Many radio amateurs are not satisfied with the sound of industrial sound systems, so the problem of how to make a speaker amplifier with your own hands is an interesting one. There are many schemes that are suitable for repetition by beginning radio amateurs. They are assembled using accessible and inexpensive parts, are easy to manufacture and do not require complex setup. You can first make a sound amplifier of the simplest type , and then move on to more complex designs.

Powerful DIY sound amplifier

A radio amateur planning to make a low frequency (LF) system must resolve a number of the following issues:

- Element base

- Electrical parameters

- Scheme selection

Modern sound systems are assembled using bipolar or field-effect transistors and integrated circuits. Such designs do not require high voltage in the power supply circuits, are quite compact and provide a good range of reproducible frequencies and a low percentage of distortion. High-end audio equipment is assembled using vacuum tubes, which have not been used in mass-produced technology for a long time. Electrical parameters depend on the purpose for which the ULF will be used. The design, intended for connection to a tablet or computer, does not imply high quality sound reproduction.

For a specialist, it will be easy to assemble an audio amplifier with your own hands , providing fairly high parameters. In this design, you can use powerful transistors or microcircuits. The block can be designed to work with devices that produce a powerful output signal. Then a preliminary cascade is not required and it is enough to assemble only the tip. If the device is intended to work with a microphone, turntable or electric guitar, then you will have to assemble a complete path with a preliminary stage and tone controls. The easiest way to assemble a final power amplifier with your own hands This design is assembled on a simple printed circuit board, does not require adjustments or adjustments, and if assembled correctly it starts working immediately.

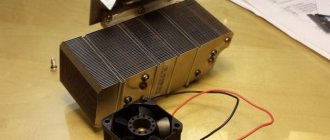

The design provides an output power of up to 20 watts per channel, operates from 10 to 18 V, so can be used in a car. This power is provided using the TDA1557 chip. The TDA8560Q can deliver up to 30 watts per channel. For more stable operation of the design when reproducing low frequencies, it is recommended to use 5 2200 µF capacitors connected in parallel in the power filter. The chip body gets very hot, so it needs to be installed on a radiator. To assemble a sound amplifier for speakers with your own hands, you will need a tester and a soldering iron. An oscilloscope and generator are not used for simple circuits.

FM antenna amplifier

I propose an antenna amplifier circuit for FM radio receivers.

As you know, outside the city, reception of radio stations in the FM range is extremely difficult. The signal level noticeably attenuates if there are any buildings or buildings in the path of the waves. To compensate for signal loss, it is necessary to raise the receiving antenna as high as possible, however, it is not always possible to achieve the desired result. A narrowband antenna amplifier will help to significantly change the situation for the better. This amplifier is equipped with a filter at the input, which allows it to block signals below 60 MHz and above 120 MHz, providing amplification only on the VHF band. Coils L1 and L2 are wound with PEL-2 wire with a diameter of 0.4 mm on a mandrel with a diameter of 4 mm. L1 contains 3.5 turns, L2 – 4.5 turns. The amplifier is powered by a voltage of 9-12 volts, while consuming a current of about 12 mA. Gain 18 dB. The amplifier can be wired in a metal case. Connections from the antenna to the amplifier and from the amplifier to the radio receiver are made with a shielded cable. Discuss on social networks and microblogs

Radio amateurs are interested in electrical circuits:

Please provide a circuit diagram for a medium-wave antenna amplifier.

Gray, as I understand it, you are talking about the amateur radio range of 1.8 MHz or 160 m. If so, then instead of an amplifier for the mid-wave range, try to calculate, design and use an EH antenna . According to radio amateurs, the efficiency, setup, ease of use and quality of reception and transmission of EH antennas are excellent. Moreover, using special programs, you can calculate an antenna for almost any desired frequency from a given range. An interesting fact is that the EH antenna is used underwater. Materials on EH antennas: Information: theory and practice of using EH antennas. Calculations: program for calculating EH antennas 1, program for calculating EH antennas 2

what the hell is om50 when you can make a regular frame antenna and put it on a higher mast

Assembled and connected... No result!

FM antenna amplifier. Make this amplifier directly on the Antenna and connect it to the receiver with an RK-75 cable.

thank you, the diagram is simple, but the effect amazed me; it amplifies the signal almost 75 km away; only the coils L1-L2 need to be moved apart a little and soldered together in a hinged form

Tell me if I replace KT 368AM with KT 372A, what else needs to be changed, if possible, correct the diagram

KT368A is not rated for noise at a frequency of 100 MHz. The gain at a 120 Ohm collector load is negligible. This “amplifier” will not amplify anything in the FM range.

How to assemble a sound amplifier

It makes no sense for beginning radio amateurs to undertake the task of repeating complex transistor circuits with high parameters. To adjust such structures, complex measuring equipment will be required. The easiest option for beginners would be to repeat circuits made using integrated components. To begin with, you can assemble a simple low-power audio amplifier .

The LM386 chip operates over a wide supply voltage range and provides power up to 1.2 watts into an 8 ohm load. The signal distortion coefficient does not exceed 0.2%. A variable resistor of 4.7 kOhm allows you to change the gain from 20 to 200. A homemade device can be assembled on a breadboard or mounted.

