.

Next, cover the crack on both sides with masking tape. Using a special gun with a narrow nose, fill the crack cavity with sealant, and this should be done evenly. The seam must be tight, the formation of voids and bubbles is unacceptable. The filled seam should be smoothed with force with a spatula dipped in water and excess sealant should be removed. Upon completion of work, the seams must be protected from moisture for at least 24 hours.

What fasteners are used to secure the floorboard?

Today, manufacturers produce special screws for floorboards, which ensure reliable fastening of the board to the base and guarantee a long service life of the flooring without any additional investments in its repair.

However, it is worth noting that such self-tapping screws are somewhat more expensive than conventional fasteners used in construction.

But at the same time, they perform their work very efficiently and as efficiently as possible. As a result, the entire floor covering will last much longer than if conventional screws were used to attach the boards. Saving on self-tapping screws in this case is an almost guaranteed need to repair the floor in the very near future. And on the boards themselves, fasteners that are not specifically designed for them can have a very negative impact - for example, screwing such fasteners into the board can cause a crack.

Drilling a hole for fasteners

The fastening area in which the screw needs to be hidden (for example, the corner of a tabletop) is drilled through. To do this, perpendicular to the surface located under the chip, a thin drill is used to mark the place of screwing in, completely passing through the upper part.

You also need to make a hole in the lower fastening element. Its depth here should correspond to the length of the screw, taking into account the thickness of the main (upper) part without a chipped piece of wood.

To prevent the drill from going deeper, wrap it with a piece of electrical tape, limiting the stroke to the part free of electrical tape. Place the parts to be joined together. Through the hole in the top, use a thin drill to mark the course of the screw in the bottom part to the desired depth.

Remove the top part. The holes of both elements that will be connected are widened with a thicker drill, but slightly smaller in diameter than the screw.

Now you need to deepen the cap. The upper part of the space for the screw is expanded with a drill of the diameter of its head to a depth that will allow the head to sink into the surface.

You can use a Forstner drill for this purpose. As a result of this operation, the chipped piece will then fall into place without interference.

An experienced craftsman usually makes a hole at once on both parts that will be connected, joining the fastened block before drilling. But in the case, for example, of attaching legs to a tabletop, such work will have to be done in weight, which is beyond the capabilities of a beginner in carpentry.

Seal holes in wood

All self-tapping screws have a special protective coating that prevents the possibility of corrosion on their surface.

And you can find out the special screws for attaching the floorboard very easily - there is a milling cutter at their tip, which allows you to screw these screws into the board without first drilling the holes. This allows for a more “tight” fit of the self-tapping screw itself, and therefore a more secure fixation of the board to the base.

In the same case, if you pre-drill a hole for a self-tapping screw on the base of the floor, spontaneous unscrewing of the self-tapping screw may occur, and it is not always possible to select the correct diameter of the drill for the subsequent “fitting” of the board onto the self-tapping screw.

How to prevent cracks from appearing

It’s not for nothing that they say: “Forewarned is forearmed.” So in this matter: it is better to follow all the rules for laying the floor, regularly carry out inspections and take the necessary measures.

- Laying is carried out taking into account the correct ratio of the thickness of the boards with the gap between the logs.

- There is a gap between the wall and the floor covering along the entire perimeter of the room.

- The joints of wooden surfaces are covered with damping gaskets as a means of shock absorption and preventing squeaks.

- Wood products must be coated with antifungal and water-repellent solutions.

- In order to prevent moisture from appearing under the floor, it is possible to organize natural ventilation.

Some tips for installing floorboards.

- The distance between individual screws when attaching a wooden board to the base should be from 25 to 30 cm.

- Some craftsmen recommend using a special glue when laying floor boards on a horizontal base, which is used when laying parquet. This is a completely possible option if there is no additional waterproofing layer between the boards and the base - for example, a moisture-proof film. But at the same time, it is important to know that special glue can only be an additional way to fasten the board - the main method is still self-tapping screws. Without them, it is simply impossible to achieve a sufficiently reliable fastening.

- When ideally connecting flooring boards to each other, we must not forget that the flooring should not fit closely to the walls of the house along its entire perimeter - about 7-10 cm of free space should be left between the edge of the covering and the wall.

- It is possible to completely “hide” the screws used when installing a wooden floor. To do this, you need to “recess” the head of the screw into the board a few millimeters, and “mask” the resulting hole using a piece of wood of a suitable size and shape, the species of which must match the species from which the boards are made. Some manufacturers of luxury building materials produce similar “stoppers” that are included with the boards themselves.