Project costs:

COMPONENTS:

| № | Name | Price, rub.) |

| 1 | Transformer (was available) | 3 000 |

| 2 | Textolite 200x300 | 500 |

| 3 | Parts for ULF TDA7293, power supply and input filter | 2 800 |

| 4 | Details for ULF Dorofeev | 600 |

| 5 | BP ULF Dorofeeva | 850 |

| 6 | Parts for AC protection device | 700 |

| 7 | Input selector on PGA2311 | 2 500 |

| 8 | I2C DAC (PiFi DAC) | 1100 |

| 9 | Raspberry Pi | 2500 |

| 10 | TVBox Tanix TX2 | 2600 |

| — | TOTAL COMPONENTS: | 17 150 |

CASE AND COMPONENTS:

| № | Name | Price, rub.) |

| 1 | Plywood 10 mm (sheet) | 850 |

| 2 | Oil | 350 |

| 3 | Potentiometer knob | 340 |

| 4 | Case fan | 170 |

| 5 | Connectors (BANANA) | 320 |

| 6 | HDMI extender | 120 |

| 7 | Case legs | 95 |

| 8 | RCA connectors | 115 |

| 9 | Power button | 210 |

| 10 | Subwoofer low pass filter | 130 |

| 11 | Front Panel Details | 200 |

| 12 | Fasteners | 300 |

| 13 | Wires, lugs, al.profiles (were in stock) | 500 |

| — | TOTAL CASE AND COMPONENTS: | 3600 |

TIME FOR MANUFACTURING AND ASSEMBLY

(days are still evenings, after work, sometimes weekends, but not full days)

| № | Name | Time (days) |

| 1 | Transformer rewinding | 2 |

| 2 | Manufacturing and assembly of ULF TDA7293 and PSU boards | 2 |

| 3 | Manufacturing and assembly of ULF Dorofeev boards | 2 |

| 4 | Manufacturing and assembly of power supply board (Dorofeev ULF) | 1 |

| 5 | Manufacturing and assembly of AC protection devices and input filter (2 pcs.) | 2 |

| 6 | Preliminary connection and testing of components | 3 |

| 7 | Making the case (3 days of which - oil coating) | 11 |

| 8 | Assembling components into the housing | 13 |

| — | TOTAL FOR MANUFACTURING AND ASSEMBLY: | 36 |

| add. | Preparation of the review | 3 |

More time was spent waiting for components and components; if you order cheaper, the delivery takes 2 months; sometimes a small thing slows down the whole process, although there was no need to rush.

PS We spent a long time celebrating the completion of work on the amplifier, but the cat went a little overboard:

DIY stereo sound amplifier

to assemble a high-quality stereo sound amplifier for speakers with your own hands , since such circuits require careful adjustment and debugging. There are circuits that provide high sound quality without complex settings. The proposed design is an ultra-linear circuit operating in class “A”. This means that the output signal is virtually undistorted and follows the shape of the input signal. Transistors KT803, KT805 or KT819 can be used in the output stage. From the output of the cascade you can get up to 15 watts of power, and the distortion is minimal and corresponds to the parameters of the highest class equipment.

A circuit operating in this mode consumes a lot of current, and the output transistors heat up in the absence of a signal, so they are installed on radiators. To make your own audio amplifier for stereo speakers, two circuits are assembled - for the right and left channels. If the design will be used for a car radio, then this circuit is sufficient. In other cases, a preliminary stage with gain, tone and stereo balance controls will be required. It is best to solder the audio amplifier on a printed circuit board. The output transistors are mounted on radiators. For reliable cooling, you can use a cooler from a computer power supply. Capacitor C2 must be film.

increase the power of a sound amplifier with your own hands by increasing the supply voltage by 10-15%. First you need to find out the critical voltage values for transistors. In some cases, increasing the input signal will help. This will drive the output stage more efficiently.

The question of how to make a powerful sound amplifier with your own hands often arises among radio amateurs with little experience. It makes no sense to take on a transistor circuit. It is difficult, time consuming and there is no guarantee that the design will work. It is best to use special microcircuits. An integrated ULF can output hundreds of watts, and the circuit does not need adjustment.

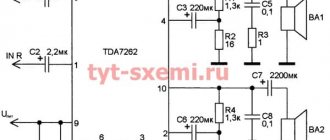

Three-channel multimedia UMZCH

Despite the many models of industrially produced multimedia speakers, the interest of radio amateurs in independently manufacturing such structures does not decrease. Systems with a common low-frequency channel are of particular interest. The low-frequency loudspeaker - subwoofer - is placed in a separate housing, which makes it possible to significantly reduce the dimensions of the speakers of the left and right channels. The amplifier described here with a total rated power of about 20 W is intended for this type of design.

Features of the multimedia complex include the relatively small size of the video monitor and the corresponding dimensions of the acoustic system, which is usually placed in close proximity to the listener. In this regard, the maximum power of amplifiers for such speakers usually does not exceed 10...20 W. The proximity of a multimedia speaker system often limits its permissible dimensions, so it is common to place a low-frequency head in one common housing - a subwoofer, and stereo speakers here act as “satellites”.

To generate the low-frequency (subwoofer) channel signal, a adder and an active filter are usually used. As an example in Fig. 1 shows a diagram of this unit.

Fig.1. LF signal conditioner (subwoofer)

The DA1.1 op-amp has an inverting adder combined with a first-order filter, and the DA1.2 op-amp has a second-order active Butterworth filter. The cutoff frequency of the resulting third-order filter is approximately 180 Hz. Divider R1R2 sets the op-amp mode for direct current. The frequency band of mid-high frequency loudspeakers (satellites) is limited by first-order filters at the input of the stereo UMZCH.

However, it is not at all necessary to use active filters to highlight the subwoofer frequency band. Two versions of UMZCH for a computer were published on the pages of the magazine [1], in which an original method of generating a signal for a subwoofer was used, which does not require a separate filter. Unfortunately, the first version of the design uses two different versions of the TDA1519 chip, which are not always commercially available. In the second option - hopelessly outdated TDA2005, which do not meet modern requirements in terms of distortion and noise levels; This chip requires a lot of external elements. By using modern UMZCH microcircuits designed for car radio equipment, you can somewhat simplify the circuit and significantly improve the performance characteristics of UMZCH.

The power amplifier is conveniently based on the common TDA1554Q chip (Philips). It includes two inverting and two non-inverting amplifiers with a gain of 20 dB each, their input impedance is 60 kOhm. There are two options for their inclusion. The first is standard, as a four-channel UMZCH with a maximum output power of 4x6 W (4x11 W) into a load of 4(2) Ohms. The second option is as a two-channel UMZCH in bridge connection with a maximum output power of 2x22 W into a 4 Ohm load.

In the proposed design, two inverting channels are used in a conventional connection, and two non-inverting channels, thanks to an original solution, are used in a bridge connection.

Amplifier parameters:

| Sensitivity, mV | 500 |

| Nominal load resistance, Ohm | 4 |

| Rated output power, W, MF-HF channels, LF channel | 2×3,5 12 |

| Maximum output power, W, channels MF—HF channel LF | 2×6 22 |

| Maximum current consumption, A | 3,5 |

| Cutoff frequency of MF-HF channels, Hz | 180 |

| LF channel cutoff frequency, Hz | 50…170 |

The amplifier supply voltage can be within the range of +10... 16 V. The current consumed by the device in the absence of a signal is no more than 0.1 A. In standby mode (remote shutdown mode) - 0.1 mA. Rated power is specified at a supply voltage of 15 V and harmonic distortion of approximately 0.5%. The maximum power, as is customary, is determined at a distortion of 10%.

The amplifier circuit is shown in Fig. 2. The device is simplified as much as possible, and the values of most elements are unified.

Fig.2. Amplifier circuit diagram

Volume and timbre are controlled by dual variable resistors VR1 and VR2, respectively. To avoid overloading the amplifier, the depth of tone control depends on the position of the volume control slider. At maximum volume, the rise in high frequencies does not exceed 2...3 dB (and that is due to the blocking of low frequencies and midranges), but increases to 5...6 dB at low volumes [2]. There is no provision for adjusting the treble tone to “blockage”, since, as practice shows, it is not necessary. Additionally, most PC sound cards have software-controlled tone and balance controls. If necessary, the tone control range in the amplifier can be increased to 12...14 dB by installing a variable resistor VR2 with a resistance of 10 kOhm. There is also the possibility of installing a stereo balance control (VR4), although its necessity is even more doubtful.

For installation reasons, inverting amplification channels are used for the satellites, therefore, to maintain the original phase of the signal, the dynamic heads BA1, BA2 are connected in reverse polarity. The total signal for the subwoofer is formed on a separating capacitor C13 common for two channels, as in [1]. The cutoff frequency of this filter is 170... 180 Hz. The capacitance of capacitor C13 is indicated for dynamic heads with an impedance of 4 ohms. For heads with an impedance of 8 ohms, its capacitance must be reduced to 220 µF.

In relation to satellite signals, the subwoofer signal is formed as an additional function, therefore, if certain conditions are met (more on this later), a “hump” at the crossover frequency of up to 3 dB may appear on the resulting frequency response. To eliminate this drawback, a tunable proportional-integrating filter VR3R1R2C3 was introduced into the subwoofer channel, the cutoff frequency of which varies in the range of 50 ... 150 Hz. When tuning the frequency, the signal level also changes at the same time, which makes it possible to abandon the usual level control in the subwoofer channel. In Fig. Figure 3 shows the theoretical frequency response of filters based on electrical voltage; The low-frequency channel family of curves is shifted down by 6 dB for convenience.

Fig.3. Theoretical frequency response of voltage filters

To ensure the operation of two identical amplifiers in a bridge connection, it is necessary to apply antiphase signals to their inputs. This design uses a load-sharing cascade. An inverted signal is removed from the collector of transistor VT1, and a non-inverted signal is removed from part of the emitter load. The gain of the cascade for both outputs is about -16 dB, so the voltage at the input of the low-frequency channel in the maximum wideband mode is approximately 4 dB higher than in the satellite channels. This compensates for the difference in sensitivity of the broadband and low-frequency heads and provides a reserve of level adjustment in the subwoofer channel.

In addition, this measure automatically eliminates overloading of the cascade on transistor VT1 at the input: due to the difference in gain, the signal limitation at the output of the bridge amplifier will begin earlier than at conventional outputs (where the signal for VT1 comes from). Thanks to the deep feedback through resistors R4, R5, the linearity of the cascade is satisfactory even at large signals. The DC cascade mode is ensured by connecting the VR3R1 circuit to capacitor C13. There is a constant voltage across this capacitor, approximately equal to half the supply voltage.