Often, when choosing wooden panels, such as eurolining or false beams, purchasing them significantly hits your pocket.

Or if we are going to update the interior of our summer garden house, we don’t want to waste too much.

It is no secret that molded products are sold under different grades, differing in wood defects and price. For some, it is fundamentally important that the wooden panel be knot-free, while others like the natural pattern of wood with knots.

But there is another option ideal for finishing summer houses and workshops, the so-called 3rd grade.

Grade 3 usually includes small cracks and holes from fallen knots. Of course, such panels do not look “presentable” on the wall, to put it mildly, but often their cost is very tempting.

Third-grade panels are very easy to adjust with your own hands, and no expensive material or equipment is required.

Let's consider this option step by step:

We install the third-grade panel you purchased on the wall, just like any other expensive one. For installation, you can use special fasteners (clamps), or you can save money and mount the panel on regular mounting nails, driving them in every third panel. However, the quality of installation will not change in any way.

Small cracks and chips in the panel are covered with a special mastic to match the color of the wood, using a plastic spatula.

Methods for eliminating gaps

Wood coatings have been known for a long time, as well as their disadvantages and problems that may arise during their operation. There are many methods for eliminating cracks in a wooden floor. First of all, let's consider the most accessible, simple, well-known folk methods.

Reinforced tape

The best option for very quickly getting rid of small cracks and crevices in the floor.

To apply a 50 mm wide tape, you must thoroughly clean the floor covering from grease and dirt, wash it well and dry it. The gap is closed with tape, the edges of the latter are fixed with a stapler. Everything is quite simple, except for one nuance - stripes of adhesive tape. It is better to cover them with a rug, path, carpet, etc.

Linseed oil and wax

A very simple way to counter shallow, small-sized defects in boards. Both components heat well, mix into a homogeneous substance and pour the latter hot into the cracks. After cooling, level the surface.

Gelatin, shavings, gypsum

Pour table gelatin with warm water and leave until it swells, then obtain a homogeneous mass. Add gypsum and fine wood shavings to the gelatinous substance, mix well, and place the resulting mixture in the cracks. After the solution has dried, the residues are cleaned, removed, the surface is sanded and decorated with paint or enamel.

Paper, copper sulfate and paste

One of the most accessible methods.

The algorithm of actions is quite simple:

- Paper (not glossy) is shredded into pieces (torn, cut), filled with water and left to soak.

- A paste is prepared from water and starch (flour).

- Copper sulfate is added to the resulting “jelly” at the rate of 1 part of the substance per 10 parts of paste. In the future, the additive will protect the putty from small insects.

- The paper is squeezed out well, added to the paste and the whole mass is brought to a homogeneous state.

- The resulting mixture is spread onto well-cleaned cracks, compacted to the required depth, and the surface is leveled.

- Over time, the well-dried composition is treated with abrasive materials and painted.

Wedge slats

Not to say that this method is completely simple, but it is practical, popular, and gives excellent results when repairing even large defects.

The process goes as follows:

- Similarly to all the mentioned methods, all dirt, dust, etc. are removed from the surface of the floor, cracks, and the edges of the cracks are made smooth.

- Prepare the slats: it is best if it is pine wood, the inserts become narrower towards the bottom, and the width is 0.5 mm less than the width of the gap.

- Prepare the gap: use the tip of a screwdriver to guide it along the entire length, applying force. The procedure is repeated several times.

- Glue (PVA) is added to the defect and leveled well so that it fills all the voids. The sides of the wedges are also lubricated.

- The lath is inserted into the gap with a hewn edge and beaten with a mallet or hammer so that it goes deeper into the gap.

If you use a block of wood as a spacer between the hammer and the strip, then you don’t have to worry that the latter will leave dents after impacts. The joints, if desired, can be covered with masking tape.

- There are voids left - they can be easily filled with a homemade mixture of sawdust and glue.

- When the glue is completely dry, the edges of the wedge that protrude above the floor are removed using a hacksaw, plane or knife. The repair is completed by sanding with sandpaper (fine-grained) and treating with varnish, paint, stain, and oil.

Tow, rope, cord

A time-tested method.