Another component that is still unusual for such amplifiers is the SA2 subwoofer signal phase switch. However, home theater systems and car subwoofers must have such a cascade. The need for its use is caused by the following: with a spatially separated acoustic system, the resulting frequency response at the listening point will be determined by the phase relationship of the incoming signals. The phase shift, in turn, is determined by the distance to the dynamic heads.

In Fig. Figure 4 shows the theoretical frequency response in the near field of radiation for the cases of in-phase and anti-phase switching of heads with their compact installation. Real frequency response in terms of sound pressure, depending on the distances and characteristics of the heads, can take even more bizarre forms. Obviously, the introduction of a phase switch allows you to more flexibly control the resulting frequency response.

Fig.4. Theoretical frequency response in the near field of radiation

Power switch SA1 controls the state of the microcircuit, and through it the supply voltage is supplied to the phase splitter stage. In the off state, the outputs are transferred to a high-impedance state, and the current consumption does not exceed 100 μA. The purpose of the remaining parts is obvious. The filter capacity is divided into two parts, since it is difficult to install a large capacitor directly near the power pins of the microcircuit.

About details and design. Oxide capacitors K50-35 or similar imported ones, capacitors C1, C2 are ceramic of any type, the rest are K73-17. All fixed resistors are MLT0.125. The variable volume control resistor should have an exponential dependence of the resistance on the angle of rotation (type B), the rest should have a linear dependence (type A). The KT315V transistor can be replaced with any np-p structure transistor with a base current transfer coefficient of at least 50. The choice of other parts is not critical.

The rectifier is made on KD213A pulse diodes, this will allow, if necessary, to significantly increase the filter capacity without the risk of multiplicative interference. Any network transformer can be used with an overall power of at least 80 W (preferably more), a permissible secondary winding current of at least 5 A and an output voltage of 9... 11 V.

Due to its relative simplicity, the amplifier can be assembled on a breadboard (in this version the author worked with it). For the magazine publication, a printed circuit board (Fig. 5) was developed, on which most of the parts are placed. The board is designed for installation of two-way P2K switches and the above-mentioned parts. Capacitor SZ with a capacity of 0.15 μF, if necessary, can be composed of capacitors with a capacity of 0.1 μF and 0.047 μF, for which additional contact pads are provided on the board.

Fig.5. Amplifier PCB

Variable resistors, connectors and a network transformer are placed outside the board. The jumpers in the signal circuit are made of thin installation wire; for installation of power circuits and speaker systems, it is necessary to use a wire with a cross-section of at least 0.75 mm2. The heat sink can be made from a 30x50 mm duralumin corner or used ready-made from a car radio (this is exactly what is used in the author’s version).

A properly assembled amplifier does not require adjustment. When turning on, it is enough to make sure that the voltages indicated on the diagram are present (permissible deviation ± 10%). In case of interference from the computer power supply, you should connect two ceramic capacitors with a capacity of 220...470 pF at the input of the microcircuit (between points 6, 7 of the board and the common wire). They can be placed on the side of the printed conductors.

To reproduce low frequencies, you need to use a specialized low-frequency dynamic head in an acoustic design. The easiest way is to use speakers from domestic household equipment, removing unnecessary parts. The author used AC S-30B (“Radio Engineering”) for testing. The acoustic design of satellites can be simple, including open.

Sources:

- Sapozhnikov M. Two simple UMZCH for a computer. - Radio, 2002, No. 4, p. 15.

- Shikhatov A. Passive tone controls. - Radio, 1999, No. 1, p. 14, 15.

List of radioelements

| Designation | Type | Denomination | Quantity | Note | Shop | My notepad |

| LF (subwoofer) signal conditioner. | ||||||

| DA1 | Chip | BA4560 | 1 | Search in the Otron store | To notepad | |

| C1, C6 | Electrolytic capacitor | 1 µF 16 V | 2 | Search in the Otron store | To notepad | |

| C2, C4 | Capacitor | 0.022 µF | 2 | Search in the Otron store | To notepad | |

| C3 | Electrolytic capacitor | 470 µF 16 V | 1 | Search in the Otron store | To notepad | |

| C5 | Capacitor | 0.01 µF | 1 | Search in the Otron store | To notepad | |

| R1 | Resistor | 39 kOhm | 1 | Search in the Otron store | To notepad | |

| R2 | Resistor | 56 kOhm | 1 | Search in the Otron store | To notepad | |

| R3, R4 | Resistor | 100 kOhm | 2 | Search in the Otron store | To notepad | |

| R5 | Resistor | 33 kOhm | 1 | Search in the Otron store | To notepad | |

| R6, R7 | Resistor | 47 kOhm | 2 | Search in the Otron store | To notepad | |

| R8 | Resistor | 470 Ohm | 1 | Search in the Otron store | To notepad | |

| Amplifier circuit. | ||||||

| DA1 | Chip | TDA1554Q | 1 | Search in the Otron store | To notepad | |

| VT1 | Bipolar transistor | KT315V | 1 | Search in the Otron store | To notepad | |