Moreover, it is used to eliminate gaps not only in the floor, but also in wooden walls. The primary task is the correct choice of cord (rope, twine) of the required length and diameter. The thickness of the material must be greater than the width of the gap. In addition, you will need: glue (carpenter's glue, PVA), putty and sawdust. The step-by-step action plan is as follows:

- It is good to soak the rope with glue; you can even immerse it in the adhesive composition and hold it in it for a while.

- Without wasting time, mix glue, putty and fine sawdust.

- The cord is placed in the crevice and deepened 3-4 mm using a hammer, core or spatula.

- With the mass prepared in advance, it is necessary to fill the remaining space to the top with a reserve. It is taken into account that the mixture shrinks during drying. As a result, the former gaps are well cleaned and painted to match the floor.

An analogue of hemp rope can be plumbing flax tow. It is also compacted into the cracks after impregnation with glue.

You can purchase synthetic sealing cord at hardware stores. The material of manufacture is foamed polyethylene, the cord itself does not require glue, it is compacted into the gap by 4-5 mm, covered with putty on top, the optimal coating is an oil-based composition for wooden products.

The proposed method is effective in combating squeaking in floorboards

Sawdust and glue

You can successfully seal cracks using just two components. To get a working mixture, take PVA glue and sawdust, preferably of a fine fraction. Pour boiling water over the latter, mix thoroughly, and leave for 1-2 hours to swell. The next step is to add glue to the resulting mass (PVA can be replaced with carpentry glue, and to speed up hardening, choose epoxy) to obtain a viscous, viscous substance. It will become a homemade putty for eliminating cracks in the floor. The mixture is applied with a spatula, leveled well, and after 2-3 days required for the glue to dry, sanded.

Sawdust and cement

One of the varieties of the previous mixture. To create the composition, first mix glue and warm water in a ratio of 2:15. Then we supplement the mass with cement and sawdust, 5 parts each. Mix all components thoroughly, let it brew for 5-7 minutes and seal the cracks. For the best effect, use the mixture warm (heated). The advantage of the method is good insulation, the disadvantage is a long drying time.

Sawdust and paint (varnish)

Another composition with sawdust. Take 1 part each of wood varnish and paint, add 4 parts of sawdust (fine shavings). We seal the cracks with a homogeneous composition: 1 time - small ones, several times - large ones.

Cement and broken glass

The cement-glass mixture is relevant if there are rodents in the underground. Not every poison will do. It is better to choose poisons with mummifying properties, otherwise the smell of decaying mouse corpses will be impossible to eliminate. In addition, rodents can cope with many solutions without problems, but broken glass is too much for them. The cracks are filled with a mixture of fragments of bottles and concrete, and a layer of putty is placed on top.

Those who don’t want to tinker with glass can safely use pieces of wire as filler (even cut metal items for cleaning dishes). But stores offer professional building mixtures based on concrete with the addition of aluminum chips.

Epoxy cement mortar

A simple and reliable tool. Cement and epoxy glue are mixed 1:1 and, until the composition has hardened, quickly pour it into the gaps. The cracks are filled with a small margin, and after drying, the excess is cut off and the floor is decorated.

Plywood and chipboard

When we are not talking about minor damage, but about a significant distance between the floor boards, it is hardly possible to save the situation with mixtures or solutions. You need to act differently and use chipboards, plywood, and only then organize the coating with finishing materials. There are several ways to fasten sheets: using liquid nails, dowels with self-tapping screws, ordinary nails. As a rule, the caps are sunk into the base, and then everything is leveled with putty. The advantages of this method are a flat floor for any covering, insulation, not a single crack. Negative aspects are labor intensity; for large affected areas, significant investment in materials.

Screed

Deformation occurs mainly due to drying out of the wood and the formation of large cracks. To tighten the floor, it is necessary to dismantle the boards. The latter will be installed anew, but with displacement, compaction and the addition of 2-3 floorboards. The work is carried out using a jack, wooden wedges, clamps, and a special lever. The boards can be laid thoroughly, reliably and efficiently, and the floor will serve the owners for a long time.

Now let's move on to more professional means.

Putty

Have the first small cracks appeared?

Factory putty of various types will come to the rescue: finishing, filling, leveling, sealing, universal. It also makes sense to get recommendations from specialists, since there are different types of compositions:

- It is recommended for wooden floors as it smoothes out various defects, unevenness and small cracks.

- Pigmented (for wood) is available in different colors (beech-oak, teak-mahogany, etc.), it is necessary to check the match between the specified and the actual color.

- For parquets it is made on a solvent basis.