| VD1-VD4 | Diode | KD213A | 4 | Search in the Otron store | To notepad | |

| C1, C2 | Capacitor | 470 pF | 2 | Search in the Otron store | To notepad | |

| C3 | Capacitor | 0.15 µF | 1 | Search in the Otron store | To notepad | |

| C4, C11, C13 | Electrolytic capacitor | 470 µF 16 V | 3 | Search in the Otron store | To notepad | |

| C5-C8, C10 | Capacitor | 0.1 µF | 5 | Search in the Otron store | To notepad | |

| C9 | Electrolytic capacitor | 100 µF 16 V | 1 | Search in the Otron store | To notepad | |

| C12 | Electrolytic capacitor | 4700 µF 25 V | 1 | Search in the Otron store | To notepad | |

| VR1, VR2 | Dual variable resistor | 47 kOhm | 2 | Search in the Otron store | To notepad | |

| VR3, VR4 | Variable resistor | 47 kOhm | 2 | Search in the Otron store | To notepad | |

| R1, R4, R7, R8 | Resistor | 4.7 kOhm | 4 | Search in the Otron store | To notepad | |

| R2, R3, R5 | Resistor | 1 kOhm | 3 | Search in the Otron store | To notepad | |

| R6 | Resistor | 100 Ohm | 1 | Search in the Otron store | To notepad | |

| BA1-BA3 | Speaker | 4 ohm | 3 | Search in the Otron store | To notepad | |

| Add all | ||||||

Tags:

- ULF

DIY speaker amplifier for dummies

Typically, designs with high output power are used for subwoofers, but if there are powerful speaker systems, then such a design can be used for sounding large rooms. Such ULFs require a properly selected power source, and for correct operation you need to consider cooling the output stages or the housing of a powerful microcircuit.

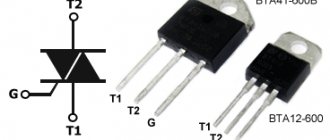

A simple high-power low-frequency block circuit can be assembled using several types of integrated circuits, but the pin numbering does not change. Output power (W) corresponds to the following types of chips:

- PA01 – 50

- OPA12 – 60

- TSC1468 – 120

- PA04 – 400

- PA03 – 1000

Homemade sound amplifiers , made with your own hands using serviceable elements and careful installation, can provide good parameters. The structure is powered from a bipolar power source with a voltage of 15 to 45 volts. In addition to PA01, the maximum voltage for which should not exceed 28 volts. Broadband speakers are used as a load, since the amplitude-frequency response is quite linear in the range of 10 Hz-40 kHz. The coefficient of nonlinear distortion at a frequency of 1 kHz and an output power of 50 watts does not exceed 0.005%. Despite the fact that the microcircuits are quite expensive, you can use them to assemble a good sound amplifier .

↑ Three-channel amplifier circuit

It was decided to start with 3 channels on single-ended circuits.

Fragment excluded. The full version of the article is available to patrons and full members of the community. Read the terms of access.

I decided to heat the preamplifier and output tubes with direct current. The ECC83S lamp heater operates from a stable voltage of +12.6V. You may have already seen a similar rectifier circuit more than once in my articles, but I’ll repeat it again - you need to solder a diode to the middle leg of the 7812 stabilizer, the voltage drop across which will be 0.6V, which is added to the main 12V output and the result is 12.6V. The current consumption of three ECC83S lamps is 450mA, so installing a heatsink on the 7812 chip is mandatory.

He initially planned to heat the 6P14P output lamps using a 5A adjustable stabilizer, but having approximately calculated the minimum required radiator area at a current of 3A, he abandoned this idea due to its bulkiness. Therefore, I simply assembled a rectifier with a filter. The separation of the primary and secondary filter is carried out by the KD213 diode. The filament output voltage under load is 6V.

The anode supply is organized by a classic U-shaped filter “capacity 100 uF – choke – capacity 220 uF”. In my opinion, this is quite sufficient if there is a D-47 throttle.

The circuit itself is the simplest - “preamplifier - emitter follower - terminal”. The signal level is adjusted using potentiometers located in the gap between the preamplifier and the emitter follower. The level adjustment of the central channel is connected to one potentiometer, but the two rear channels are connected to one dual potentiometer to simultaneously adjust the levels.

DIY mini sound amplifier for speakers

Such a design should have a small number of accessible parts, be easy to assemble and not require adjustment. Common and inexpensive microcircuits are best suited for this purpose. They are used in commercial equipment, but they can be used for homemade projects. The design will be able to provide an output power sufficient to sound a medium-sized room. How to make the simplest sound amplifier with your own hands will be clear after reading this article.

to assemble a simple mini sound amplifier with your own hands, using a ready-made module with a RAM8403 chip. This design will not require any discrete elements, since they are provided in the circuit. All you need to do is connect the speakers, power and apply the input signal. The speaker impedance should be 6-8 ohms. Output power reaches 2 watts per channel.

How to determine if the signal is weak

You should install a car antenna amplifier only if the signal level is low. The main features can be called:

- Frequent interference.

- Sound distortion when listening to a radio station.

- Lost image synchronization.

- Periodic complete disappearance of the signal.

For a radio, an amplifier is a device that can increase the signal level. In this case, the transmission quality can be doubled. You can install the device yourself, there are no problems with this.