- Elastic – the best option for joints and “floating” gaps.

- Oil-based – reliable, practical, despite the long drying time. The base is chalk, water, oils.

- Acrylic – environmentally friendly, fire resistant.

- Polymer is harmless (water base), holds tightly, dries quickly and does not crack. The mixture (in reasonable quantities) is applied to the floor and pressed into the cracks using a spatula. After the material has dried (the exact time for a specific type of putty is indicated on the packaging), the surface is cleaned and leveled with sandpaper.

Polyurethane (construction) foam

Blowing out cracks with foam is a very simple repair method.

In addition, the composition will not only help get rid of defects, but also enhance the heat and sound insulation of the floor. Since foam is used quite often, it is necessary to clarify some of the nuances of working with it:

- In order for the mass to adhere well to the surface of the gap, its surface must be slightly moistened. To do this, you can take the simplest spray bottle (mechanical) or a plastic bottle with holes in the lid.

- The optimal temperature for working with the can is 5-25 degrees Celsius.

- Be sure to take into account that polyurethane foam tends to expand. Moreover, the composition intended for use in special “guns” (replaceable cylinders) lays down more accurately and swells less than the foam in disposable cylinders. Therefore, it must be applied little by little, very carefully.

- We should not forget that foam is a caustic material in use, although, after stabilization and drying, it is harmless to humans and does not emit toxic substances.

Sealant (acrylic, silicone)

If there is a need to find a composition to eliminate narrow or wide cracks, the sealant will be a real godsend. The nozzle cap, shaped like a syringe, makes it possible to easily introduce and distribute the composition inside the recesses. With proper preparation of problem areas of the floor and installation of sealant, the latter will serve faithfully for many years.

To “reanimate” wood, two types of sealant are used:

Acrylic

The composition is easily washed off your hands (water base), odorless, transparent. It adequately withstands high humidity, and after drying it can be easily processed - sanded, painted or varnished. When choosing this material, you should pay attention to some points:

- Characteristic shrinkage.

- Instability to temperature changes (the optimal use case is a heated room).

Silicone

The material is elastic, and this is one of its main advantages. When the floors “play”, “walk” and cannot be securely fixed in any way, silicone sealant will come to the rescue. The composition has excellent adhesive (penetrating) properties and is resistant to compression and stress. The disadvantages of the material include the almost impossibility of coloring it, although specialized stores offer a considerable selection of products in various colors.

The sealing procedure is as follows:

- We clean damaged areas of the floor, edges of cracks, and joints from dirt.

- We insert the tip of the balloon into the gap and carefully fill the space with an even strip.

- Using a narrow spatula, level the composition, removing excess.

- After drying, the surface is sanded and painted.

The question often arises about eliminating cracks in cork parquet. It is important to clarify here that the material, in principle, as a type of laminate, has a characteristic structure of several layers. The thin top plate made of balsa bark makes it impossible to apply technology to ordinary wood

It is worth mentioning separately the deflection of the boards , which can also lead to the appearance of cracks and significant deformations. Causes of the problem:

- Incorrect lag installation step.

- The finishing material is too thin.

To correct the situation, it is necessary to connect adjacent boards with dowels.

- We make a corner hole in the adjacent boards.

- We insert wooden rods soaked in glue into the finished hole and tighten the boards.

- When the glue dries well, remove excess parts and sand the surface.

How to fill blind holes in wood with your own hands

Such mastic

Available at any hardware store, on average a tube of such mastic costs 100-150 rubles. Or, you can save money again and mix regular PVA glue with sawdust. The quality of such “homemade” putty is often no worse than purchased mastic.

All that remains is to remove the large holes from the fallen knots. Again, nothing complicated here.

Using polyurethane foam, we foam the large holes in the panel and let the foam harden. After the foam has dried, cut off the excess with a knife or blade, and cover the foam with the same putty (mastic or homemade mixture).

After these steps, let the mastic dry for 1-2 hours and sand it with fine sandpaper.

Further, at your discretion, you can protect the panels from external factors by covering them with an antiseptic or varnish.

Thus, you can renovate your home using elite types of wood, paying a minimum of money for it and spending very little time.

On average, by purchasing wood panels of grade 3, you save up to 60%, while not being inferior in appearance to panels of grades 1 and 2!

You can see prices for different types of molded products in the price list of our website.

This video shows one of the ways to hide a self-tapping screw in wood. Video on how to make boats

GEORGE KAPIN:

Should I just drill 4 wooden wedges, grab them and sand them? The plug is attached to the glue and does not bear any load, why is this jerking off?

Vyacheslav Filimonov:

cool) but why such a hassle when it can be made so that it fits tightly and with glue. And then press it through the post with clamps, fix it purely symbolically, to give it strength.

Dinar Khaybrakhmanov:

I like the lining of the pillar with a figured lath, how do you do it?

Vladimir Davydov:

Volodya, the balusters look like a multi-story birdhouse. Tell me, can shields be processed with this grinding machine? I mean shields glued together from planks. Or is only a surface planer, or whatever else, suitable?

shturer:

Can you make a video about the tricky table?

There is no extra:

A good option! takes place in life.

Veaceslav Lefter:

Somehow, all this takes a long time.

Valentin Lisanov:

What for?

Alexander Shuvaev:

Aren't 2 screws enough?

Sergej W:

It would be possible to install round plugs this way. And the built-in will issue

alex sokolov:

Well done. Good luck to you in your creative work and good health.

Timur Yusupov:

I'm puzzled.

How to seal a small hole?

With blind recesses on the inside we proceed as follows: we expand the defective area onto a cone with a hammer drill, and the base should be deep in the wall. We remove dust from the recess with a brush or pump it out with a vacuum cleaner. Mix the plaster or sand-cement mixture (3 to 1), obtaining a solution of medium humidity (slightly thinner than plasticine).

Before filling the hole in the wall, inject about a quarter liter of water into the channel. The walls must get wet, otherwise they will draw moisture from the plaster or cement, causing a crack to appear. We take a little mortar on a spatula and press it into the wall, moving the tool parallel. We continue this operation until the recess is completely filled. We glue a reinforcing mesh onto the damaged area (usually it is used to glue the joints of drywall sheets) and putty the wall using the same solution.

If the channel is located on the outside, then the elimination of this defect will proceed according to the following scheme: we expand the recess, removing loose concrete, and remove dust with a vacuum cleaner or brush. Mix the solution (one part sand to one part cement), and fill the recess with this mixture. We restore the thermal insulation layer and install a waterproofing patch using hot mastic or tar. Very small defects (from dowels or similar) can be repaired with polyurethane foam without cleaning or moistening. After hardening, the foam is cut off and sealed with mastic or wallpaper.

How to fill a hole in furniture so that you can screw a self-tapping screw in there?

It’s easier to make a patai so that the cap is not visible and then cover it with wax or wood putty

Sergey Naumov:

Greetings! Professional roofing mallets are available. 1000 rub. 89040580960 Sergey.

Mr Nab:

It’s good when there are tools and machines)

Onla T:

The main thing is fast, easy and without any hassles!

HOBBY WORLD:

Well done

Sergey:

I make it simpler, cheaper and less noticeable

Alex:

Fucking smart idea.

Leonid Lakizo:

And I forgot to drill 2 mm holes for screwing in self-tapping screws, and I haven’t heard anything about putty based on the same wood and PVA glue, and a special attachment for a drill that removes the chamfer by creasing the chips for subsequent plaster, which even preserves the grain of the wood, at StudioKmebel for such screwing self-tapping screws into furniture with a lifetime guarantee - they would have been fired. ...

Tool preparation

All of the described methods for sealing holes in wood will require the use of tools that every owner should have.

- Putty knife;

- Hacksaw with blade for metal;

- Hammer (preferably a wooden mallet);

- Wood drills or milling cutter;

- Sandpaper.

Safety precautions have also not been canceled, so we definitely arm ourselves with gloves and eye protection.

A popular bookmaker has launched a mobile application for Android,

download 1xBet

You can follow the link absolutely free of charge and without registration.

Video on this topic

How to hide a self-tapping screw

This video shows one of the ways to hide a self-tapping screw in wood. Video on how to make boats

.

Let's say we need to fill a small chip in a wooden stock (my case).

To do this, we need two “ingredients”: baking soda and liquid cyanoacrylate glue. The first, I think, can be found in any kitchen, the second is sold in hardware stores, construction stores and large chain markets.

Manufacturers and type of packaging may be different, but one thing is important - the base. That is, it is cyanoacrylate. Nothing else will do.

(Immediately a warning for those who are not in the know: this glue is very poisonous, as can be seen from the name, and besides, it hardens instantly in the air and tightly grips together the surfaces that it comes into contact with. Including your fingers. It is best to store cyanoacrylate in the refrigerator, i.e., together with food, so be careful.)