Reasons for a bad signal

The amplifier for the car antenna is selected taking into account the reason that led to the problem. The main ones can be called:

- Malfunction of the antenna and other elements. High humidity often causes oxide to form, which impairs contact.

- Hissing and wheezing while listening to the radio indicates a malfunction of the receiver itself. In most cases, the problem is a cracked circuit board.

- Additional interference degrades the signal quality in the car. They can be created by mobile operator towers, power plants, and railway tracks.

- Moving away from the signal source also causes a decrease in the quality of reception.

- Additional interference may be created when the recorder is connected to a power source via the cigarette lighter. This problem can be solved by installing equipment that runs on a built-in battery.

In most cases, artificial interference and distance from the source cause signal deterioration. It is recommended to amplify the radio in case of frequent long trips.

Complete DIY sound amplifier

A complete audio amplifier consists of a pre-stage and a final stage, which can be implemented using transistors or integrated circuits. To assemble an audio amplifier with your own hands, you need to have experience and the necessary technical equipment, since it is impossible to set up such a design without measuring instruments. Block diagram of a full amplifier.

Adjustment of the device can only be performed by an experienced radio amateur. The figure shows the diagram of one input channel. The stereophonic path includes two such circuits. This stage with active tone controls and volume control with compensation can be connected to any final stage. The pre-stage is assembled using a dual high-speed operational amplifier LM833 and a TL071. Instead, you can use op-amp 544 series.

↑ System architecture 5.1

As you can see in the figure, a 5.1 system consists of a rear pair of speakers, a front pair, a center speaker and a subwoofer.

For comfortable use of this system, it is necessary to correctly place the speakers in the room and maintain the power ratio between them. Such systems are used for dubbing films, games, music, in general, anything that has a 6-channel separation of tracks. In the case of films and games, sound tracks are output to the speakers according to the following principle: front pair - main sound effects, voices on the right and left, center speaker - voice, rear pair - background effects, subwoofer - bass component of the effects. The balance of the entire system is very important so that the side voice does not drown out the central one, or the background effects do not interrupt the front ones.

Having understood this principle, I moved on to the problem of power. I planned to install this system in the hall, roughly figured out where which speakers would be placed, and moved directly to the problem of power. From my own experience, I know that when you turn on a 10 Watt terminal at full power, the room becomes somewhat uncomfortable. As a result, it was decided to make the front pair on push-pull circuits with 6P14P output lamps with a power of 10 W, and the central speaker and rear pair on single-cycle circuits with the same 6P14P output. The subwoofer was a separate issue for me, since I already had a 40-watt tube end, all I had to do was come up with a driver for it.

The power supply for five ECC83S and seven 6P14P lamps promised to be quite bulky. Having thought about what and how many transformers are needed for this task, I went in search of treasures. These treasures were collected in about a week. I managed to get TN-60 for filament of all lamps, two TA-166 for the anode and three D-47 chokes for filters. This pleasure did not come cheap, but I knew what I was getting into when I conceived this project.

Everyone usually starts with the case, but I decided for myself that I would first make the boards, and then weld a box of iron sheets for them, into which everything would fit.

Simple DIY audio amplifier

The simplest do-it-yourself sound amplifier is assembled using a TDA7231 chip . The presented circuit provides an output power of up to 1.5 watts into a four-ohm load. The microcircuit has a large acceptable power supply range, so ULF can be used in battery designs. The device's quiescent current does not exceed 8 mA. The current consumption at maximum power reaches 1.5 A. Any dynamic head with a resistance of 4 Ohms can be connected to the device. This design is not suitable for high-quality music playback due to the high percentage of distortion, which reaches 8% at maximum volume. The device can be used in self-powered electronic toys or security alarm systems.

A simple audio amplifier for home is easily assembled on a 4069 chip, which contains 6 inverters. The system is suitable for connecting headphones when listening to music files from a computer, phone or tablet. A simple circuit provides satisfactory parameters.

By changing the resistance of resistors R2 and R3, you can change the gain of the device. For this ULF it is not necessary to make a printed circuit board. A standard breadboard with plated holes will do.

There are many simple designs that can be repeated by radio amateurs with little experience. To manufacture such devices, you only need a tester to check the main circuits. After you gain experience in the process of manufacturing and setting up simple circuits, you can move on to more complex systems.

CHAPTER 2. Amplifier housing.

I built TDA7293 amplifiers and purchased an input selector 4 years ago.

I developed the idea for a case, but basically it was a design made of an aluminum front panel and walls and a top cover made of oak lamellas. It was an almost classic design, easy to make, but during the suspension of the project I was so tired of this design, I always had the feeling that I had seen this somewhere many times and had already had my fill. Therefore, in view of the recent “disease” with the end cut of plywood, the following design was invented:

The case is made of a set of plywood rectangular rings, a one-piece removable top cover, the base of the case is an aluminum sheet, the front panel is darkened plexiglass. My amplifier will be placed on a low hanging cabinet, so its rear part is clearly visible from above. I don’t really like all this heap of cables on the back of devices, long connectors, so in the back of the case I made a small recess in which the input connectors of the connected cables will be hidden. Of course, not everything will be completely hidden, but at least it will be better.