Let's begin the process of repairing the chip in the wood.

First: add a drop of cyanoacrylate into the chip cavity. Here it is important not to overdo it and not to flood the neighboring areas - the glue flows like water, we will be tortured to scrape it off later. Personally, I dripped from the bottle onto the head of a match, holding it over a napkin, and then transferred this drop to the treated area. Now we take a little soda on the tip of a knife and pour it into the cavity. If you have poured too much, remove the excess and drop a drop of cyanoacrylate onto the soda crystals. The resulting composite instantly “stands up.” Shake off/blow away any excess crystals that did not fall under the drop, and see if the chip is completely filled.

You cannot pour in the entire required volume of soda at once: the glue will harden before it has time to saturate it - so, for example, a depression 2-3 mm deep. filled in layers, in 2-3 steps.

That's the whole algorithm of actions. Next, the composite “cork” is polished: with needle files, emery, a drill, abrasive sponges, or all of these in turn - it all depends on the area of the surface to be treated and the geometry of the object: in a word, everything is as usual with ordinary putty, for example, based on epoxy resin.

This putty, however, has a number of strong advantages over both epoxy composites and ready-made putties (for example, water-based). 1. The cyanoacrylate-based composite is ready for further processing immediately after puttying. 2. During this treatment, it does not chip or wear out, unlike soft ready-made putties, and also, unlike epoxy compounds, it does not “flow” from the heat imparted to it by the friction of the abrasive.

3. It has incomparably better adhesion compared to many other putties. 4. Possessing high strength, hardness and at the same time sufficient ductility, it allows you to model clear, rather than slicked, geometric differences using ordinary needle files, etc. 5.

Wood putties

Wood putty is a paste-like composition that is used to cover cracks, as well as fill in recesses in the form of holes and level the surface of the material. Puttying is by far the most popular method for eliminating defects in wood due to its accessibility and simplicity. This technique has a number of undeniable advantages, but you will need to familiarize yourself with some nuances in advance. Due to their viscosity, putties perfectly fill depressions and cracks. After drying, which occurs very quickly, the material gains excellent strength and can be subjected to standard woodworking procedures - sawing, sanding and planing.

All coatings that form a film - varnishes, paints and enamels - fit perfectly onto the frozen layer of putty. Due to the different tinting options, you can easily choose a putty to match the wood you are restoring - this will be especially important when further applying stain, varnish or even wax.

Putties can be divided into two main types:

One-component putties are those putties that are made on the basis of an alkyd, water-based or other type of binder that are offered in finished form. Such materials are as practical as possible, and they are also accessible - all you need to do is mix the paste-like mixture, and you can start working. The relatively long “life” of the mixture makes it possible to slowly repair large areas - sealing cracks in a wood floor or leveling other surfaces with a large area.- Two-component – compositions that are offered in the form of two separate components (hardener and putty). They should be mixed immediately before starting work, and the recommendations given by the manufacturers should be strictly followed. They differ from one-component putties in a higher level of strength, excellent elasticity, almost complete absence of shrinkage and resistance to solvents/water.

But the disadvantages are mostly relative - high cost and rapid hardening. The “lifetime” of a two-component putty is approximately 4 to 6 minutes, and this can create certain inconveniences when working with large areas, and therefore they are considered to be a material for local repairs - covering small holes and cracks in a relatively small area.

Seal a hole drilled in wood

Being not yet completely sanded, it can be painted well even with water-based compounds, such as potassium permanganate, not to mention nitro and other stains or enamels. 6. Excellent grinding and polishing. 7. Does not shrink. 8. Allows gradual build-up of the layer to absolutely any desired thickness.

Using the described method, I repaired a small (approx. 4x3 mm) chip in the PPSh wood, which formed when removing a skewed dowel nut. No matter what I tried, the trace of restoration remained noticeable. And not only because of the different color shade in this area, but also because the water putty partially “removed” during sanding and a noticeable depression was formed, and when using Epoxy composite glue under the finishing treatments, a too obvious border became visible along the edge of the putty chip, and this glue did not want to stick well. And here is the result with soda and cyanoacrylic glue. Before processing, this area looked something like this (reconstruction in Photoshop):

Of course, a slight difference between this area and the main surface is observed, but only if you know about it and look specifically at it, it can rather be mistaken for a fragment of a knot that was partially “removed” during countersinking or the like, a natural violation of the homogeneity of the wood structure. During the subsequent processing of the area, of course, tinting and “micro-painting” were used with tinting paste and a solution of potassium permanganate (that is, the compositions that were used when tinting the stock itself were used).

I don’t know why soda is recommended as a filler. Possibly due to the appropriate grain size. Any powder like wood powder with this purpose. too thin and its individual particles will stick together, not allowing in the glue, which in the case of soda crystals has the ability to envelop them and thus hold them together. Other fillers, such as salt, may also work. But not sand, which is too hard for abrasive processing, not flour, because it is hygroscopic and rarely dry, not sugar, the crystals of which are too large. In any case, the method works great.

Hi all. In today's article we will look at several methods of how to fill blind holes that are drilled in wooden blanks. For this experiment, 6 wooden blanks have been prepared, the holes of 3 of them will be filled with special compounds, and plugs will be installed in the remaining 3. Each of these methods has its pros and cons. I tried to describe them in detail.

Note: Each sample was sanded with 150 grit sandpaper prior to the final visual test.

Below is a list of what I used in my experiments.

- Ryoba saw (universal double-sided Japanese saw);

- Rasp;

- Sander;

- Device for connecting with self-tapping screws (Kreg Jig);

- Automotive putty;

- Magazine plugs;

- Wood putty;

- Dowels with a diameter of 10 mm;

- Wood glue.

The first method is to use traditional wood putty. It's very easy to use. I just filled the holes to the brim with putty and then set it aside to dry completely.

The holes are deep, so I let the putty dry overnight. I thought that it would crack or simply dry out, but the putty did its job perfectly. After sanding it became very smooth.

Repair by sealing the hole with metal

Metal patches and subsequent soldering are considered the most productive means for restoring thresholds, even with a large area of corrosion. If rust has not led to deformation of the central pillars and distortion of the geometry, then you can use metal patches and strengthen them with a soldering iron. For repairs you will need the following materials and tools:

- metal patch, size 2 cm larger than the corrosion hole.

- assembly hammer;

- Bulgarian;

- medium abrasive sandpaper;

- anti-gravel;

- anti-rust composition - phosphoric acid, if available;

- soldering iron, tin solder;

- automotive primer, degreaser.

Preliminary work begins with treating the surface with a grinder after the used paint layer has been cut off; for this you need:

- Clean the thresholds and identify areas of corrosion.

- Cut from metal, you can use cans of auto chemicals, patches of the required size.

- Service the edges of the patch and treat the threshold with a degreaser.

- Solder the patch using a continuous seam.

- If the metal protrudes above the surface of the body, press the bubble with a hammer.

- Treat the dent in the metal with a primer, leveling the entire surface. Use phosphate primer for the first layer. After 10 minutes, apply standard automotive grade.

- Let it dry. Sand, apply a layer of paint and varnish.

How and with what to seal the seams between plywood on the floor

On plywood flooring you can often find seams and joints that need to be eliminated. You need to know that the most important thing in choosing a putty is elasticity, since plywood consists of wood veneer, and the wood is subject to seasonal deformation. Over time, the plywood dries and the joints become more visible. It is also worth choosing putty according to the color of the wood, as well as a special one, that is, for wooden material.

To seal seams, use:

- Acrylic putty;

- Elastic sealant;

- Hot melt adhesive;

- Sawdust with PVA and gypsum;

- Epoxy adhesive.

To seal the seams between plywood on the floor, you need to choose exactly the putty for wooden floors, since the other simply will not withstand the load

It is worth considering that chipboard and plywood must be well secured so that they do not move or vibrate, then the chosen putty (putty for wooden floors) will not crack and will hold tightly, closing the gap.

This work is also done for plywood, on which linoleum will subsequently be laid.

You should also cover dents in the plywood and all joints and cracks with putty or better yet, silicone sealant. Plywood needs to be coated with an antiseptic. Before laying linoleum, you need to pay attention to the evenness of the plywood and its cleanliness.

Factors influencing the appearance of cracks

And finally, to prevent cracks from appearing, you need to know the reasons for their formation. Such knowledge will also help eliminate their consequences. So, the appearance of cracks can occur due to:

- low-quality raw materials (for example, if the boards are damp and laid on the floor, over time they will begin to dry out, forming spaces);

- increased dryness in the room and the prevalence of high temperatures. Optimal indicators: humidity 45-65%, and temperature - no higher than 25 degrees;

- unsuitable material that was used for laying the floor. Ideal raw materials are species of coniferous and tropical trees, as well as oak boards;

- rodent settlements. Only in this case the cracks will be equal and uneven. The best way to eliminate such problems is to completely replace them with a new board.