This should be the final look:

To make the structure, a sheet of 10 mm sanded plywood was purchased. Half of this sheet was also spent on the bookshelf speakers from my other review.

Since the workshop is very small, cutting a whole sheet of plywood on a sawing table is not possible. I first divide the sheet into 2-3 parts with a jigsaw. We cut 10 rectangular sheets of plywood, measuring 400 mm x 300 mm.

We set aside the top and bottom sheets, and mark and cut out windows in the eight central sheets with a jigsaw. The wall thickness of each ring is 10 mm.

Glue the 8 resulting rectangular rings together. press on top and bottom with the remaining sheets and tighten with clamps. I use PVA glue Moment Joiner Super.

In the lower part, the window in the sheet is somewhat different; there it is necessary to provide a shelf to deepen the rear panel, as well as a slightly larger thickness of the side walls, which will later be milled to fit the aluminum base.

In the main part of the body, on the sawing table we saw off the back wall for the rear panel, and glue the main part of the body to the lower part.

To fasten the top cover, I chose black M4 bolts with an internal hex head. I made the recesses in the cover for the bolt head in the same way as for the bookshelf speakers from another review, using a 7 mm wood drill, and then a 4.2 mm drill all the way through.

On the side of the body, we glue plywood cubes to the walls, into which we then place mustache nuts (they will be shown in the photo below). Also in the photo you can already see the walls of the rear niche. I cut them out from a large piece that was left over from the sawn-off back of the body. Glued it on PVA.

Then we take an angle grinder in our hands, with a Velcro attachment and a grinding wheel with 80 grit, draw the radii of curvatures of the case on the top cover, and perpendicular to the plane of the top cover we actively work on creating curves at the corners of the case. We also sand the transitions between layers of plywood sheets on the walls of the case, since mistakes were made during gluing (in the photo above you can see that the parts shifted during gluing, I saw it too late, I don’t know how I missed it), but an angle grinder with such a wheel will correct any mistakes , fortunately there is a large margin in the thickness of the case walls))

By the way, beforehand, after gluing the 8 plywood rings of the body, I also used an angle grinder and a wheel with 80 grit to level the inner walls of the body to an even, smooth state. When working with 80 grit, there are both advantages - the speed of work - and disadvantages - scratches. More about the disadvantages a little later.

Amplifier base.

We saw a sheet of aluminum, 4 mm thick and dimensions 380x280. We apply it to the lower part of the body and draw radii. We grind the radii with an angle grinder / Dremel.

We apply the resulting base and trace with a pencil along the bottom of the body.

We take a router with a groove cutter in our hands and make a 4 mm recess for our base. It didn’t turn out very neatly, there’s nowhere to put the base of the router, all the work is almost suspended, the router tends to cut itself, we need tools to expand the base of the router.

We try on the base, mark, drill and countersink holes for attaching the base to the body

It is necessary to cut a window under the front plexiglass front panel. We print out the window from the drawing on a scale of 1:1, glue it onto a piece of cardboard, cut it out with a scalpel, and glue it to the body with double-sided tape.

We cut out the resulting window with a jigsaw.

Now we need to trim the edges of the window. We also do this with an angle grinder and a circle with 180 grit. Of course, you can do this with a router, but for me it takes longer, and you need good skill, here again there is not enough space for the sole of the router, and there are a lot of straight sections, without a stop I can ruin it. Using an angle grinder, with careful soft movements, we draw straight lines and window radii.

We try on the top cover and use a compass to draw a semicircle of recess for the future volume encoder button.

For the front panel, I considered different options. It should be dark so that the LCD display of the output selector can be seen through it, as well as the control panels of the selector and TV set-top box, but at the same time, the insides of the amplifier should not be visible. There was an option to order a piece of glass and tint it, but the mounting holes had to be very close to the edges, and it seemed that it would be expensive, but honestly I didn’t find out the price. Plexiglas is easier with it, but there are a lot of reviews that it doesn’t work well with the tint film, bubbles appear. I tried the option with tinting varnish, but it is very cloudy, the inscriptions on the LCD display are very cloudy. So I chose another option. Two thin sheets of plexiglass, between them a piece of tint film, this “sandwich” and screwed to the body. During the search for thin plexiglass, I was offered to immediately cut out the parts according to my drawing, since they still cut with a laser cutter, and for 200 rubles. I received these two parts already with holes.

But in fact, as it turned out, I received the parts not from plexiglass (acrylic), but from transparent PET 2 mm thick.

I received a piece of film from an auto-tinting company as a gift, with a light transmittance of 30%; this turned out to be optimal for a bright image of the output selector screen and hiding the insides of the amplifier.

Since PET is not particularly afraid of the tint film, I simply glued it to one of the parts and covered the second one on top. I placed a few drops of superglue on top at several points so that the resulting glass would not peel off and dust would not get in there.