There are many other reasons why cracks may appear in boards. In any case, it is better to eliminate them while they are small in size.

Inexpensive methods to help remove gaps between boards

Often, before carrying out repairs, owners discover unwanted defects in the form of gaps between the boards. This usually happens at the most inopportune moment, when funds in the budget are severely limited and there is nothing to allocate for major repairs. In this section we offer several low-cost and very effective options for eliminating defects.

Large gaps between boards are best sealed with products with good viscosity Source phonoteka.org

Installation of rack wedges

You can always turn slats yourself from leftover timber or fresher boards that you have on the farm. They need to be planed so as to obtain a wedge-shaped shape, and the width of the slats should be 0.5 mm larger than the size of the gap between the boards.

Before placing the wooden piece, the gap is thoroughly cleaned, and dust and debris are removed using a vacuum cleaner. Then apply wood glue to the wedge of the slats (PVA will also work). It is also injected into the gap in a small amount. Next, use a rubber mallet to hammer the batten in so that it fits as tightly as possible between the boards. You can use a hammer to hammer in, but you need to put a rubber or thin block under it so as not to make even more holes in the floor.

Existing ways to do this kind of work

When screwing a long self-tapping screw into wood, the head quite often breaks off. The slots on the bit or screwdriver may also break off. Many will say that it is easier to pre-drill a hole for a screw, but this option is not always available. Often a drill of the required length and diameter is not at hand. And this is where the tricks of home craftsmen come to the rescue, helping to cope with such a problem.

Such a long drill is rarely at hand

Option #1: Using machine oil

This method has a right to exist, but only partially. The fact is that regular oil will not solve the problem. The only thing that can help with this approach is solid oil or lithol. And then provided that the attachment point is hidden. The fact is that even if the head is thoroughly wiped after screwing in, over time the wood around the screw inside will begin to char, darken, and lubricant will begin to leak out. This will cause the paint at the location of the screw to swell. When wallpapering, this area may darken and grease may seep out.

If it doesn’t screw in, you can lubricate it with grease, but this is not advisable.

Option number 2: soap to help the master

This is a good way to screw a long self-tapping screw into wood without drilling. You just need to rub the thread with soap or dip it in a thick soap solution. After this procedure, the self-tapping screw will go in much easier. But even here there is a problem.

Soap contains caustic (especially a lot of it in household soap), which reacts with alloy steel, promoting the development of corrosion. Of course, this is not a quick process, but after a few years the rust will do its job. In any case, if the screw is screwed “dry”, after 2-3 years it can be easily unscrewed, but when installing using soap this will be problematic

Therefore, this method should be used with caution, having thought carefully beforehand.

Soap works great for screwing in screws, but problems may arise later

How to glue Self-adhesive on doors?

We separate the protective paper 10 centimeters from the edge and firmly press the sticky part of the self-adhesive to the door leaf, moving it to the upper end. Slowly peel off the paper and gradually glue the film, moving from top to bottom. At the same time, smooth the sticker with a rubber spatula or soft rag, expelling air bubbles.

Interesting materials:

What is included in the All Beeline family tariff? What is included in personnel management? What is included in the spring discharge kit? What's in a Whopper? What does the contract include? What does the concept of grammar include? What does specialized mathematics include? What does RChS include? What does Siberia include? What does the social structure of society include?

Video description

Securely level old floorboards

Construction foam

This material is most often used to seal joints between the wall and wooden boards on the floor. This option is also suitable for sealing large cracks and damage in the floor. Before using such a product, the surfaces of the gaps are moistened with water so that the liquid foam adheres better to the wood.

It is recommended to apply polyurethane foam in small quantities, as it tends to expand and subsequently the boards may begin to deform, which will negatively affect the plane of the floor.

Acrylic sealant

Sold in special tubes equipped with a syringe. Ideal for filling gaps between laminate and parquet joints, and eliminating spaces between dry boards.

After applying the composition, the boards will stop moving, the creaking will disappear, and it will be comfortable to move on the floor. The acrylic sealant on top can be painted with enamel or special paint for wooden floors.

Acrylic sealant for sealing cracks in wooden floors Source materik-m.ru