When fitting the transparent panel to the body, a small problem was identified. The top cover of the case turned out to be slightly curved, it is not visible to the eye, but there is a hump of 1-1.5 mm upwards. Because of this, the upper extreme points of the panel rested against the housing cover, and in the middle there was a gap between the panel and the housing cover. You cannot buy flat plywood from us. There were two solutions: 1. Sand the front panel under the top cover. But PET is a bit viscous material, I was generally afraid of ruining the finished parts. 2. Make a groove in the top cover. I thought that this option was better, simpler, and as a plus I would fix the panel in the upper part, in a groove, relative to the body. You need to make a groove with a router, the groove is only 4 mm, I have a milling attachment for Dremel, but I had to go find it and get it from the closet, unfasten the flexible shaft, put on the Dremel, and screw on the inconvenient bottom nut. I decided that there was too much work for a simple shallow hidden groove and decided to do it by hand like this:

A thin cutter into a flexible shaft, two steel rulers as a limiter for the cutter’s stroke, and with “muscular” control of the depth of entry of the cutter, we quickly make a groove. Problem solved.

Next we move on to the volume encoder knob. I ordered this pen: 4pcs aluminum plastic knob potentiometer knob 48*19mm potentiometer cap Volume knob switch cap Encoder for amplifier. Diameter - 48 mm.

The diameter of the recess for the handle in the body is 50 mm in diameter and 7 mm in depth. We fasten the housing with the top cover to the table with clamps, place the router and make a recess for the encoder handle and try on the handle.

I took the following power button: [1 pc. Colorful Useful Durable 22mm LED Power Push Button Switch Momentary/Latching Waterproof Metal Self Locking Stainless Buy on AliExpress] Thread diameter is 22mm. The button has a high pressure part; when pressed, the finger does not fall further than the front surface of the button. The hole in the body was made with a step drill.

Next, we take a grinder, grinding wheels with 220 grit, and diligently sand the body. We even grind very diligently, because, as it turned out, it is necessary to remove all the defects from the work of the grinding wheel with 80 grit.

In the photo below you can see the body prepared for oil coating. This is already the second attempt, the first one was unsuccessful, the oil “revealed” all the transverse deep scratches from the coarse grain, they are just not visible on the cut of the plywood. I had to remove the oil and polish it more thoroughly.

After final sanding, coat the body with oil. As the first layer I used BIOFA tinting oil. Dark brown color, apply in a thin layer so as not to lose the texture.

Cover the second layer with BELINKA INTERIER oil. It will give the body a golden hue, as well as a pleasant shine, like oil with wax. Apply this oil in two layers, removing excess.

Next, polish the body with a wool wheel.

We fasten the front panel from the inside of the case with small self-tapping screws.

The hole for the encoder shaft was made with a 7mm drill. On the reverse side, the encoder housing is pressed against the front panel. We install the encoder knob and the power button.

The body is ready!

How to install and connect

After assembling the product, it should be connected. Recommendations for carrying out such work are as follows:

- The external antenna is connected to the amplifier input. For this, a cable with a resistance of at least 75 Ohms is used.

- It is recommended to insulate the cable. Do not forget that high humidity causes the appearance of oxide. At the same time, it is secured with clamps, since strong vibration may occur when moving.

- When connecting, polarity must be strictly observed.

- The power supply requires 12V voltage, which is often used in the car. The board is connected to the ANT radio output. Due to this, voltage will be supplied when the device is turned on.

- When installing the device outside the vehicle, ensure high-quality sealing of the housing. Moisture getting inside the device will cause corrosion.

The advantage of a homemade device is that it can be disassembled and changed at almost any time. By selecting a suitable circuit, the amount of interference is reduced.

- Bolle masks

- kids t shirts for boys

- sewing machine shop

About power supplies

At least two articles have already been written about the power supply for the amplifier: Power supply for TDA7293 and TDA7294 and Power supply for the amplifier - circuit and operation. The second of them examines in detail the structure of the power supply and the operation of its components. The power supply circuits that are described in the articles are actually excellent, they work well, and it is according to them that the vast majority of power supplies are built, both in homemade and industrial equipment. What will happen here? Here I want to give a practical circuit for a “flawless” power supply for an amplifier.

“Impeccable” does not mean “the most perfect” or “the best.” And not only because for some, “the best” is one with a built-in coffee machine. This power supply optimally (and not at all maximally!) eliminates all errors, interference and instabilities. So, to get power quality, not ideal, but sufficient for excellent operation of almost any amplifier.

A typical power supply circuit is given in the article Amplifier Power Supply and shown in Fig. 1. This is an excellent power supply, implemented in a similar form in a huge number of devices. The transformer divides it into two parts: to the left of the transformer is the high-voltage part, connected to the AC network, and to the right is the low-voltage part, connected to the amplifier.

Rice. 1. Amplifier power supply diagram.

The high-voltage part of the power supply must contain a fuse and a power switch. It is also highly advisable to use a surge protector. Typically, using a noise suppression capacitor gives fairly good results. Moreover, I highly recommend using it.

A more complex filter can be used, but with caution - depending on the filter circuit and the presence or absence of grounding of the case, a complex “correct” filter can create problems: the case may be under mains voltage when communicating through Y-capacitors. In addition, it is necessary to correctly estimate the current consumed by the amplifier from the network, otherwise the filter will be overloaded with current and its efficiency will be significantly reduced. In addition, ready-made assembled filters are quite expensive, and when assembling a filter from separate components, there is a chance of making mistakes in their correct use.

We'll talk about good network filters another time. For now, we’ll make do with one noise-suppressing capacitor, which is usually quite sufficient.

Therefore, let's deal with the part that is located to the right of the transformer - the low-voltage one. The work of this part is more important.